Production method of soybean isoflavone glycoside

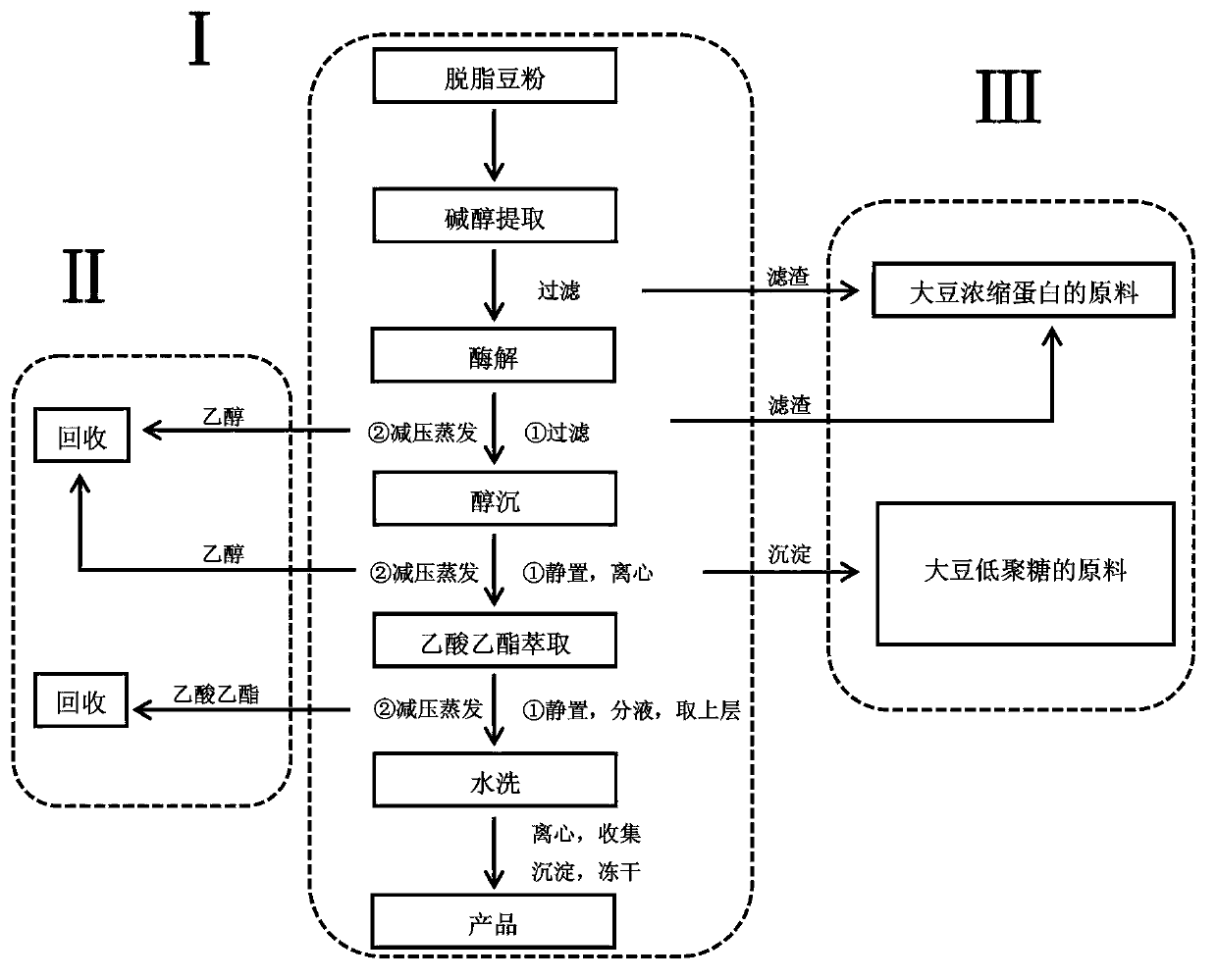

A technology of isoflavone aglycone and soybean isoflavone, which is applied in the field of preparing high-purity soybean isoflavone aglycone, can solve the problems of toxic organic solvent residue, low extraction rate, time and energy consumption, etc., and achieves easy industrial production and improved extraction The effect of speed and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Alkaline ethanol aqueous solution extraction

[0026] Crush the defatted soybean meal and pass through a 60-80 mesh sieve. Take 10g 60~80 mesh defatted soybean meal powder, dissolve in 100ml 70% ethanol solution, Ca(OH) 2 Adjust the pH to 9.0, place the system in a constant temperature water bath at 70°C for extraction, stir and extract for 2 hours, after the extraction is complete, filter with suction to remove the filter residue, and take the supernatant for later use.

