Preparation method of tung meal extract insecticide

An extract and pesticide technology, which is applied in the field of preparation of tung meal extract pesticides, can solve problems such as unfavorable health and sustainable development of tung oil, environmental pollution, waste of resources, etc., and achieves solutions to the lack of biological pesticides, killing The effect of high insect rate and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] This embodiment includes the following steps:

[0019] (1) After the tung meal is dried, it is pulverized by a pulverizer, passed through a 50-mesh sieve, and then heated to 100°C with ethanol with a volume fraction of 95% for reflux extraction for 3 times, and the mass of ethanol added each time is equivalent to 5 times the quality of the sieved matter, each extraction time is 2 hours, and then the extracts are combined, and the ethanol is recovered by vacuum distillation with a rotary evaporator, until all the ethanol is volatilized, and the alcohol extract extract is obtained;

[0020] (2) Add water to the alcohol extract extract obtained in step (1) and mix evenly, the quality of the added water is equivalent to 1 times the mass of the extract;

[0021] (3) Add ethyl acetate to the aqueous solution of the alcohol extract obtained in step (2), the quality of the added ethyl acetate is equivalent to 3 times the mass of the aqueous solution of the alcohol extract, stir...

Embodiment 2

[0039] The difference between this example and Example 1 is that the tung meal extract extract obtained in step (3) is mixed with surfactants, emulsifiers, and organic solvents at a mass percentage of 60:10:10:20 to obtain an emulsifiable cream type Tung meal extract insecticide.

[0040]The surfactant used in the described cream type tung meal extract insecticide is polyoxyethylene ether, of course, it can also be polyoxypropylene ether, alkyl phosphate, alkylbenzene sulfonate, bisphenol polyether, fatty acid One or more mixtures of glycerides, etc.; the emulsifier used is alkylphenol polyoxyethylene ether, of course, it can also be octylphenol polyoxyethylene ether, alkylbenzenesulfonate, stearyl polyoxyethylene ether One or more mixtures of phosphate ester, nonylphenol polyoxyethylene ether, etc.; the organic solvent used is methanol, of course, ethanol, ethyl acetate, isopropanol, isobutanol, n-hexane, toluene, etc. one or a mixture of several.

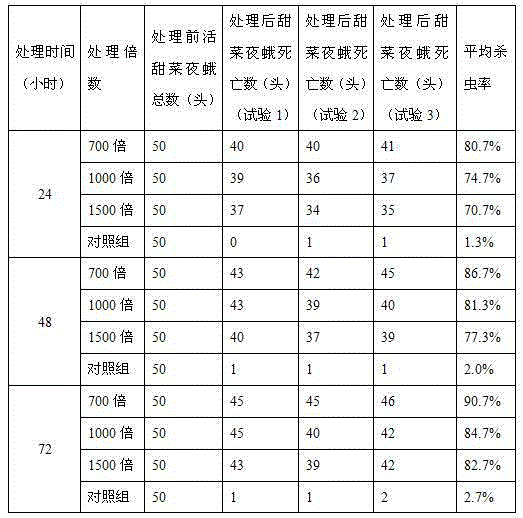

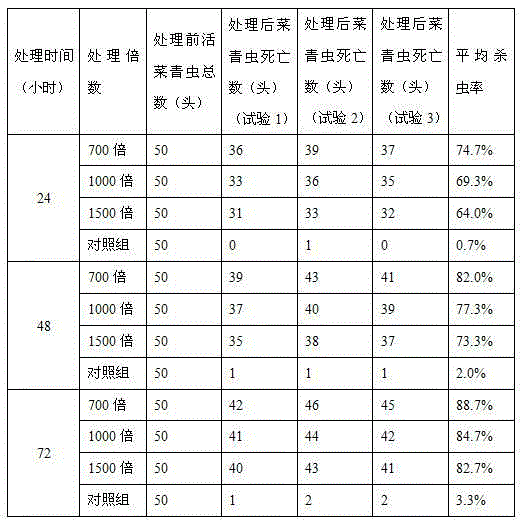

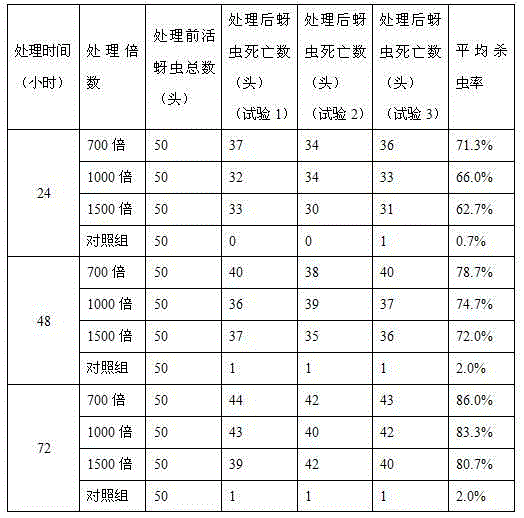

[0041] The insecticidal ...

Embodiment 3

[0058] The difference between this example and Example 1 is that after drying the tung meal extract extract obtained in step (3), it is pulverized by a pulverizer, passed through a 300-mesh sieve, and then mixed with surfactants, fillers, and pesticide assistants according to the sieved material. The agent is mixed according to the mass percentage of 50:10:25:15 to prepare a wettable powder type tung meal extract insecticide.

[0059] The used filler of described wettable powder type tung meal extract insecticide is diatomite, certainly, also can be one or more mixtures in talcum powder, bentonite and zeolite; Used surfactant is polyoxyethylene ether, Of course, it can also be one or more mixtures of polyoxypropylene ether, alkylbenzene sulfonate, alkyl phosphate, bisphenol polyether, fatty acid glyceride, etc.; the pesticide adjuvant used is lauryl sulfate Sodium, of course, can also be one or a mixture of dispersant Z, sodium lignosulfonate, etc.

[0060] The insecticidal e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com