Method for producing small peptide amino acid microelement chelate by way of acid hydrolysis of protein

A technology of trace elements and amino acids, applied in the field of membrane separation, can solve the problems of easy saturation of the carrier, slow absorption speed, unreachable and other problems, and achieve the effect of fast hydrolysis speed, short production cycle and large power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

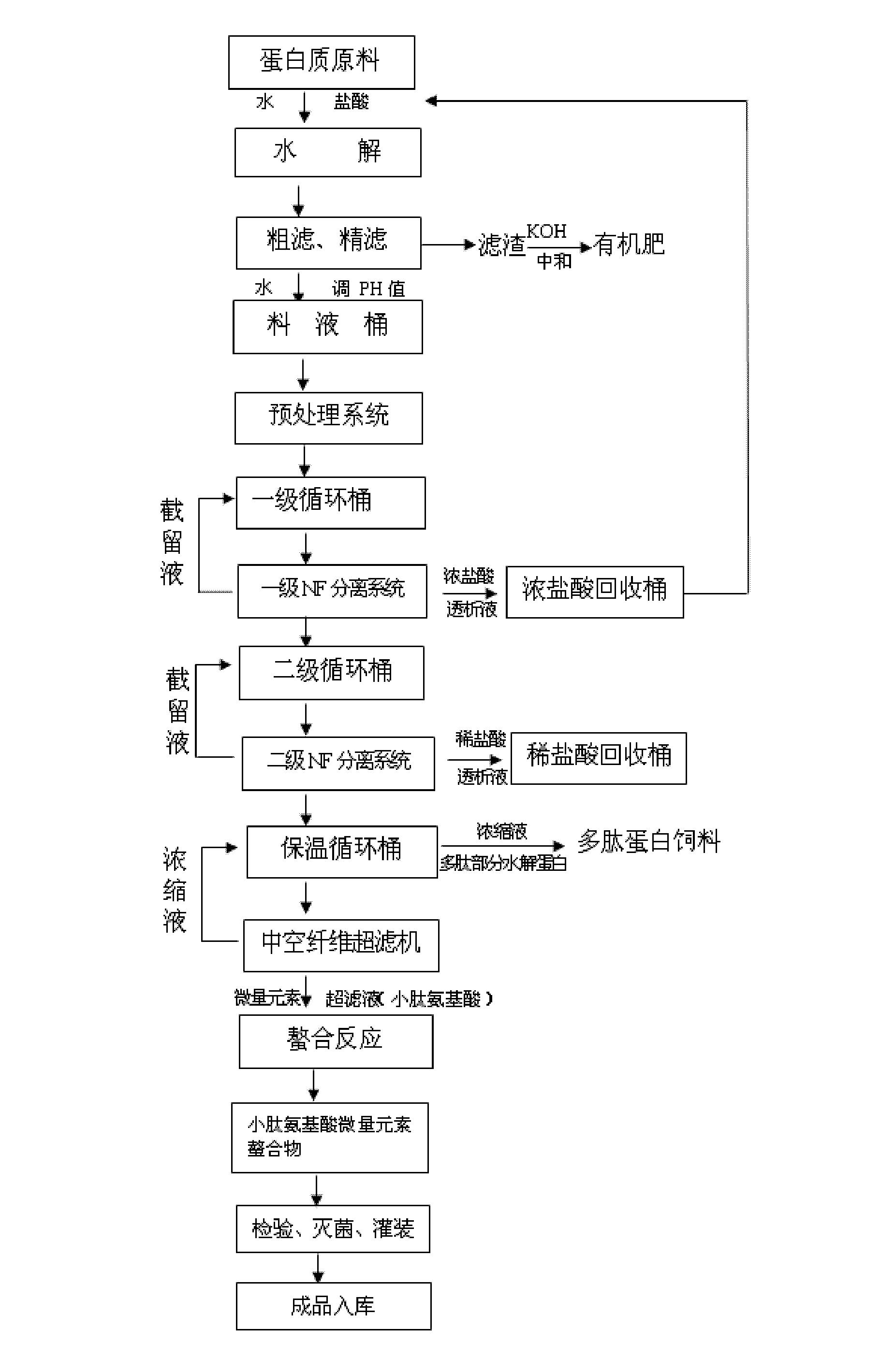

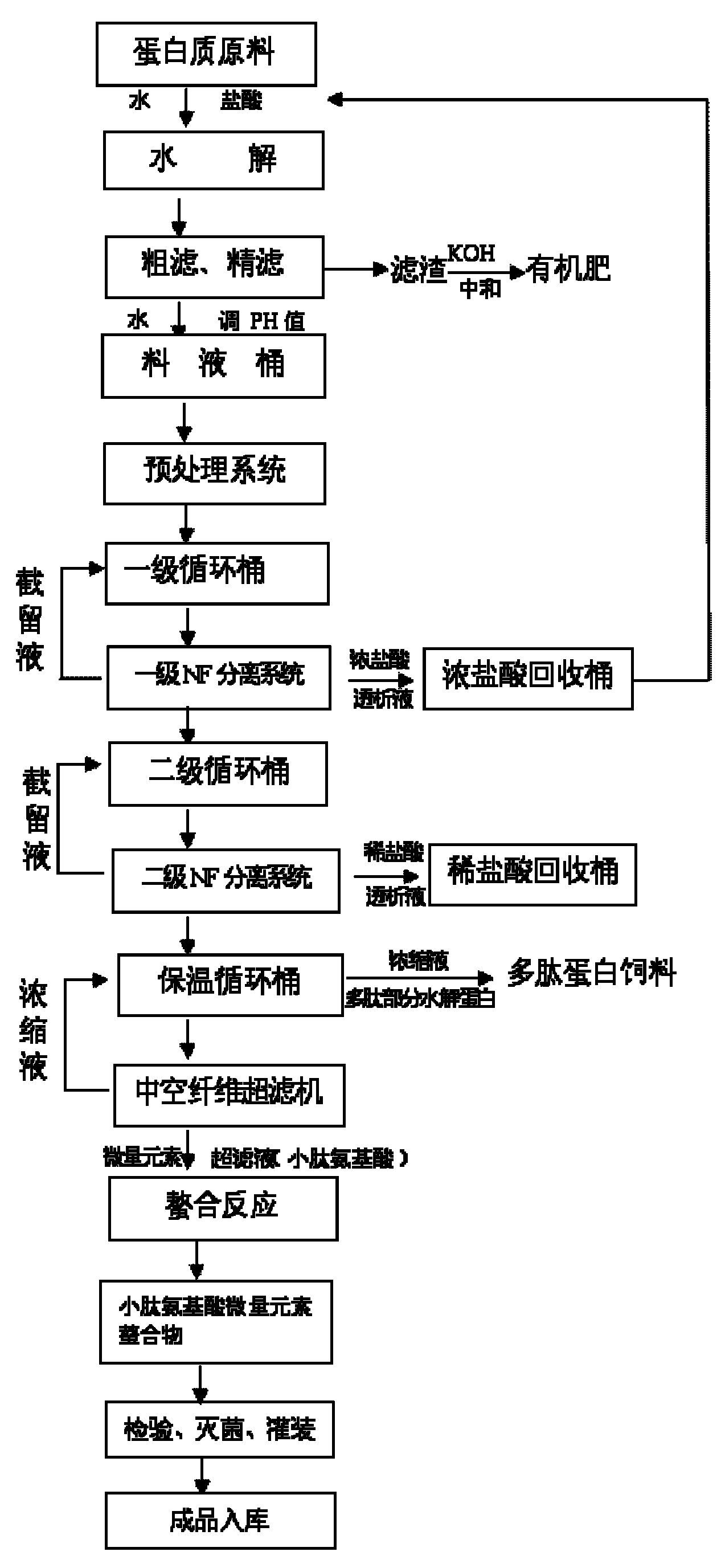

[0032] Referring to the accompanying drawings, reflecting a specific embodiment of the present invention, the equipment includes: an electric heating enamel reaction kettle equipped with a thermocouple temperature control device, a steam condensation reflux device and a frame (anchor) type enamel stirrer; equipped with a thermocouple temperature control device Electric heating stainless steel reaction kettle with frame (anchor) type agitator; acid-resistant plate and frame filter press; microfiltration compressor with 0.5μm aperture ceramic or quartz filter element; two-stage nanofiltration membrane separation device with separation aperture of molecular weight 30-70Dalton and a hollow fiber ultrafiltration unit with a separation aperture of 1000Dalton; stainless steel feed liquid barrel, circulation barrel, recovery barrel, cleaning barrel and sanitary sterilization storage tank; stainless steel feed pump, circulation pump, backwash pump and corresponding sanitary pipes road s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com