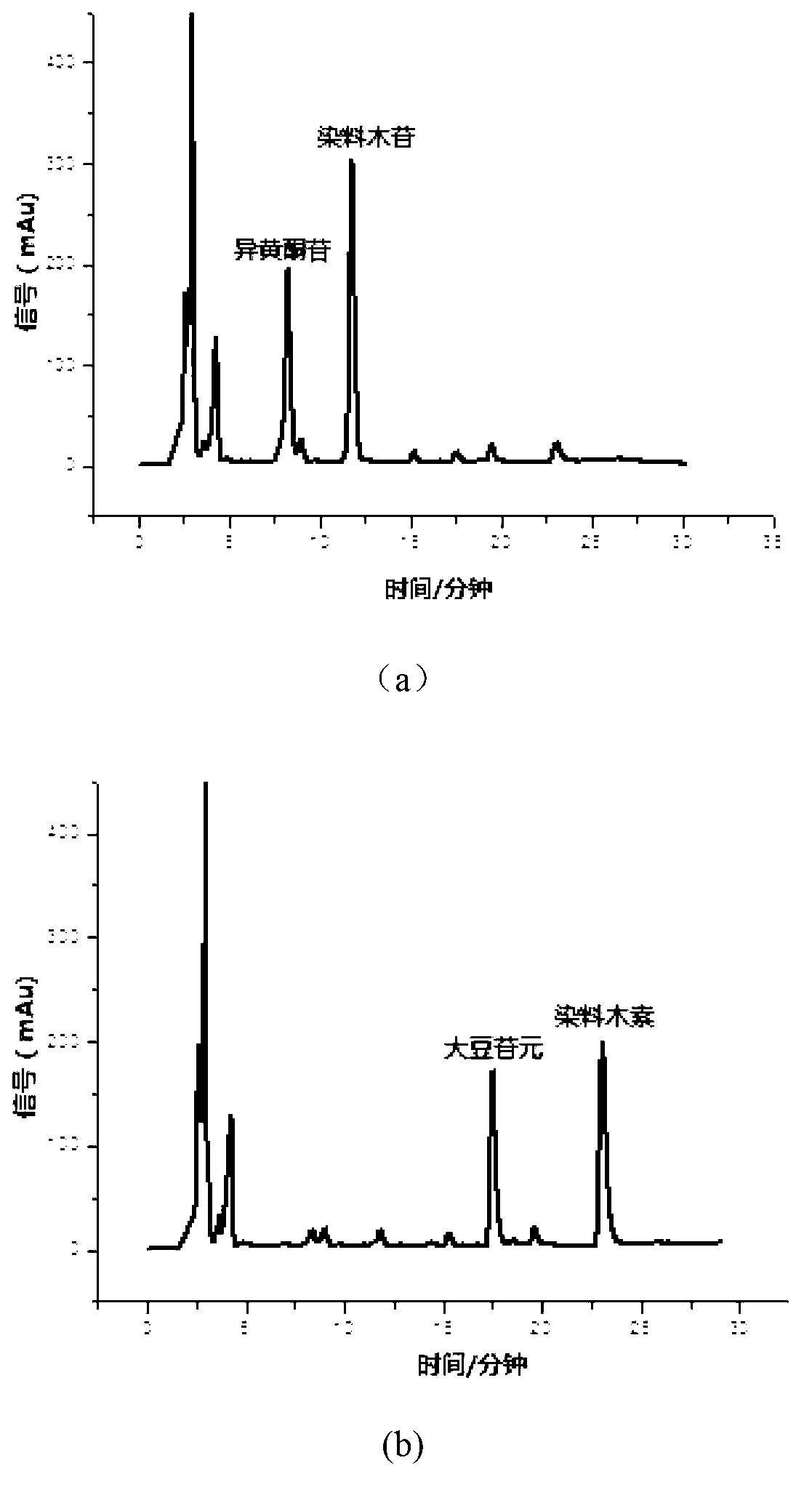

[0027] (2) Enzymatic hydrolysis of soybean isoflavones

[0028] Use HCl with a mass fraction of 15% to adjust the pH of the supernatant obtained in step (1) to 4.8, add GC22014.9U, place the system in a constant temperature water bath with a temperature of 50°C for reaction, and continue enzymatic hydrolysis for 4 hours. place, filter, and remove the precipitate to obtain the ethanol aqueous solution of soybean isoflavone aglycone, evaporate under reduced pressure to remove ethanol (recovery for...

Embodiment 2

[0036] (1) Alkaline ethanol aqueous solution extraction

[0037] Crush the defatted soybean meal and pass through a 60-80 mesh sieve. Take 10g 60~80 mesh defatted soybean meal powder, dissolve in 150ml 70% ethanol solution, Ca(OH) 2 Adjust the pH to 8.0, place the system in a constant temperature water bath at 60°C for extraction, stir and extract for 1 hour, after the extraction is complete, filter with suction to remove the filter residue, and take the supernatant for later use.

