Method for preparing cation exchange membrane with monovalent preferential separation function

A cation exchange membrane, functional technology, applied in the field of ion exchange membrane, can solve the problems of limited types of modified materials, limited separation performance life, complicated preparation process, etc., to achieve simple membrane preparation process, excellent membrane selection and separation performance , the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

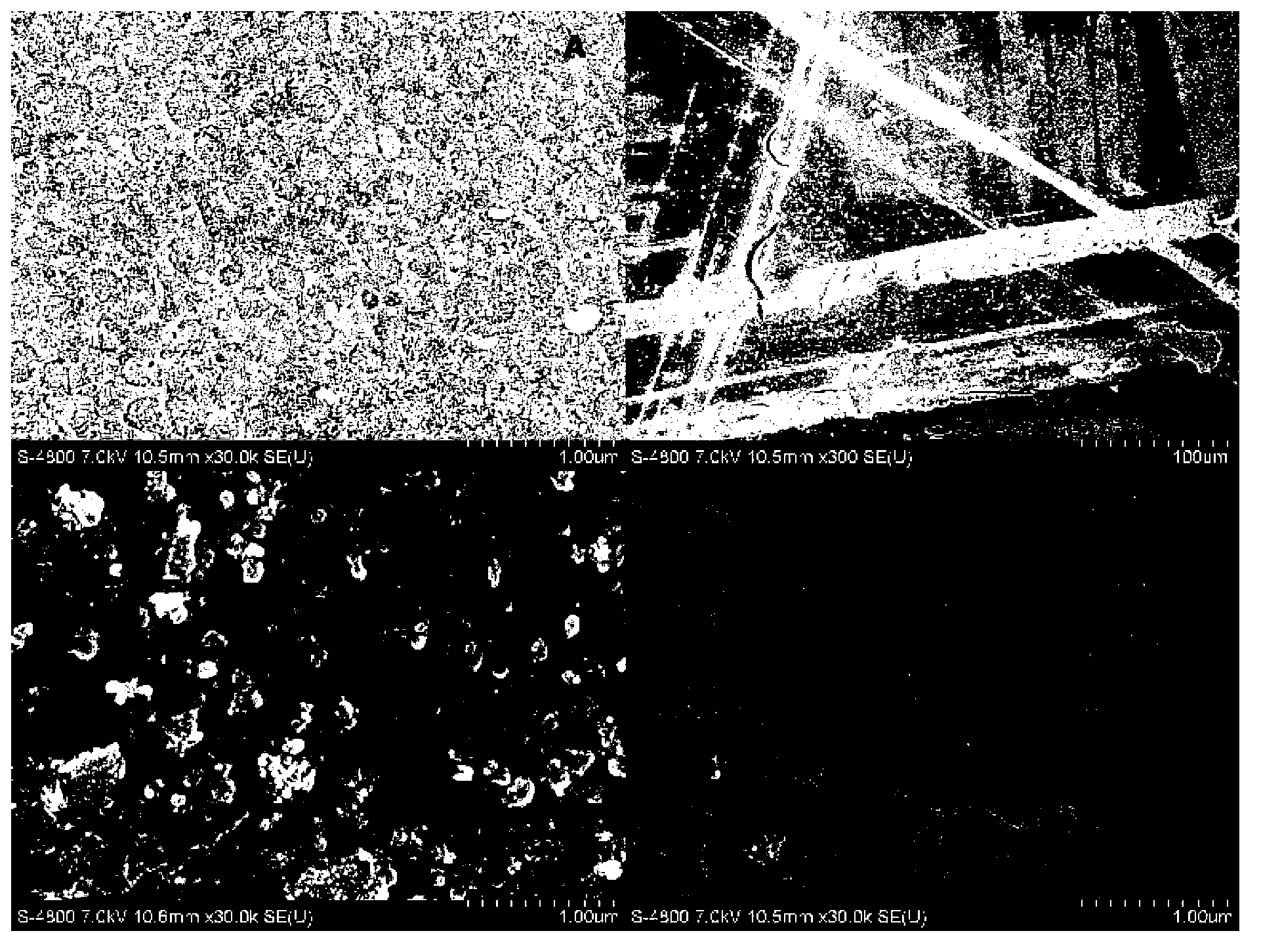

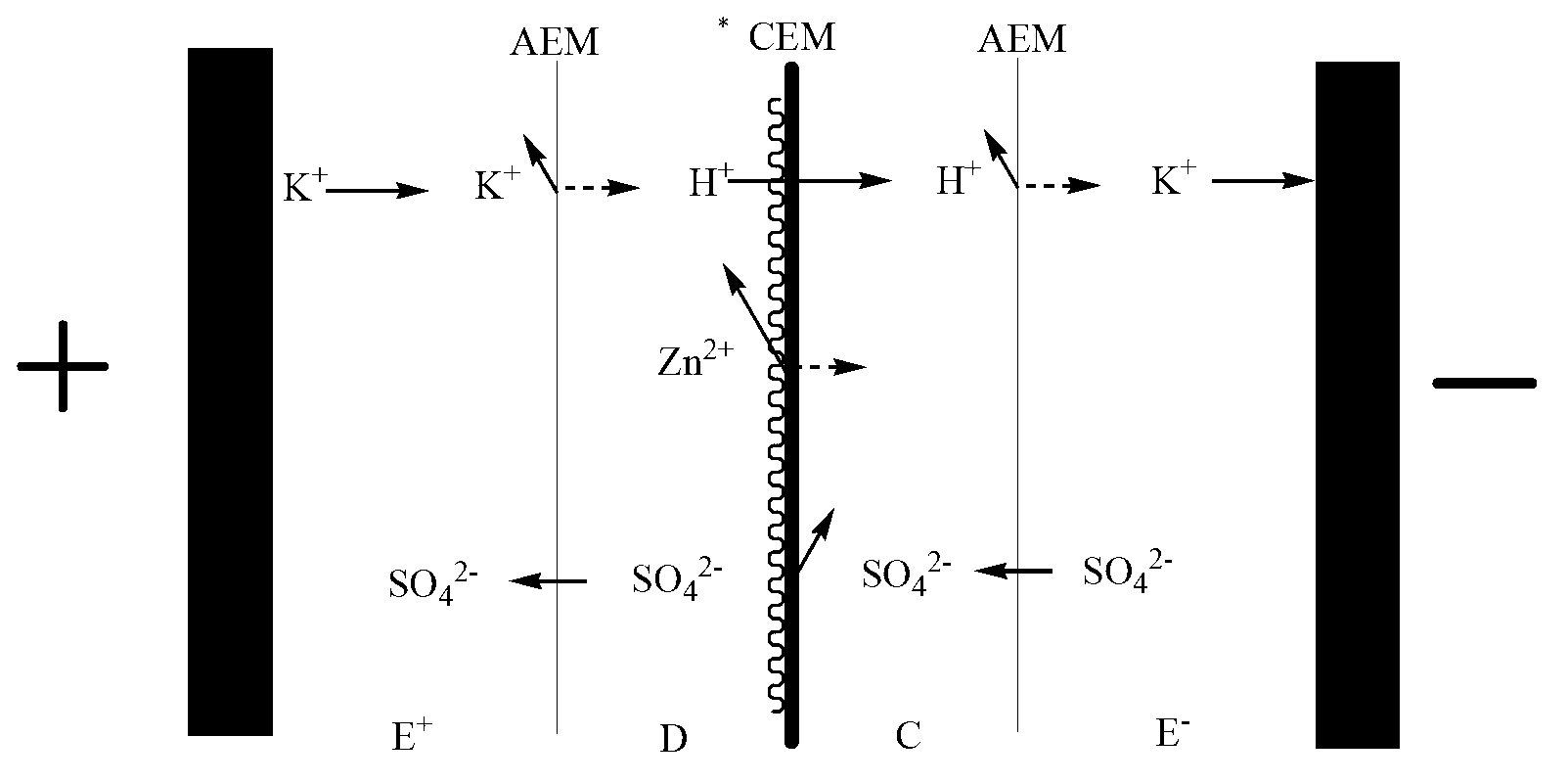

[0034]Cut the commercial homogeneous cation exchange membrane (Japan ASAHI GLASS CO., LTD product, SELEMION CMV) into a suitable size (5cm×5cm), roughen the surface of the membrane with sandpaper (2000 mesh), and soak it in a concentration of 2% chitosan in 2% acetic acid solution for 24 hours. The membrane was removed and drained, then immersed in H again 2 SO 4 (16 wt.%)—Na 2 SO 4 (19 wt.%)-formaldehyde (7 wt.%) cross-linking system, cross-linking in a constant temperature water bath at 60°C for 24 hours. Finally, the surface of the above-mentioned membrane was thoroughly washed with 2% acetic acid solution, 1% NaOH solution and deionized water in sequence, then immersed in 30% glyceryl ether trimethylammonium chloride aqueous solution, and kept at 50°C for 24 hours to realize the membrane Surface charge. Take out the membrane and wash the surface of the membrane with deionized water, soak in 0.1mol / L NaCl solution for testing. The surface morphology at different stage...

Embodiment 2

[0038] Cut the commercial heterogeneous cation exchange membrane (product of Zhejiang Qianqiu Environmental Protection Water Treatment Co., Ltd.) into a suitable size (5cm×5cm), roughen the surface of the membrane with sandpaper (3000 mesh), and soak it in a shell with a concentration of 0.5% at room temperature. Glycans in 1% acetic acid solution for 24 hours. Take the film out and drain it, then immerse it again in an alkaline cross-linking system (pH=10, adjusted with potassium hydroxide) composed of acetone (45, wt%)-epichlorohydrin (50, wt%)-water (5, wt%) ) at 45°C for 20 hours. Finally, the surface of the above-mentioned membrane was thoroughly washed with 2% acetic acid solution, 1% NaOH solution and deionized water in sequence, then immersed in 30% glyceryl ether trimethylammonium chloride aqueous solution, and kept at 50°C for 24 hours to realize the membrane Surface charge. Take out the membrane and wash the surface of the membrane with deionized water, soak in 0....

