Visible-light response high energy efficiency photocatalyst prepared by composite activated carbon fiber (ACF) and application method

A photocatalytic reaction and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, energy and wastewater treatment, etc., can solve the problems of increased wastewater treatment cost, restricted application, low quantum yield, etc., and achieves repeated use. High efficiency, economical cost saving, high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0034] The preparation method of the novel composite photocatalyst is as follows:

[0035] (1) Add 0.10 mol of tetra-n-butyl titanate to 60.0 mL of absolute ethanol at room temperature, and stir for 30 minutes to obtain a uniform and transparent yellow solution A;

[0036] (2) Fully mix 56.64 mL of absolute ethanol, 40 mL of glacial acetic acid, and 14.40 mL of distilled water at room temperature, and then add 0.044 g of Sm(NO 3 ) 3 ·6H 2 O and 1.14g CH 4 N 2 Stir and dissolve the S crystals to form a solution B, which is stored in a separatory funnel for subsequent use;

[0037] (3) Under the conditions of magnetic stirring and constant temperature of 30°C, slowly add solution B dropwise to solution A to obtain a uniform and transparent sol, and age it at room temperature for 24 hours for later use;

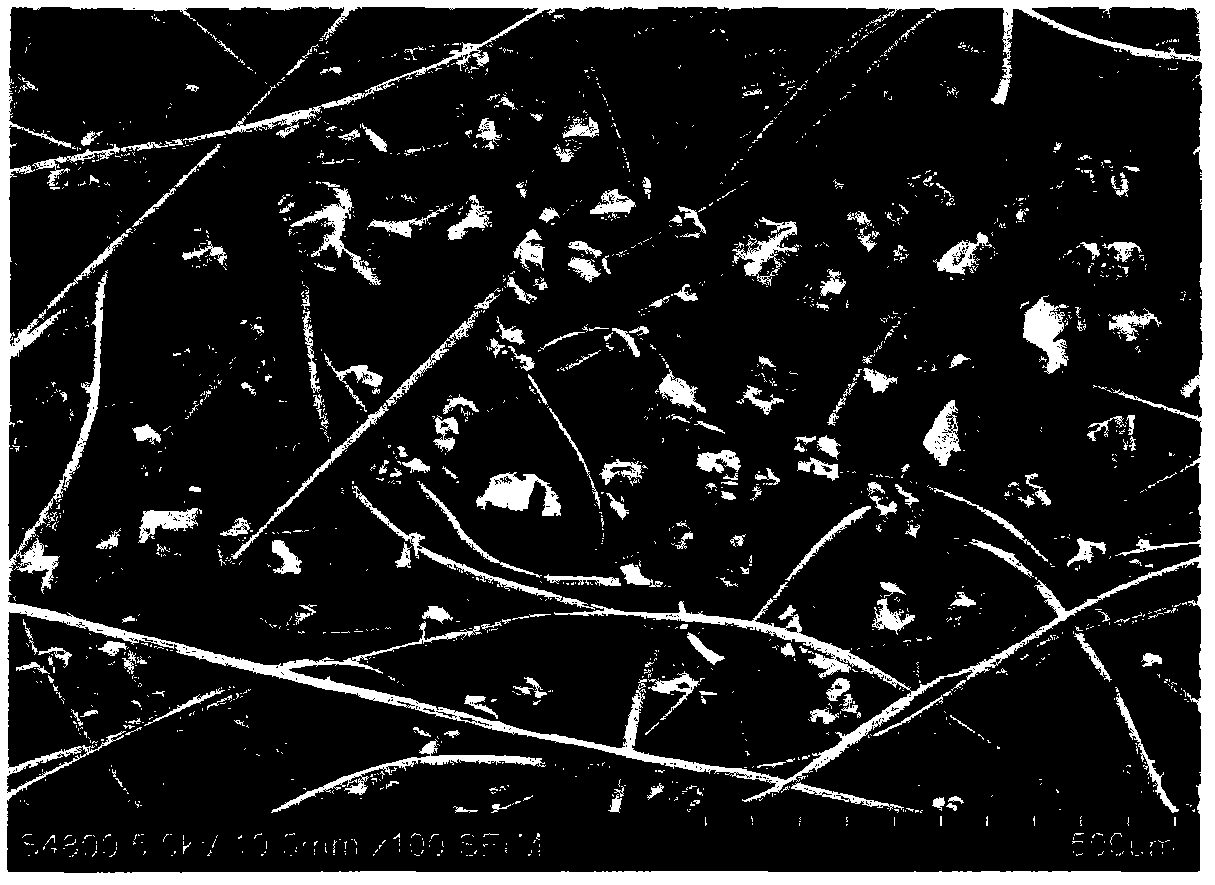

[0038] (4) Cut the activated carbon fibers activated by water vapor at 850°C for 30 minutes into long squares, immerse them in the prepared sol, and dry them in a vacuum dr...

