Method for preparing powder polycarboxylic acid superplasticizer

A technology of superplasticizer and polycarboxylic acid, which is applied in the field of preparing powdery high-performance superplasticizer for mortar and concrete, can solve the problem that powdery polycarboxylate superplasticizer has not been solved, and can reduce transportation costs. Cost and packaging costs, low bleed air, and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

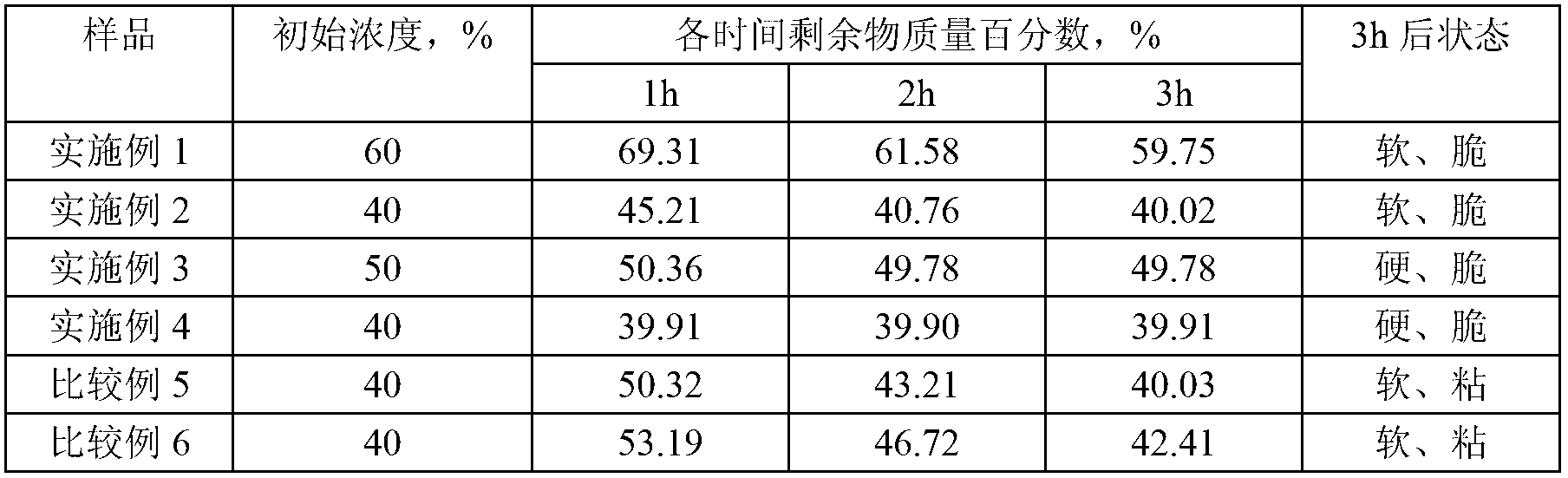

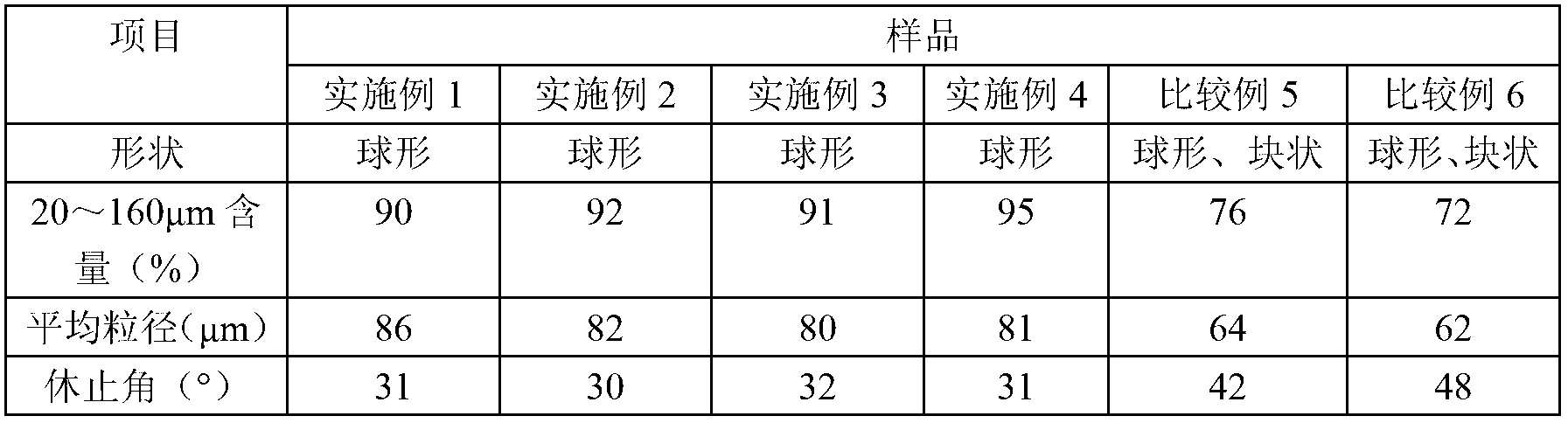

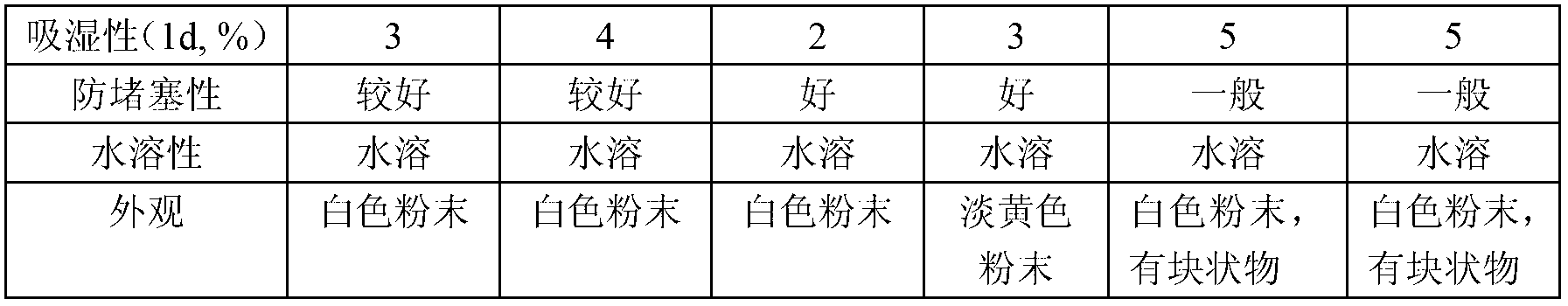

[0025] Add 28.07g of acrylic macromonomer with m=1, n=9, propylene oxide and ethylene oxide random copolymerization of isobutylene alcohol open ether with m=90, n=22 into the four-necked flask equipped with stirring 264.55g of quasi-macromonomer and 185g of distilled water were fully stirred, and the temperature was raised to 80°C. Dissolve 14.4 g of acrylic acid and 31.6 g of sodium methacrylate in 21.56 g of distilled water to prepare solution A, and dissolve 1.14 g of ammonium persulfate in 20.0 g of distilled water to prepare solution B. At 80°C, solutions A and B were added dropwise for 2 hours respectively, and then kept at constant temperature for 1 hour. After the heat preservation was completed, the temperature was lowered to 45°C, and 10.0 g of 60% NaOH solution was added to neutralize to pH = 7 to prepare a polycarboxylate superplasticizer sample 1 with a concentration of 60%. The neutralized polycarboxylate superplasticizer solution is spray-dried to obtain the po...

Embodiment 2

