Catalyst for growing three-dimensional carbon nanotube/grapheme composite material and preparation method of catalyst

A carbon nanotube and composite material technology is applied in the field of preparation of catalysts for the growth of three-dimensional carbon nanotube/graphene composite materials, and can solve problems such as unfavorable effective specific surface area and energy storage density, inability to fully and effectively exert characteristics, and inability to react. Go ahead and other problems to avoid uncontrollable temperature, easy control and realization, and prevent agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

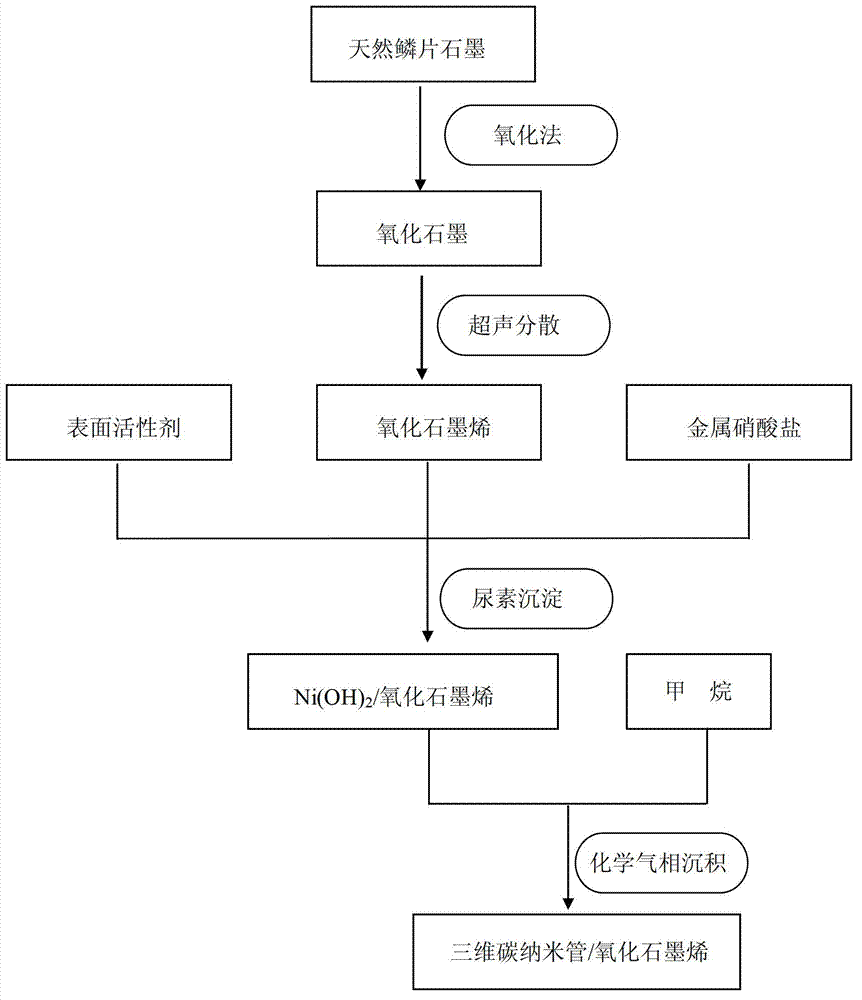

[0038] The specific steps of the catalyst preparation method for the growth of the three-dimensional carbon nanotube / graphene composite material of the present invention are:

[0039] 1) Dissolve the surfactant in deionized water, then add the graphene oxide suspension to the above solution, and disperse under ultrasonic conditions for 20-60 minutes to fully mix the surfactant and graphene oxide;

[0040] Wherein, the mass ratio of surfactant to nickel nitrate is 1-4, preferably 1.25; the surfactant is one of sodium lauryl sulfate and mercaptoacetic acid;

[0041] 2) Gradually add the nickel nitrate solution into the solution obtained in step 1) under vigorous stirring; wherein, the dropping rate of the nickel nitrate solution is 0.3-2ml / min (10mg / ml); the stirring speed is 250-325r / min; The mass ratio of nickel and graphene oxide is 0.5-6, preferably 4;

[0042] 3) Add urea to the solution obtained in step 2), and heat the mixed solution to 85-95°C (after heating urea in wat...

