Method for preparing ethanol through acetic ester hydrogenation

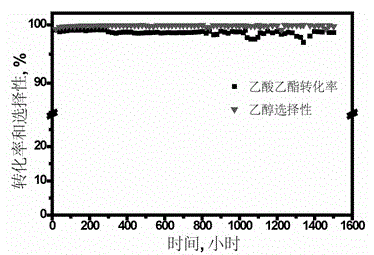

A technology for hydrogenation of acetate and production of ethanol, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve problems that have not yet been applied on a large scale, poor catalyst stability, harsh process conditions, etc., and achieve high heat Stability and hydrogenation activity and effects of stability, enhanced thermal stability, and improved anti-sintering ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

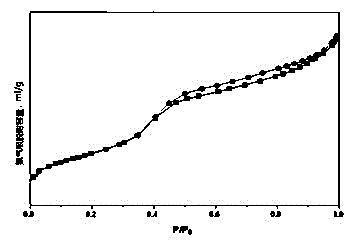

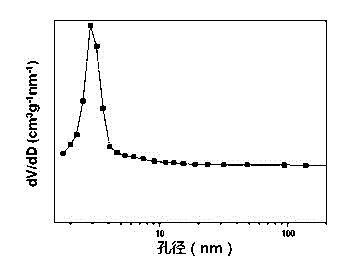

[0053] Catalyst preparation

[0054] Weigh 11 g of CTAB (cetyltrimethylammonium bromide) and place it in a beaker of 270 g of water and fully dissolve it, add 51.4 g of TEOS (tetraethyl silicate); then add 2.2 g of NaOH to make The pH value is between 11-11.5; raise the temperature of the water bath to 80°C and stir for 2 h to form the mother liquor of MCM-41 molecular sieve; weigh 15.2g Cu(NO 3 ) 2 ·3H 2 O and 51.7ml of 25% ammonia water were added to 150ml of water to form a cuproammonia solution; at room temperature, the cuproammonia solution was poured into the mother liquor of MCM-41 molecular sieves and stirred for 4h; weighed 0.53g La(NO 3 ) 3 ·6H 2 Add O into the slurry; then raise the temperature of the water bath to 80°C to volatilize the ammonia gas, stop heating when the pH value is lower than 7; then put the slurry into a stainless steel crystallization kettle and crystallize at 120°C 24 hours; after the crystallization was completed, take it out and cool, fi...

Embodiment 2

[0058] Catalyst preparation

[0059] Weigh 11 g of CTAB and place it in a beaker of 270 g of water and fully dissolve it, add 59.4 g of TEOS; then add 2.2 g of NaOH to make the pH value between 11-11.5; increase the temperature of the water bath to 80 ° C and stir for 2 h forms the mother liquor of MCM-41 molecular sieve; Weigh 7.6g Cu(NO 3 ) 2 ·3H 2 O and 25.8ml of 25% ammonia water were added into 150ml water to form a cuproammonia solution; at room temperature, the cuproammonia solution was poured into the mother liquor of MCM-41 molecular sieves and stirred for 4h; weighed 1.06g La(NO 3 ) 3 ·6H 2 O was added to the slurry; then the water bath was heated to 80°C to volatilize the ammonia gas, and the heating was stopped when the pH value was lower than 7; then the slurry was put into a stainless steel crystallization kettle and crystallized at 120°C for 24 hours; after the crystallization is completed, take it out and cool it, filter it, and wash it until neutral; then...

Embodiment 3

[0063] Catalyst preparation

[0064] Weigh 11 g of CTAB, place it in a beaker of 270 g of water and fully dissolve it, add 40 g of TEOS; then add 2.2 g of NaOH to make the pH value between 11-11.5; increase the temperature of the water bath to 80 °C and stir for 2 h Form the mother liquor of MCM-41 molecular sieve; Weigh 22.8g Cu(NO 3 ) 2 ·3H 2 O and 77.5ml of 25% ammonia water were added to 150ml of water to form a cuproammonia solution; at room temperature, the cuproammonia solution was poured into the mother liquor of MCM-41 molecular sieves and stirred for 4 h; weighed 2.7g La(NO 3 ) 3 ·6H 2 O was added to the slurry; then the water bath was heated to 80°C to volatilize the ammonia gas, and the heating was stopped when the pH value was lower than 7; then the slurry was put into a stainless steel crystallization kettle and crystallized at 120°C for 24 hours; after the crystallization is completed, take it out and cool it, filter it, and wash it to neutrality; then dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com