[0027]Add m=95, n=5 propylene oxide and ethylene oxide block copolymerization (in which ethylene oxide and propylene oxide are arranged in 40-5-45 blocks) isopentyl to a stirring four-necked flask Mix 700.0g of enol-terminated ether macromonomer and 500.0g of distilled water thoroughly, raise the temperature to 20°C, and mix 58.1g of fumaric acid, 5.0g of thioglycolic acid, and 12.6g of 30% hydrogen peroxide in sequence every 5 to 10 minutes. was added into a four-neck flask. Dissolve 8.71 g of ascorbic acid in 88.6 g of distilled water to prepare an aqueous solution. Within 5-10 minutes of adding hydrogen peroxide, add ascorbic acid aqueous solution dropwise at 20°C for 3 hours, and then keep the temperature for 3 hours. After the heat preservation was completed, 20.0 g of 40% NaOH solution and 5 g of triethanolamine were added directly to neutralize to pH=7.5 to prepare a polycarboxylate superplasticizer sample 2 with a concentration of 40%. The neutralized polycarboxylate...

Embodiment 3

[0029] Add 260.5g of propylene oxide and ethylene oxide random copolymerization of prenol-terminated ether macromonomers with m=n=25 to a four-necked flask equipped with stirring, and 250g of distilled water, stir well, and heat up to 60°C , 35.55g of acrylamide and 3.0g of n-dodecyl mercaptan were added to the four-necked flask at one time every 5~10min in order, and 3.6g of ammonium persulfate was dissolved in 52.7g of distilled water to make a uniform aqueous solution. was added into a four-neck flask. Incubate at constant temperature for 4 hours at 60°C. After the heat preservation was completed, the temperature was lowered to 45°C, 5.0 g of 50% NaOH solution and 2 g of diethanolamine were added, neutralized to pH=8.0, and a polycarboxylate superplasticizer sample 3 with a concentration of 50% was prepared. The neutralized polycarboxylate superplasticizer solution is spray-dried to obtain a polycarboxylate superplasticizer powder product. The spray-drying parameters are: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com