Embodiment 1

[0048] Assemble a 500mL reaction bottle in an ice-water bath, add 120ml of concentrated sulfuric acid, add a solid mixture of 5g of graphite powder and 2.5g of sodium nitrate under stirring, stir in an ice-water bath for 30min, then add 15g of potassium permanganate in portions to control the reaction The temperature does not exceed 20°C, stir and react for a period of time, then raise the temperature to about 35°C, continue to stir for 30 minutes, then slowly add a certain amount of deionized water, the temperature rises to 98°C, after stirring for 20 minutes, further dilute with water, and add 50ml of hydrogen peroxide (30%) to reduce the residual oxidant, so that the solution turns bright yellow; filter while hot, and wash with 5% HCl solution and deionized water until no sulfate group is detected in the filtrate; finally put the filter cake in a 60°C Fully dry in a vacuum drying oven; then 200mg graphene oxide is ultrasonically dispersed in 300ml deionized water for 40min t...

Embodiment 2-14

[0050] Compared with Example 1, only the catalyst component content, or the type of surfactant used, or the nickel nitrate solution drop rate, or the stirring speed are different, and the other processes are the same as in Example 1, and each finished catalyst is obtained. The catalyst composition of embodiment 2 to embodiment 14 and its used dropping speed and stirring speed are shown in table 1.

[0051] Table 1 Catalyst Composition Table

[0052]