Embodiment 1

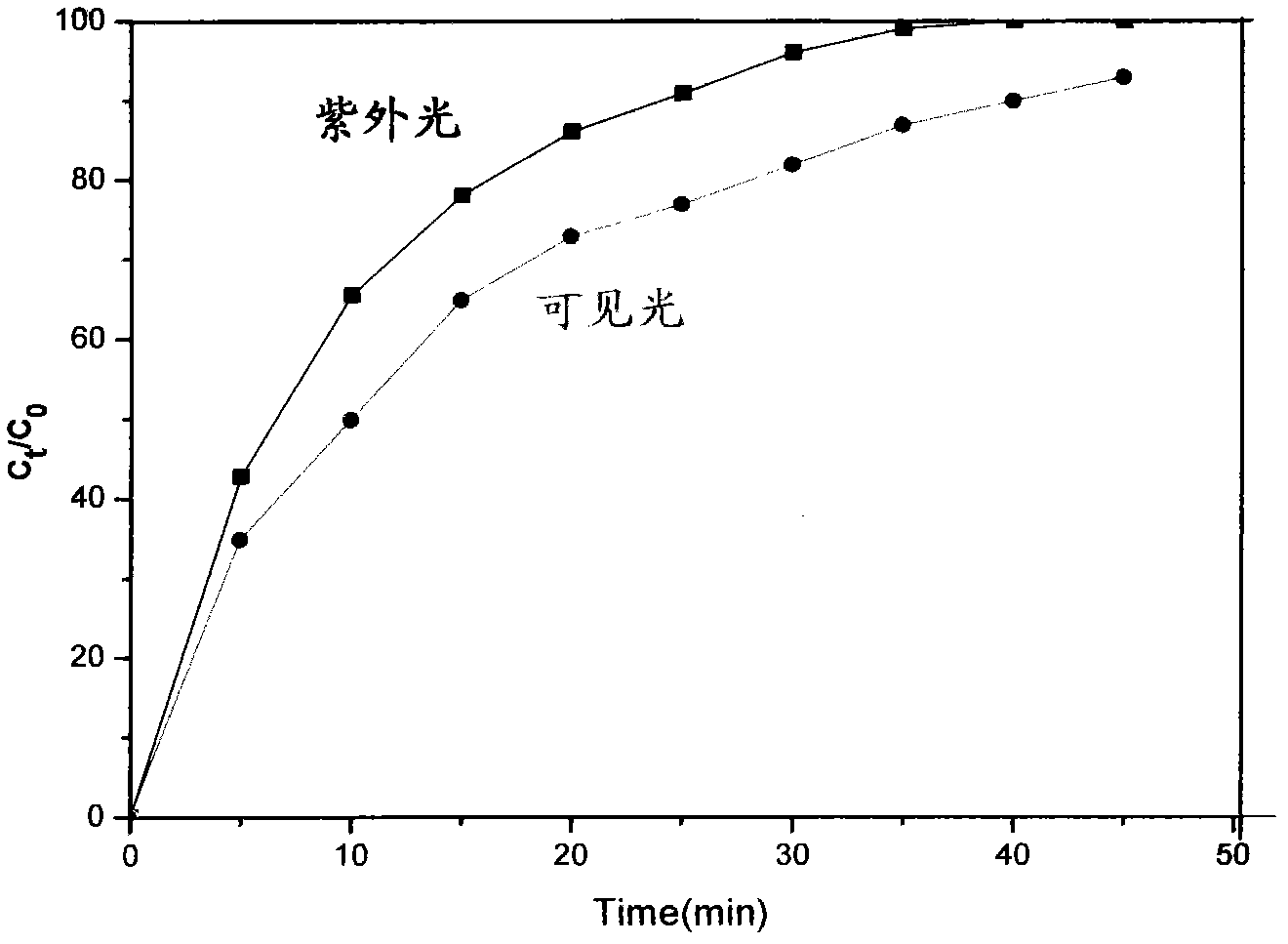

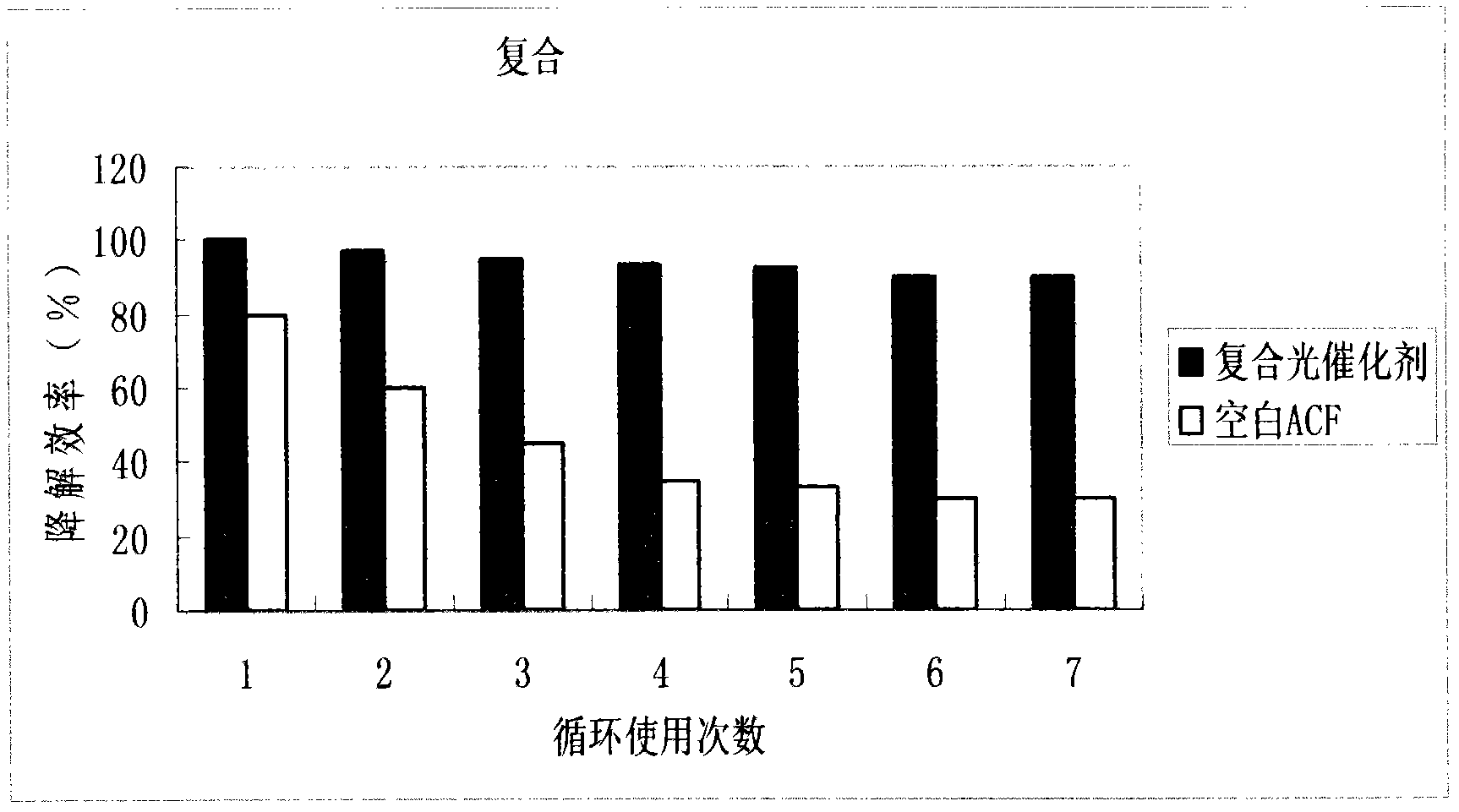

[0045] Example 1: the S 6+ 、Sm 3+ Co-doped nano TiO 2 ACF-loaded precursor (S 6+ 、Sm 3+ The doping amounts are 15.0 mol% and 0.1 mol%, respectively) were calcined in a tubular muffle furnace at 500° C. for 2 h, and nitrogen gas was continuously fed during the calcining process to obtain a high-efficiency composite photocatalyst. Get this catalyst 7.5g (4 pieces) and hang in the reaction flask of 500mL with the form of uniform symmetry, then add the Rhodamine B solution 500mL that initial concentration is 40mg / L in the reaction flask. The light source is a 500W high-pressure mercury lamp. After 8 minutes of light reaction, the decolorization rate of rhodamine B reached 100%, and it was completely degraded.

Embodiment 2

[0046] Embodiment 2: the catalyst among the example 1 is used for the methylene blue solution 500mL that initial concentration is 40mg / L. The light source is a 500W high-pressure mercury lamp. After 9 minutes of light reaction, the decolorization rate of methylene blue reached 100%, and it was completely degraded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com