[0038] (2) Enzymatic hydrolysis of soybean isoflavones

[0039] Use HCl with a mass fraction of 15% to adjust the pH of the supernatant obtained in step (1) to 4.5, add GC22020.1U, place the system in a constant temperature water bath at 45°C for reaction, and continue the enzymatic hydrolysis for 4.5h. Stand still, filter, remove the precipitate, obtain the ethanol aqueous solution of soybean isoflavone aglycone, evaporate under reduced pressure to remove ethanol (recovery for use), obtain the w...

Embodiment 3

[0047] (1) Alkaline ethanol aqueous solution extraction

[0048] Crush the defatted soybean meal and pass through a 60-80 mesh sieve. Take 10g 60~80 mesh defatted soybean meal powder, dissolve in 200ml 70% ethanol solution, Ca(OH) 2 Adjust the pH to 10.0, place the system in a constant temperature water bath at 50°C for extraction, stir and extract for 2 hours, after the extraction is complete, filter with suction to remove the filter residue, and take the supernatant for later use.

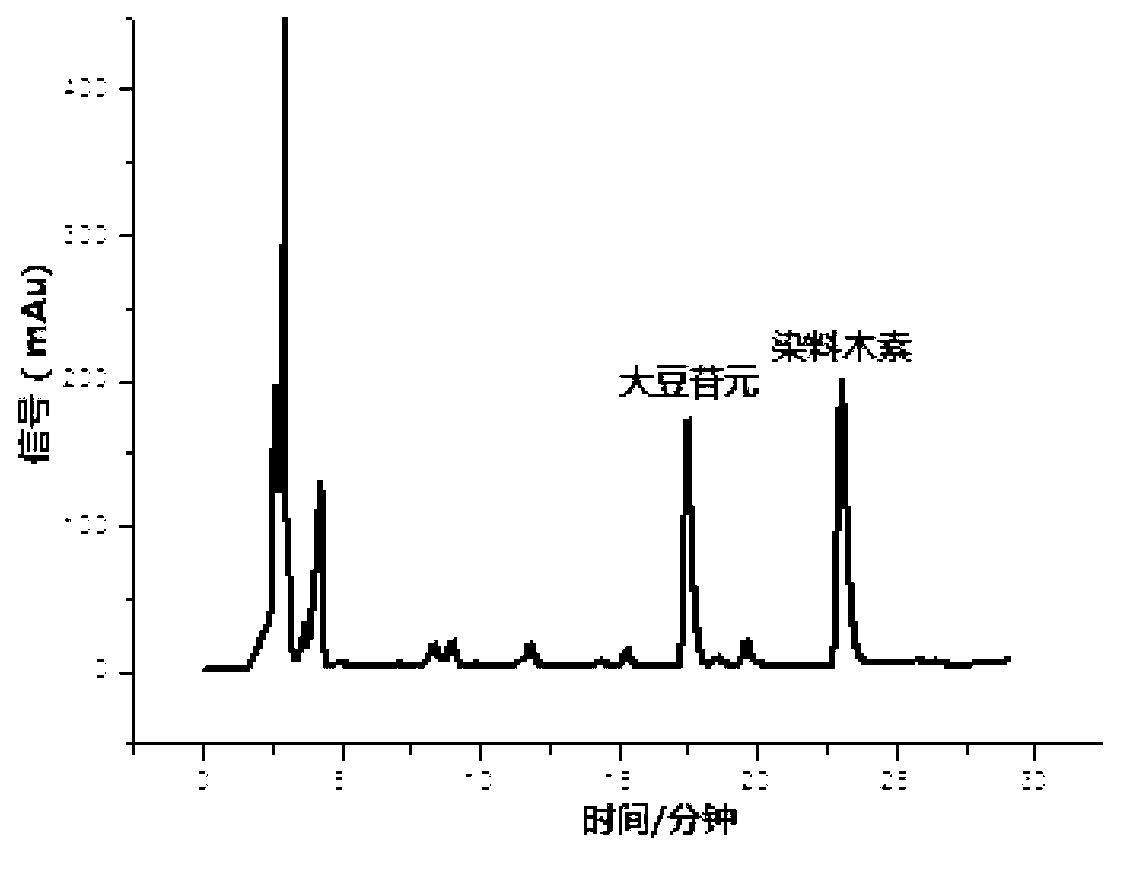

[0049] (2) Enzymatic hydrolysis of soybean isoflavones

[0050] Use HCl with a mass fraction of 15% to adjust the pH of the supernatant obtained in step (1) to 5.0, add GC22018.6U, place the system in a constant temperature water bath at 60°C for reaction, continue enzymatic hydrolysis for 3 hours, and statically place, filter, and remove the precipitate to obtain the ethanol aqueous solution of soybean isoflavone aglycone, evaporate under reduced pressure to remove ethanol (recovery for use), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com