Preparation method for inverse organic solar battery preparation method

A solar cell and organic technology, applied in circuits, electrolytic coatings, electrophoretic plating, etc., can solve the problems of inability to realize flexible device production, inability to effectively control costs, and large film size restrictions, and achieve unlimited film size , Low treatment temperature, low preparation temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

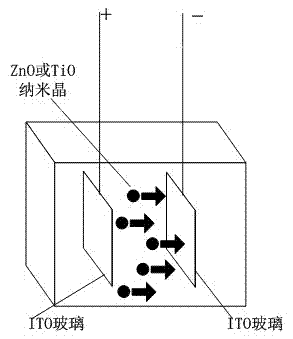

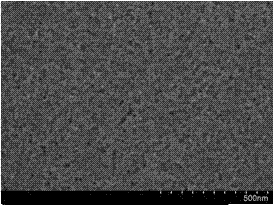

[0026] Synthesize ZnO nanocrystals by wet chemical method; dissolve ZnO nanocrystals in a solution with a volume ratio of methanol: chloroform of 4:1, and prepare a mixed solution of ZnO nanocrystals methanol and chloroform with a concentration of 0.01mol / L; use electrophoretic deposition method , the electrophoretic device such as figure 2 As shown, in the mixed solution of methanol and chloroform of nanocrystals, ITO glass with the same size is used as the electrode. Voltage 5V, time 3 minutes, deposit ZnO nanocrystals on the ITO glass substrate to obtain a ZnO nanocrystal film with a thickness of 45nm; anneal the ZnO nanocrystal film at 200oC for 60 minutes in an air atmosphere to form a uniform and high-transmittance film. rate of ZnO nanocrystalline films (eg image 3 , Figure 4 shown), and then spin-coat a layer of P3HT:PCBM organic photosensitive layer on the ZnO film, and then vapor-deposit 5nm-thick molybdenum oxide and 100nm-thick aluminum electrode in sequence t...

Embodiment 2

[0031] Synthesize ZnO nanocrystals by wet chemical method; dissolve ZnO nanocrystals in a solution with a volume ratio of methanol: chloroform of 4:1, and prepare a mixed solution of ZnO nanocrystals methanol and chloroform with a concentration of 0.001mol / L; use electrophoretic deposition method , voltage 8V, time 3 minutes, deposit ZnO nanocrystals on the ITO / polyethylene naphthalate substrate to obtain a ZnO nanocrystal film with a thickness of 60nm; place the ZnO nanocrystal film at 100oC in a pure argon atmosphere Anneal for 60 minutes to form a ZnO nanocrystalline film with uniform high transmittance, then spin-coat a layer of P3HT:PCBM organic photosensitive layer on the ZnO film, and then vapor-deposit 5nm-thick molybdenum oxide and 100nm-thick aluminum electrode in sequence. Inverted organic solar cells. It has the following characteristics:

[0032] (1) The short-circuit current is relatively large, reaching 7.26mA / cm 2 ;

[0033] (2) Open circuit voltage (0.64V) ...

Embodiment 3

[0036] Synthesis of TiO by wet chemistry 2 nanocrystalline; the TiO 2 The nanocrystals were dissolved in a methanol:chloroform solution with a volume ratio of 4:1 to prepare TiO with a concentration of 0.5mol / L 2 Nanocrystalline methanol chloroform mixed solution; use electrophoretic deposition method, voltage 10V, time 3 minutes, deposit TiO on the ITO glass substrate 2 Nanocrystalline, obtained TiO with a thickness of 66nm 2 Nanocrystalline film; the TiO 2The nanocrystalline film was annealed at 250oC for 60 minutes under pure nitrogen atmosphere to form a uniform and high transmittance TiO 2 nanocrystalline film, then the TiO 2 A layer of P3HT: PCBM organic photosensitive layer was spin-coated on the film, and then 5nm-thick molybdenum oxide and 100nm-thick aluminum electrode were sequentially vapor-deposited to prepare an inverted organic solar cell. It has the following characteristics:

[0037] (1) The short-circuit current is relatively large, reaching 8.02mA / cm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com