Method for preparing high quality Antarctic krill oil rich in phosphatidylserine containing polyunsaturated double-bonded fatty acyl

A technology of phosphatidylserine and Antarctic krill oil, which is applied in the directions of producing fat, edible oil/fat, and fat oil/fat production, etc., can solve the problems of limited source of raw materials, unfavorable quality, low effective content, etc., and achieves simple and practical reaction, The effect of increasing the content and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

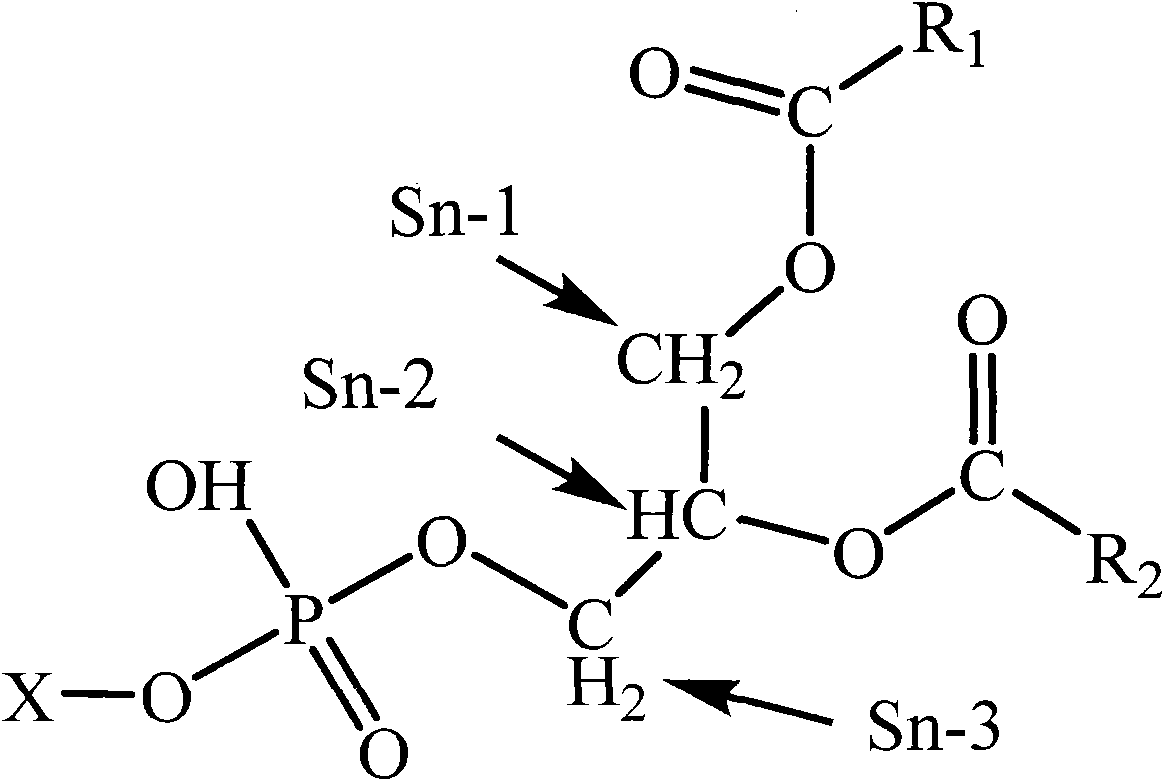

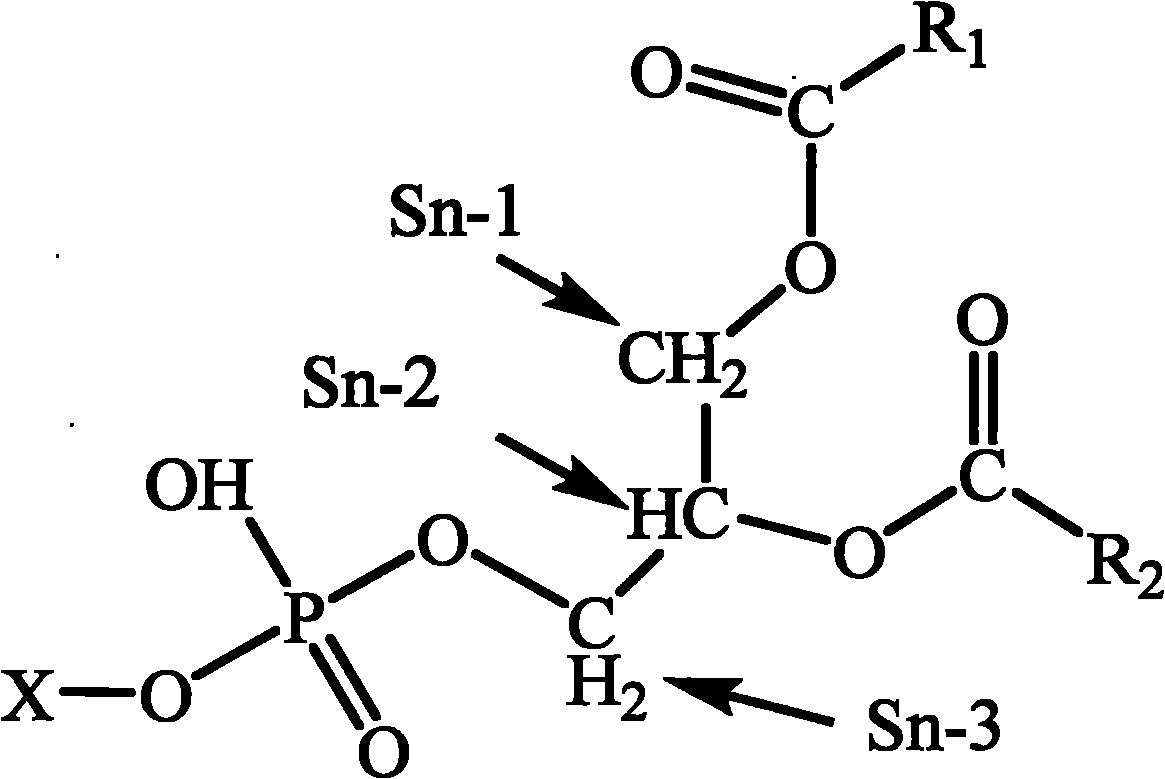

[0072] Example 1: Extraction of phosphatidylcholine rich in polyunsaturated double bond fatty acyl groups.

[0073] Weigh 20 kg of Antarctic krill oil, which contains 19.3% of EPA in phospholipids, 11.5% of DHA, 36.3% of PC, 1.5% of phosphatidylserine, and 40 liters of acetone. Add the above two raw materials to 100 Liter reactor, fill the reactor with nitrogen, under zero degrees Celsius, continuous mechanical stirring, 80

[0074] rpm, react for 2 to 15 hours, end the reaction, filter, freeze-dry the solid to obtain 13 kg of phosphatidylcholine rich in polyunsaturated double bond fatty acyl groups, of which: EPA is 18.3%, DHA is 8.1%, and the content of PC is 47.8%, the content of phosphatidylserine was 2.4%, and the filtrate was concentrated under reduced pressure at 20 degrees Celsius to remove the solvent to obtain 7 kg of red-brown oil.

