Methacrylic acid-styrene-hydroxyethyl acrylate copolymer dispersant and preparation method and application thereof

A technology of hydroxyethyl acrylate and methacrylic acid, applied in carboxylate polyelectrolyte dispersant and its preparation process and application field, can solve the problems of weak adsorption, dissociation, particle re-aggregation or precipitation, etc. Low activation energy, good disintegration, and short cycle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

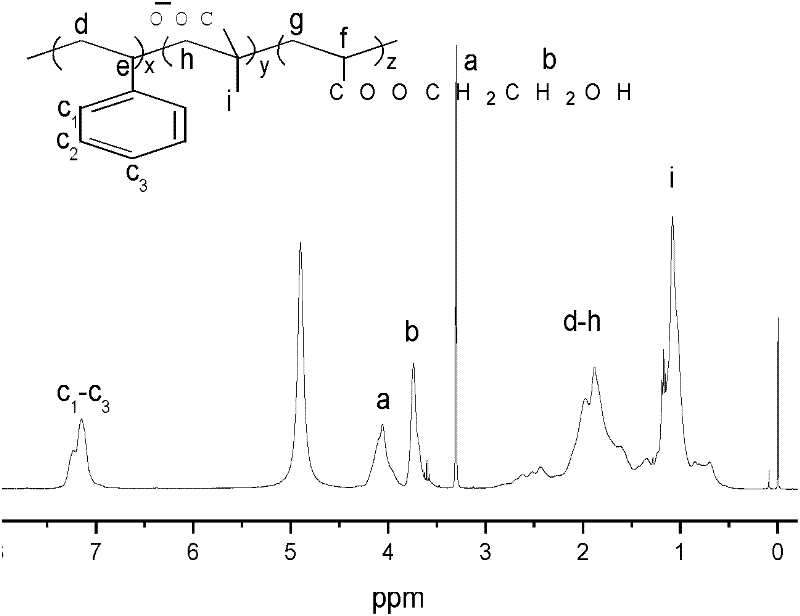

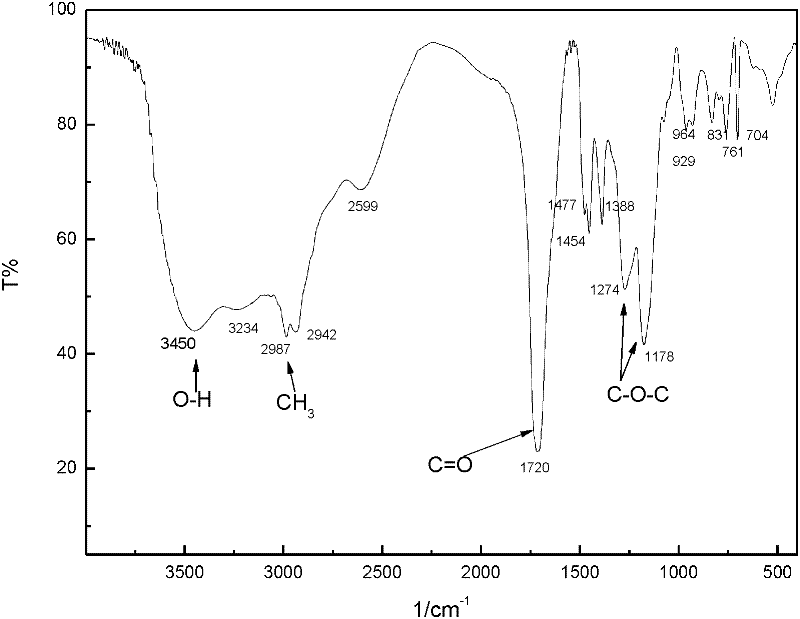

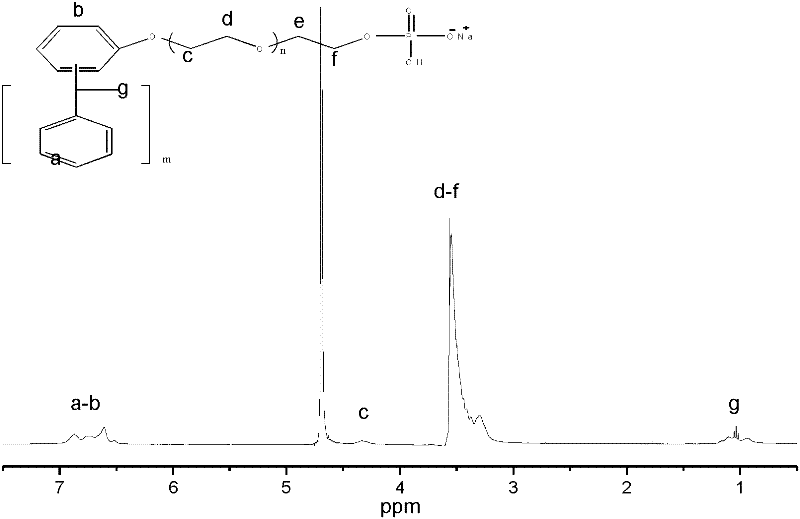

Image

Examples

Embodiment 1

[0044] 1) Preparation of dispersant

[0045] Weigh 5 parts of sodium lauryl sulfate, 1 part of thiourea, 100 parts of monomer mixture and 2 parts of rare earth complex (cerium chloride-2-isopropylthioxanthone complex) and add them to 200 parts of Fully dissolved in acetone, the composition of the monomer mixture is 10 parts styrene, 50 parts methacrylic acid and 40 parts hydroxyethyl acrylate; put the prepared solution in a light reaction tube, place it in an ultrasonic cleaner and sonicate for 10 minutes, and the ultrasonic is finished After passing nitrogen through the photoreactor tube to remove the air, then put it into the photoreactor to irradiate with an ultraviolet lamp for 60 minutes at a temperature of 10°C; add appropriate amount of water and sodium hydroxide to the resulting viscous solution to neutralize 90% of the molar amount of The carboxylic acid is then distilled off acetone to obtain a methacrylic acid-styrene-hydroxyethyl acrylate copolymer aqueous solution pr...

Embodiment 2

