Nanometer barium-strontium titanate medium energy storage material coated by aluminum-silicon composite oxide and preparation method thereof

A composite oxide, barium strontium titanate technology, applied in the field of electronic materials and devices, can solve the problems of lattice mismatch, poor particle uniformity, low dielectric constant of the sample, and achieve stable dielectric constant, lower reaction temperature, The effect of improving the breakdown electric field strength and temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

[0064] 1) Preparation of Ba 0.4 Sr 0.6 TiO 3 Powder, using the liquid phase alkoxide reaction method, choose Ba(OH) 2 ·8H 2 O, Ti(OBu) 4 (98%, provided by Sinopharm Chemical Reagent Co., Ltd.) and Sr(OH) 2 ·8H 2 O (99%, Alpha Company) is the main raw material, according to a certain Ba / Sr / Ti=4:6:10 molar ratio batching. First put a good amount of Ba(OH) 2 ·8H 2 O and Sr(OH) 2 ·8H 2 O was 30.901g, 25.770g was dissolved in 250ml deionized water at 80°C in a water bath to form solution A; then 66.693g of Ti(OBu) 4 Add it into 250ml ethanol solution, stir and dissolve it for 2 hours, and make solution B for later use.

[0065] 2) Slowly add solution B dropwise to solution A and vigorously stir for 2 hours, then filter the white precipitate. Dry the white precipitate at 100°C and then heat-treat it at 600°C, then ball mill it with zirconia balls and absolute ethanol for 20-24 hours, and then dry it to get Ba 0.4 Sr 0.6 TiO 3 Nano powder (~50nm) is used for later use....

Embodiment 1

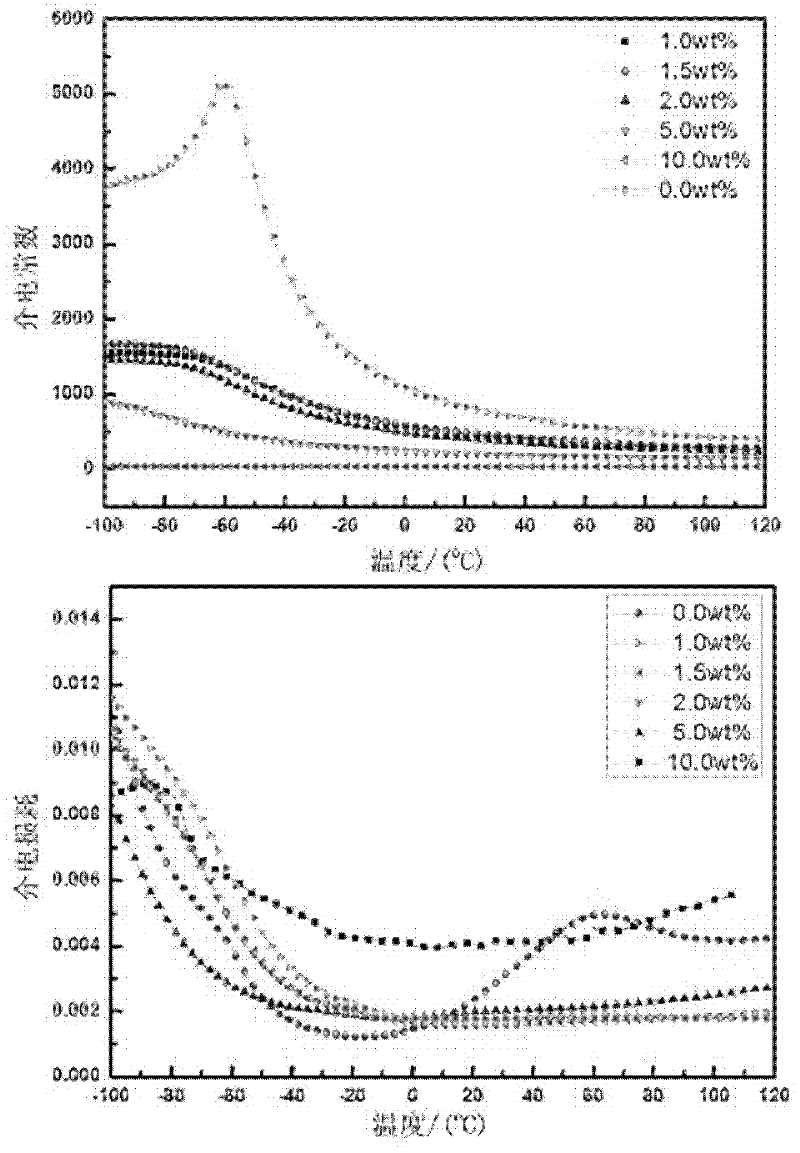

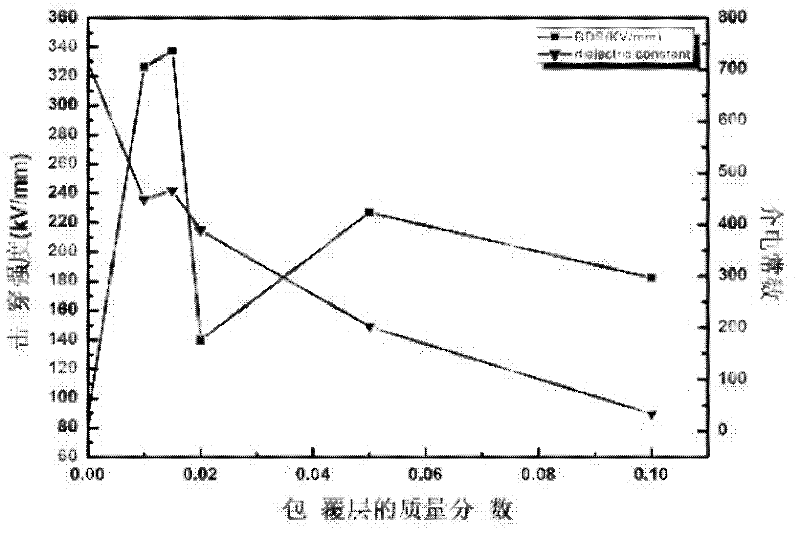

[0072] Example 1 # -5 # The dielectric constant and loss versus temperature curves of the dielectric storage material made by the formula are as follows: figure 1 Shown; Example 1 # -5 # The relational curve of the breakdown electric field intensity and coating mass fraction of the medium storage material that formula is made is as figure 2 shown.

[0073] After testing, Example 6 # -7 # The relationship between dielectric constant and loss and temperature of the medium storage material made by formula is closer to example 1 # -5 # The formulation of the corresponding components, but its breakdown electric field strength and energy storage density decreased slightly.

[0074] Depend on figure 1 It can be seen from the dielectric thermogram that the Curie temperature and dielectric constant of this type of composite ceramic material can be effectively adjusted by controlling the ratio of the cladding layer in the composite material system, and a composite medium with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com