Graphene oxide/silver phosphate/P25 composite material and preparation method thereof

A composite material and silver phosphate technology, applied in chemical instruments and methods, botanical equipment and methods, chemical/physical processes, etc., can solve the problem of large size of silver phosphate materials, reduced recombination rate of photogenerated carriers, and low quantum efficiency and other problems, to achieve the effect of widening the response range of visible light, improving the utilization rate of sunlight, and simple and easy process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

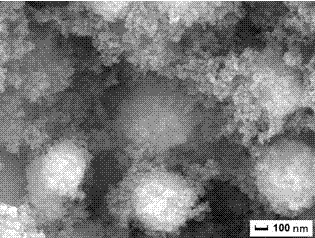

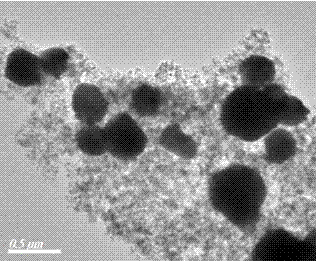

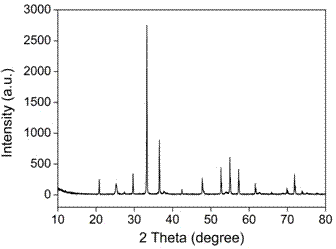

Image

Examples

Embodiment 1

[0025] Disperse 20 mg of graphene oxide in 50 ml of deionized water and sonicate for 5 hours to obtain a graphene oxide dispersion, weigh 1.529 g of silver nitrate and 300 mg of P25 and dissolve them in 50 ml of deionized water for 30 minutes to obtain a mixed solution A; Add the mixed solution A dropwise to the above-mentioned graphene oxide dispersion under magnetic stirring, and continue stirring for half an hour to obtain the mixed precursor solution B; weigh 0.426 g Na 2 HPO 4 The solid was dissolved in 20 ml of deionized water to obtain a disodium hydrogen phosphate solution, and the prepared disodium hydrogen phosphate solution was added dropwise to the mixed precursor solution B under agitation until gray-green turbidity appeared in the reaction system, and the addition was completed After that, the mixed solution was continuously stirred for 30 minutes and left to stand for aging. After the product was centrifuged, it was repeatedly washed with absolute ethanol and de...

Embodiment 2-12

[0028] The difference between the following examples and Example 1 is that the quality of graphene oxide used, the quality of P25, the type of phosphate and the quality are different, as shown in Table 1, and the rest are the same as described in Example 1.

[0029] Table 1

[0030] Example Graphene Oxide Quality P25 Quality Phosphate type Phosphate mass Example 2 50mg 300mg Na 2 HPO 4 0.426 g Example 3 20mg 400mg Na 2 HPO 4 0.426 g Example 4 50mg 400mg Na 2 HPO 4 0.426 g Example 5 20mg 600mg Na 2 HPO 4 0.426 g Example 6 50mg 600mg Na 2 HPO 4 0.426 g Example 7 20mg 300mg NaH 2 PO 4 0.36 g Example 8 50mg 300mg NaH 2 PO 4 0.36 g Example 9 20mg 400mg NaH 2 PO 4 0.36 g Example 10 50mg 400mg NaH 2 PO 4 0.36 g Example 11 20mg 600mg NaH 2 PO 4 0.36 g Example 12 50mg 600mg NaH 2 PO 4 0.36 g Example 13 ...

Embodiment 19

[0032] The composite materials prepared in Examples 1-18 were co-cultured with Escherichia coli, Staphylococcus aureus, Bacillus pumilus and Pseudomonas aeruginosa respectively, and the plate method, minimum inhibitory concentration and minimum bactericidal concentration tests were carried out. The test method was operated in accordance with the "Technical Specifications for Disinfection" of the Ministry of Health of the People's Republic of China, and the strains used were provided by the School of Pharmacy, Jiangsu University.

[0033] Table 2

[0034]

[0035] The results of the plate method inhibition zone test are shown in Table 2. The industry standard of the People's Republic of China stipulates that when the diameter of the compound inhibition zone is less than 7 milliliters, it can be considered as having no antibacterial effect; when the inhibition zone is between 7-10 mm, it is weak. Antibacterial activity; the antibacterial activity is better when the diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com