Embodiment 3

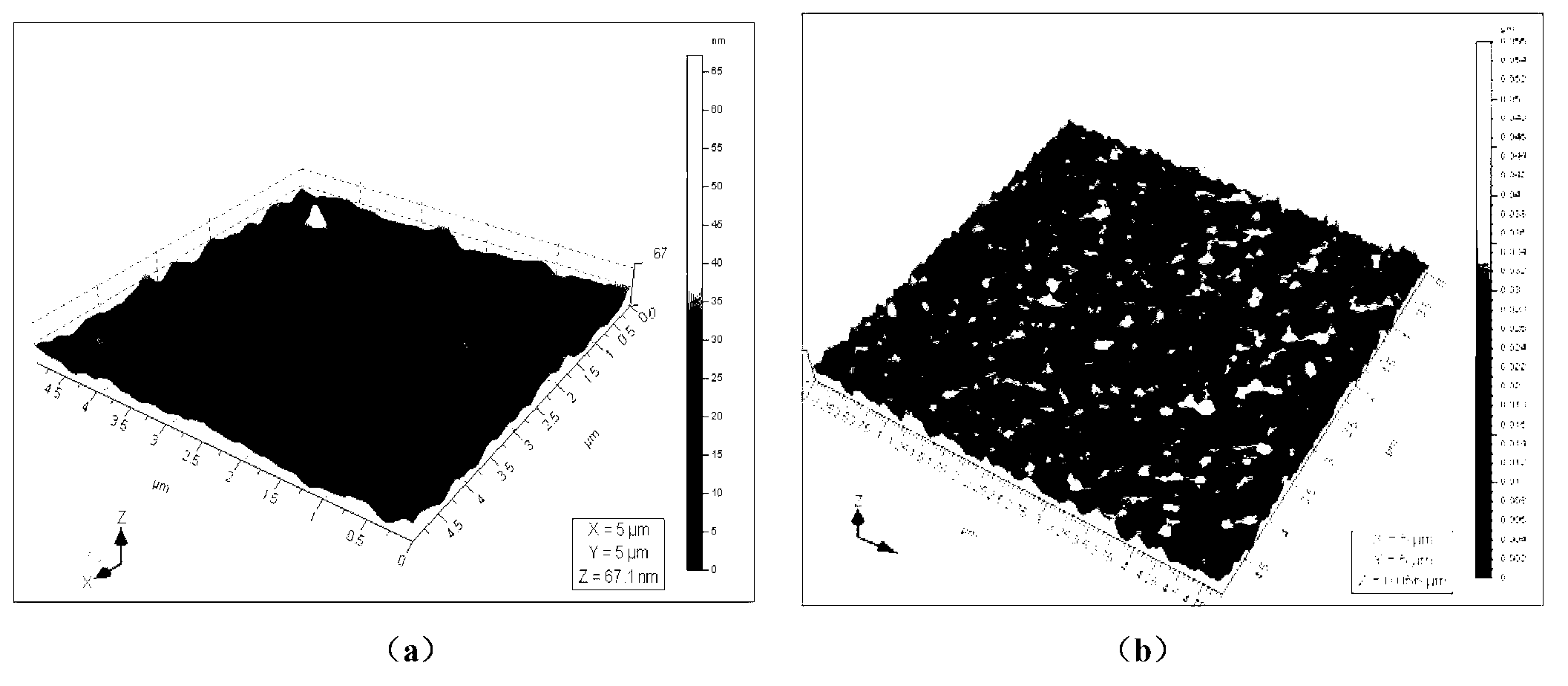

[0041] Cut the commercial homogeneous cation exchange membrane (Japan ASAHI GLASS CO., LTD product, SELEMION CMV) into a suitable size (5cm×5cm), roughen the surface of the membrane with sandpaper (2000 mesh), and soak it in a concentration of 0.5% chitosan azide derivatives (3% azide group content) in 2% acetic acid solution for 24 hours. After the film was taken out to avoid light and drained, it was irradiated with ultraviolet light (8W, UV-C) for 30 minutes, and then fully washed with 2% HAc, 0.05% NaOH, and deionized water in sequence. Comparison of basement membrane surface morphology before and after immobilization of chitosan azide derivatives figure 2 shown. After soaking the membrane in 40% formaldehyde solution for 2 hours, it was fully washed with 10% NaOH solution. Subsequently, the membrane was immersed in 4% glyoxal solution (adjusted pH to 4 with 50% KOH), cross-linked at 40°C for 75 minutes, and soaked in 0.5M hydrochloric acid for 1 hour. Finally, it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com