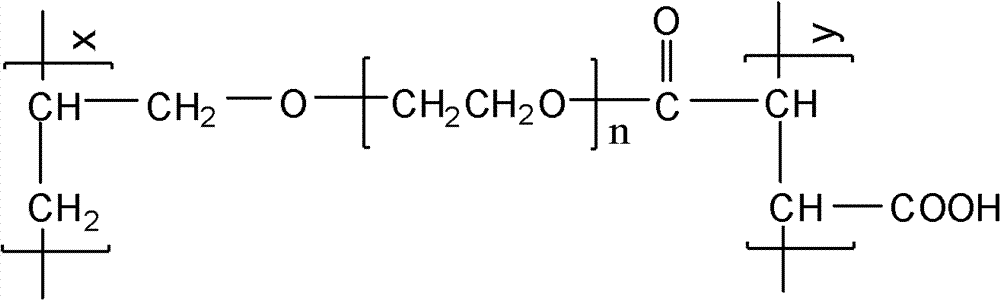

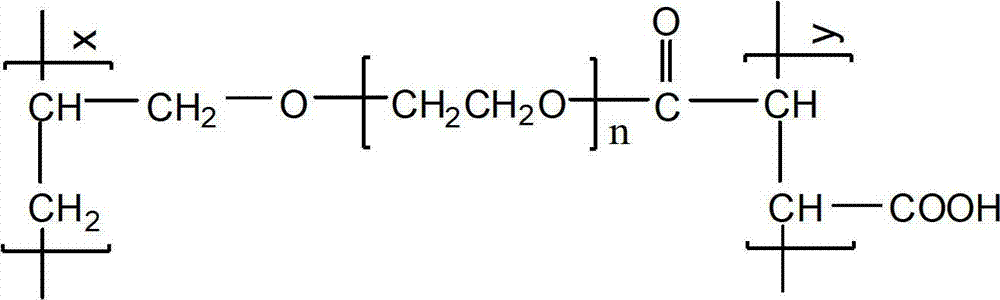

Green environment-friendly corrosion and scale inhibiting dispersant and its preparation method

A corrosion and scale inhibition, green and environmental protection technology, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc., can solve the poor effect of calcium sulfate scale inhibition, calcium phosphate scale and iron oxide Problems such as poor particle inhibition and dispersion, poor calcium phosphate resistance, etc., to achieve the effect of green and environment-friendly preparation process, good biodegradability, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0017] Example 1: at N 2 Add 100g of allyl polyethylene glycol monoether to the protected reaction kettle, add 100g of maleic anhydride and react at 60°C for 2.5h to obtain a polyether carboxylic acid reaction monomer; add 100g of water, mix well and adjust the temperature to At 70°C, add 12g of sodium persulfate (dissolved in 50g of water) dropwise. After 2 hours of dropwise addition, raise the temperature to 80°C and continue the reaction for 3 hours. APEYY).

[0018] When the dosage of the obtained APEYY is 8mg / L, the Ca 3 (PO 4 ) 2 Scale inhibition rate can reach 99.3%, for CaCO 3 Scale inhibition rate is 97.1%, for CaSO 4 The scale inhibition rate is 96.5%, the light transmittance of the Fe(III) solution which characterizes the performance of dispersing iron is 14.9%, and the corrosion inhibition rate for carbon steel can reach 93.7%.

example 2

[0019] Example 2: at N 2 Add 150g of allyl polyethylene glycol monoether and 120g of maleic anhydride to the protected reactor to react for 3 hours at 70°C to obtain a polyether carboxylic acid reaction monomer; add 150g of water, mix well and adjust the temperature to 75°C ℃, then dropwise add 12g of potassium persulfate (6g) and sodium persulfate (6g) mixture (dissolved in 50g of water), after the dropwise addition, raise the temperature to 90°C, continue the reaction for 5h, and after cooling down to room temperature, obtained Green and environment-friendly polyether corrosion and scale inhibitor dispersant (APEYY).

[0020] When the obtained APEYY dosage is 8mg / L, to Ca 3 (PO 4 ) 2 Scale inhibition rate up to 99.7%, for CaCO 3 Scale inhibition rate is 91.5%, for CaSO 4 The scale inhibition rate is 94.3%. , The light transmittance of Fe(III) solution, which characterizes the performance of dispersing iron, is 16.1%, and the corrosion inhibition rate of carbon steel ca...

example 3

[0021] Example 3: at N 2 Add 120g of allyl polyethylene glycol monoether and 130g of maleic anhydride to the protected reactor to react at 100°C for 2 hours, add 180g of water, adjust the temperature to 80°C after mixing, and then dropwise add 10g of sodium persulfate ( dissolved in 60g water), after the dropwise addition, the temperature was raised to 95°C, and the reaction was continued for 2 hours, and after cooling down to room temperature, a green and environment-friendly polyether corrosion and scale inhibitor dispersant (APEYY) was prepared.

[0022] When the obtained APEYY dosage is 8mg / L, to Ca 3 (PO 4 ) 2Scale inhibition rate up to 96.5%, for CaCO 3 Scale inhibition rate is 90.7%, for CaSO 4 The scale inhibition rate is 92.7%, the light transmittance of Fe(III) solution, which characterizes the performance of dispersing iron, is 16.2%, and the corrosion inhibition rate of carbon steel can reach 94.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com