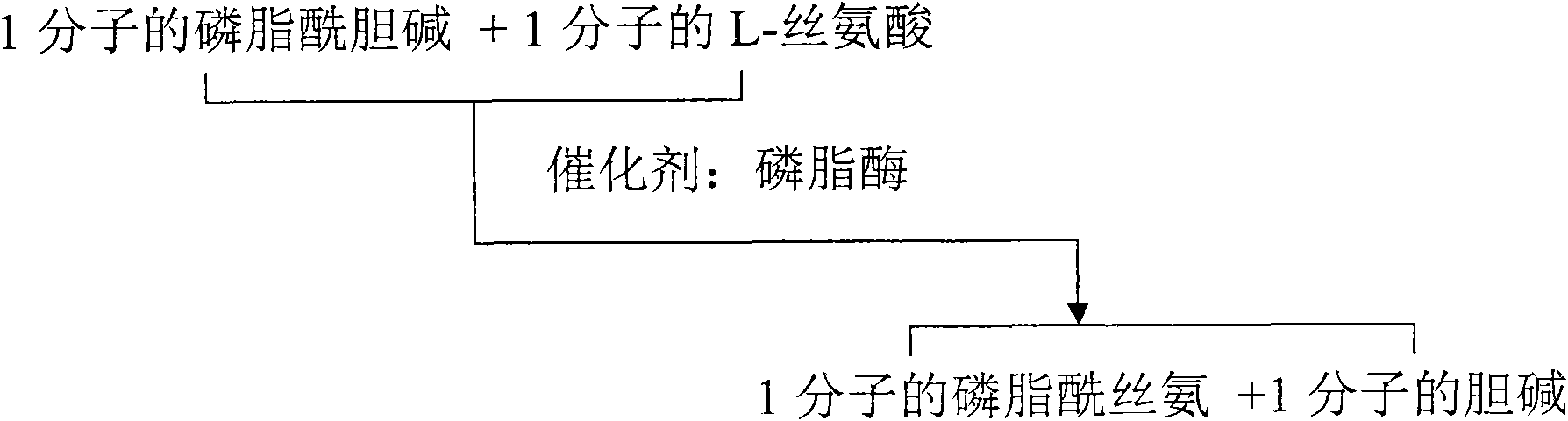

Embodiment 2

[0075] Example 2: Refined Antarctic krill oil rich in phosphatidylserine

[0076] Weigh 10 kg of Antarctic krill oil, which contains 19.3% of EPA in phospholipids, 11.5% of DHA, 36.3% of PC, 1.5% of phosphatidylserine, 4 to 6 kg of L-serine, 0.1 to 0.8 kg Calcium chloride, 20 liters to 100 liters of water buffer in the range of pH 5.5 to pH 8.5, was added to a 150 liter reactor, under the protection of nitrogen, 0.1 to 1 liter of phospholipase D (about 20,000 to 50 Ten thousand units), within the range of 45-53 degrees Celsius, continuous mechanical stirring, 100rpm, reaction for 2 to 15 hours, stop stirring, end the reaction, add 10 to 50 kg of acetone, and then add 10 to 50 kg of n-heptane, continue mechanical stirring, 30rpm, 0.5 hours later, stop stirring, let stand for layering, take the organic phase, repeat the extraction 2 to 3 times according to the aforementioned method, gather the organic extracts, concentrate under reduced pressure at 20 degrees Celsius to obtain 9.5 ...

Embodiment 3

[0077] Example 3: Phosphatidylserine products rich in polyunsaturated double bond fatty acyl groups

[0078] Weigh 10 kg of Antarctic krill phosphatidylcholine prepared in Example 1. Among them, the phospholipid contains 18.3% of EPA, 8.1% of DHA, 47.8% of PC, 2.4% of phosphatidylserine, and 12 to 20 kg. L-serine, 0.4-1.5 kg calcium chloride, 50 liters to 120 liters of water buffer in the range of pH 5.5 to pH 8.5, added to a 150 liter reactor, under the protection of nitrogen, put in 0.1 to 2 liters of phospholipids Enzyme D 1 million units, within the range of 45-53 degrees Celsius, continuous mechanical stirring, 100rpm, reaction for 2 to 15 hours, to end the reaction, add 10 to 60 kg of ethanol, 10 to 60 kg of n-hexane, continuous mechanical stirring, 30 rpm, 0.5 After hours, stop stirring, let stand for layering, take the organic phase, repeat the extraction according to the aforementioned method for 2 to 4 times, pool the organic extracts, concentrate under reduced pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com