[0065] Weigh 1 part of sodium lauryl sulfate, 5 parts of thiourea, 100 parts of monomer mixture and 5 parts of rare earth complex (cerous chloride-anthraquinone complex) and add them to 200 parts of n-hexane to fully dissolve them. The composition of the monomer mixture is 30 parts of styrene, 50 parts of methacrylic acid and 20 parts of hydroxyethyl acrylate; the prepared solution is placed in the photoreaction tube, placed in an ultrasonic cleaner and sonicated for 10 minutes, and then sent to the photoreaction tube Pass nitrogen to remove air, then put it in the photoreactor and irradiate it with UV lamp for 30min at a temperature of 20℃; add appropriate amount of water and ammonia to the viscous solution obtained to neutralize 80% of the carboxylic acid by mole, and then distill off the normal hexane Alkane is used to obtain a methacrylic acid-styrene-hydroxyethyl acrylate copolymer aqueous solution product, which is spray-dried to obtain a white powdery solid product.

[006...

Embodiment 3

[0072] Weigh 5 parts of calcium dodecylbenzene sulfonate, 10 parts of thiourea, 100 parts of monomer mixture and 10 parts of rare earth complex (cerium chloride-benzophenone complex) and add them to 200 parts of acetone in turn Fully dissolved, the composition of the monomer mixture is 30 parts of styrene, 40 parts of methacrylic acid and 30 parts of hydroxyethyl acrylate; the prepared solution is placed in a light reaction tube, placed in an ultrasonic cleaner and sonicated for 10 minutes. Nitrogen was passed through the photoreaction tube to remove the air, and then placed in the photoreactor to irradiate with an ultraviolet lamp for 120 minutes at a temperature of 25°C; add appropriate amount of water, sodium hydroxide and diethylamine to the viscous solution obtained, and neutralize 60% by mole Then, acetone is distilled off to obtain an aqueous solution of methacrylic acid-styrene-hydroxyethyl acrylate copolymer dispersant, which is spray-dried to obtain a white powdery sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com