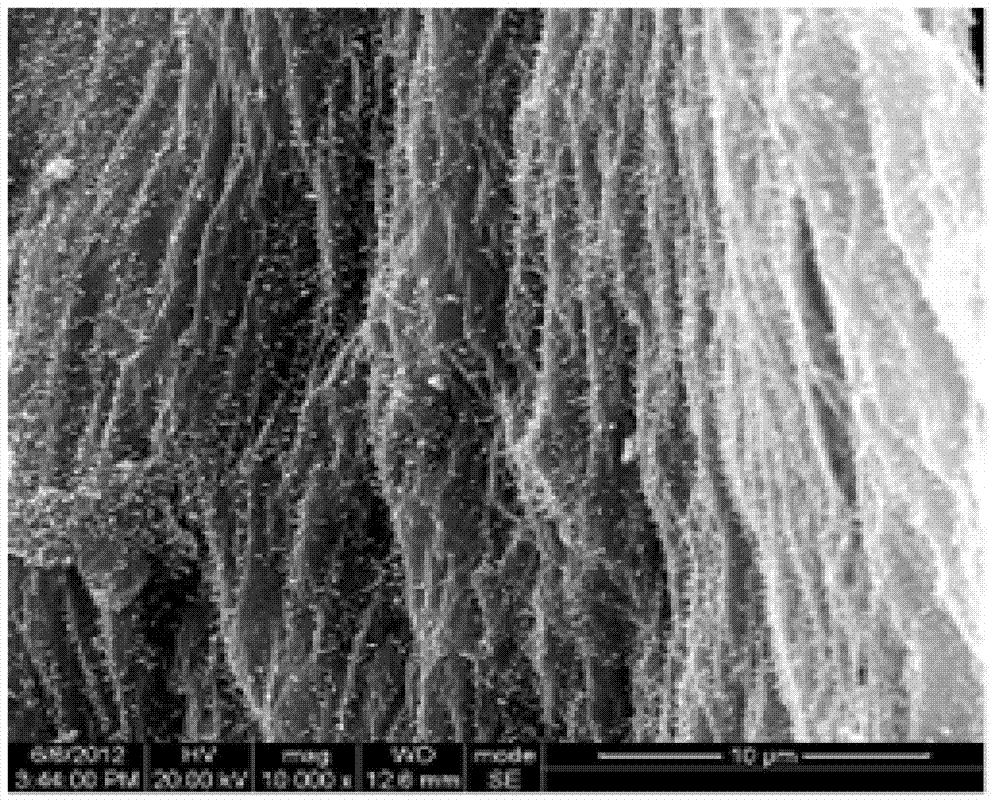

[0053] Place the catalyst obtained in Examples 1-11 in the middle of the heating zone of the horizontal reaction furnace, raise the temperature to a reaction temperature of 850°C at a rate of 10°C / min under a nitrogen atmosphere, switch to methane (volume flow rate 100mL / min), react for 5 minutes, and close methane, and cooled to room temperature in a nitrogen atmosphere to prepare a three-dimensional carbon nanotube / graphene composite material sample.

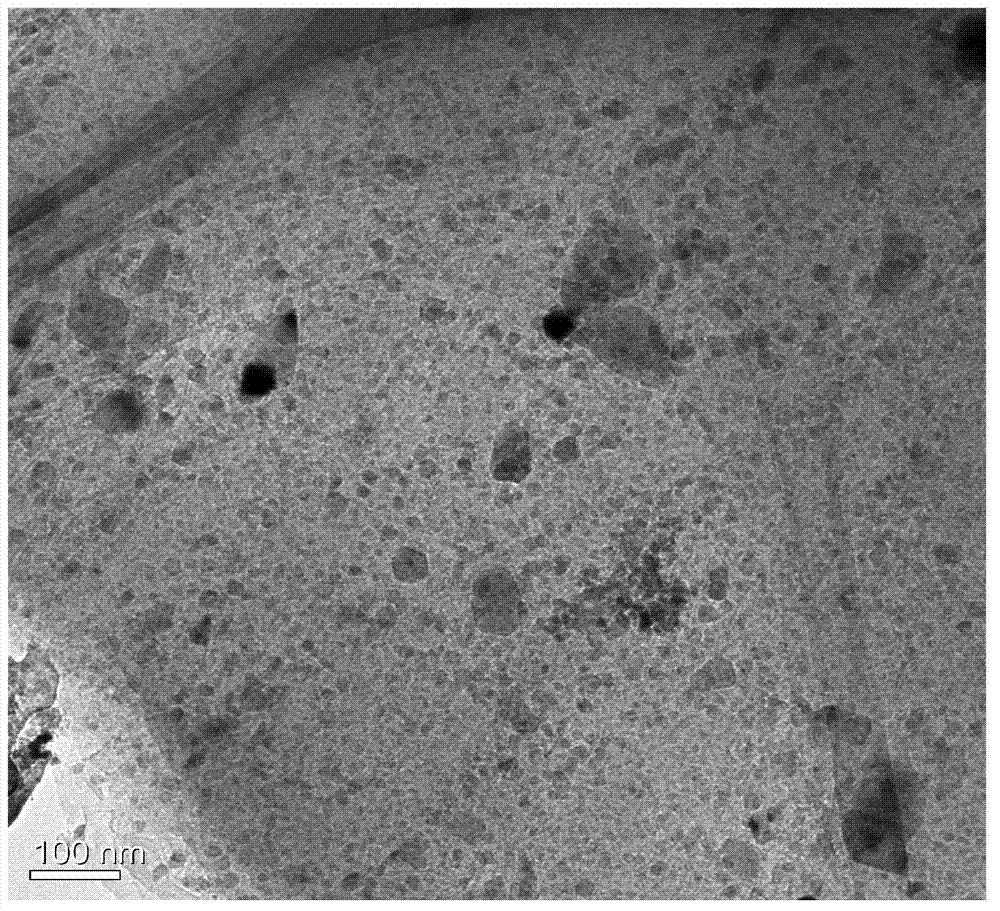

[0054] The scanning electron micrograph of the three-dimensional carbon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com