Preparation method of water-borne long-chain acrylate separant

A technology of acrylates and release agents, which is applied in the field of preparation of water-based long-chain acrylate release agents, can solve the problems that the application field has not been fully developed and the theory of miniemulsion polymerization starts late, and achieves the elimination of aging effects and good Isolation effect, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

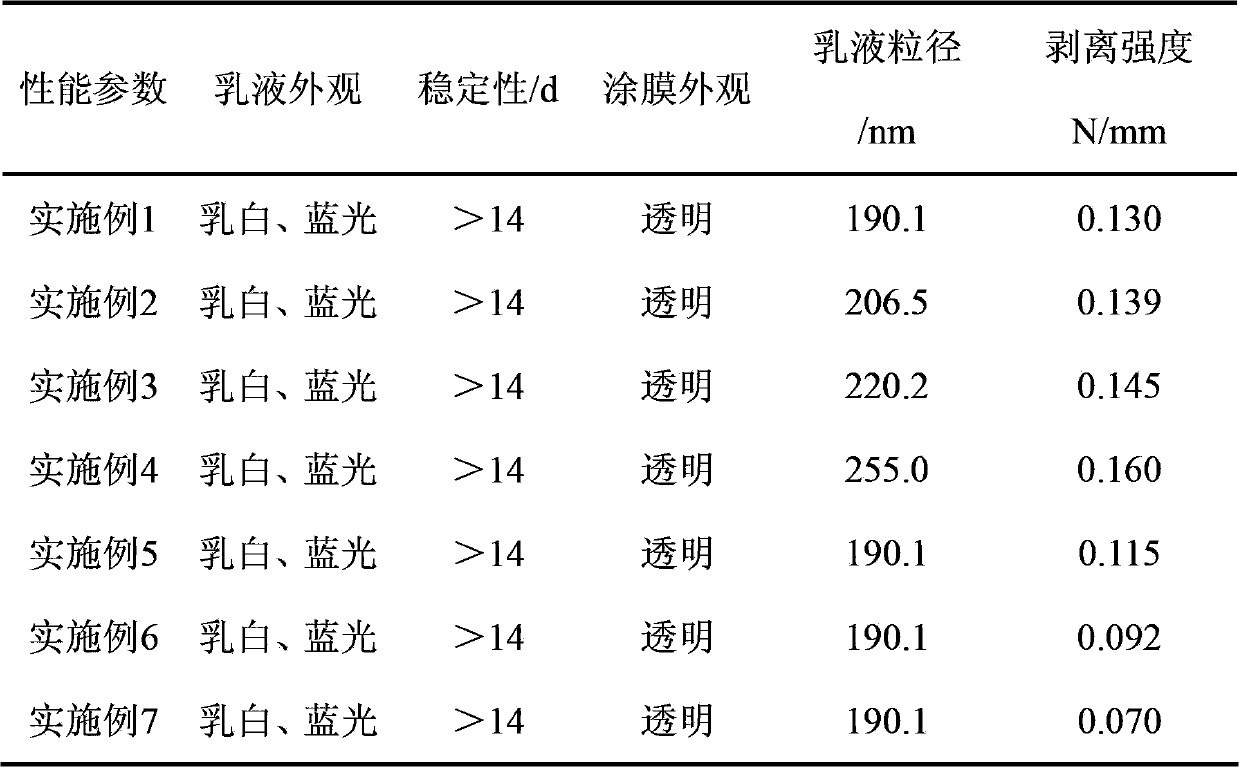

Examples

Embodiment 1

[0031] (1) Weigh raw materials according to the following weight percentages: deionized water 50%, lauryl methacrylate 9.8%, isobornyl acrylate 9.8%, methyl methacrylate 8.2%, butyl acrylate 8.2%, acrylonitrile 5.9% , acrylic acid 5.1%, sodium lauryl sulfate 1%, sodium bicarbonate 1%, ammonium persulfate 0.5%, sodium persulfate 0.5%;

[0032] (2) Add deionized water, lauryl methacrylate, isobornyl acrylate, methyl methacrylate, butyl acrylate, acrylonitrile, acrylic acid, sodium lauryl sulfate, and sodium bicarbonate into a beaker at 50°C Stir for 20min under the condition to prepare the pre-emulsion A;

[0033] (3) Place the pre-emulsion A in an ultrasonic cell pulverizer and emulsify it in an ice-water bath for 5 minutes to prepare the mini-emulsion B;

[0034] (4) Pour the above-mentioned miniemulsion B into a four-necked flask equipped with a stirrer, a condenser, a nitrogen passage, and a thermometer. After raising the temperature to 75°C, add ammonium persulfate and sod...

Embodiment 2

[0038] (1) Weigh raw materials according to the following weight percentages: 50% deionized water, 9.8% lauryl methacrylate, 9.8% octadecyl methacrylate, 8.2% methyl methacrylate, 8.2% butyl acrylate, Styrene 5.9%, acrylic acid 5.1%, sodium dodecyl sulfonate 1%, sodium bicarbonate 1%, sodium persulfate 0.3%, ammonium persulfate 0.5%, potassium persulfate 0.4%;

[0039] (2) Add deionized water, lauryl methacrylate, octadecyl methacrylate, methyl methacrylate, butyl acrylate, styrene, acrylic acid, sodium lauryl sulfonate, carbonic acid Sodium hydrogen, stirred at 50°C for 30 minutes to prepare pre-emulsion A;

[0040] (3) Place pre-emulsion A in an ultrasonic cell pulverizer and emulsify for 5 minutes in an ice-water bath to prepare fine emulsion B;

[0041] (4) Pour the above microemulsion B into a four-neck flask equipped with a stirrer, a condenser, a nitrogen passage, and a thermometer. After heating up to 80°C, add sodium persulfate, ammonium persulfate and potassium pers...

Embodiment 3

[0044] (1) Weigh raw materials according to the following weight percentages: 60% deionized water, 11% lauryl methacrylate, 12.5% octadecyl acrylate, 8.6% butyl acrylate, 5.9% styrene, 1.1% acrylic acid, ten Hexaalkyl sodium sulfate 0.3%, sodium bicarbonate 0.3%, ammonium persulfate 0.3%;

[0045] (2) Add in a beaker, deionized water, lauryl methacrylate, stearyl acrylate, butyl acrylate, styrene, acrylic acid, sodium cetyl sulfate, sodium bicarbonate, at 45 ° C Stir for 35min to prepare pre-emulsion A;

[0046] (3) Place the pre-emulsion A in an ultrasonic cell pulverizer and emulsify it in an ice-water bath for 5 minutes to prepare the mini-emulsion B;

[0047] (4) Pour the above-mentioned miniemulsion B into a four-necked flask equipped with a stirrer, a condenser, a nitrogen passage, and a thermometer. After heating up to 85°C, add ammonium persulfate and keep it warm for 7 hours to obtain a long-chain acrylate release agent. .

[0048] The method for testing the rele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com