Heat-conducting weatherable solar cell packaging material

A technology of solar cells and packaging materials, applied in circuits, photovoltaic power generation, electrical components and other directions, can solve the problems of accelerating the aging and degradation of EVA film, affecting the service life of battery components, and reducing the photoelectric conversion efficiency, so as to extend the service life, have Conducive to component heat dissipation and improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

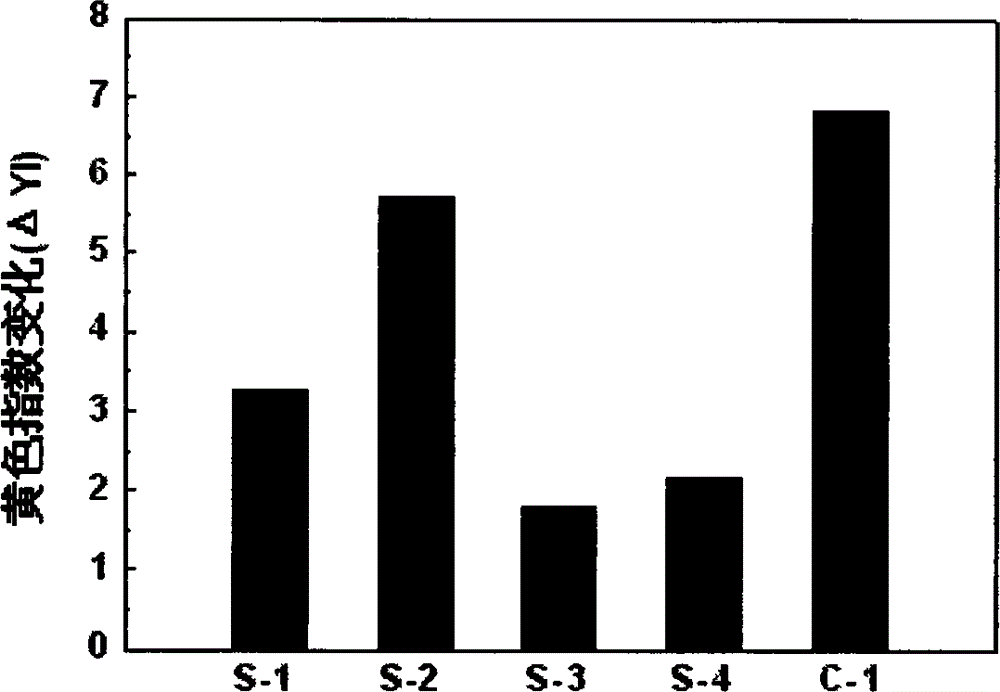

Examples

Embodiment 1

[0027] In terms of parts by mass, add 5 parts of sodium bentonite with an average size of 50 μm to 100 parts of water, stir ultrasonically until uniformly dispersed, heat to 50°C, stir and add 100 parts of cetyl trimethyl with a concentration of 0.5% dropwise The ammonium bromide aqueous solution was stirred at constant temperature for 2 hours, suction filtered, and the filtrate was washed with deionized water until the silver nitrate solution was no longer precipitated. After the filter cake was dried, it was ground into powder and passed through a 100-mesh sieve to obtain treated bentonite.

[0028] Add 10 parts of treated sodium bentonite to 100 parts of absolute ethanol, stir ultrasonically until the filler is evenly dispersed, then add dropwise a solution containing 100 parts of methyl methacrylate and 10 parts of azobisisobutyronitrile, and heat to 80°C , after stirring and reacting at constant temperature for 6 hours, suction filtration, drying, grinding into powder, and...

Embodiment 2

[0032] In terms of parts by mass, add 20 parts of sodium montmorillonite with an average size of 50 μm to 100 parts of water, stir ultrasonically until uniformly dispersed, heat to 80°C, stir and add 100 parts of hexadecyl bromide with a concentration of 3% dropwise Pyridine aqueous solution, stirred at constant temperature for 4 hours, suction filtered, washed with deionized water until the silver nitrate solution no longer precipitated, the filter cake was dried, ground into powder, passed through a 200-mesh sieve to obtain processed montmorillonite.

[0033] Add 20 parts of treated montmorillonite to 100 parts of absolute ethanol, stir ultrasonically until the filler is evenly dispersed, then add dropwise a solution containing 200 parts of butyl acrylate and 20 parts of azobisisobutyronitrile, heat to 90°C, and keep the temperature constant After stirring and reacting for 8 hours, suction filter, dry, grind into powder, and pass through a 200-mesh sieve to obtain butyl acryl...

Embodiment 3

[0037] In terms of parts by mass, add 30 parts of sodium bentonite with an average size of 100 μm to 100 parts of water, stir ultrasonically until uniformly dispersed, heat to 90°C, stir and add 100 parts of octadecyltrimethyl chloride with a concentration of 5% dropwise The ammonium chloride aqueous solution was stirred at constant temperature for 6 hours, suction filtered, and the filtrate was washed with deionized water until the silver nitrate solution was no longer precipitated. After the filter cake was dried, it was ground into powder and passed through a 200-mesh sieve to obtain treated bentonite.

[0038] Add 5 parts of treated bentonite to 100 parts of absolute ethanol, stir ultrasonically until the filler is evenly dispersed, then add dropwise a solution containing 50 parts of butyl methacrylate and 1 part of azobisisoheptanonitrile, heat to 70°C, and keep the temperature constant After stirring and reacting for 2 hours, suction filter, dry, grind into powder, and pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com