Epoxy resin and nitrile rubber adhesive and preparing method thereof

A technology of nitrile rubber and epoxy resin, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of poor storage stability, poor impact resistance, poor cold resistance, etc., and achieve volatile Less, excellent heat resistance, good effect on environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

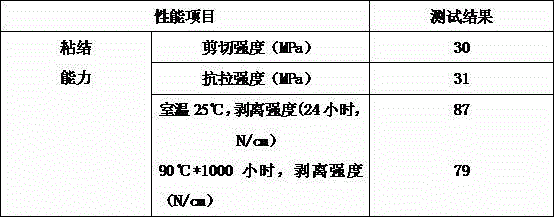

Image

Examples

Embodiment

[0015] An epoxy resin-nitrile rubber adhesive, made of the following raw materials in parts by weight: 115 parts of styrene, 145 parts of ethyl acetate, 25 parts of nitrile rubber N230S, 18 parts of xylene, 4,4'- 2 parts of diphenylmethane diisocyanate, 10 parts of polyisobutylene, 2 parts of 3-aminopropyltrimethoxysilane, 3 parts of polytetrahydrofuran ether glycol, 4 parts of SG-2 type PVC resin, 2 parts of ferrocene, modified 20 parts of permanent epoxy resin, 6 parts of EPDM rubber, 3 parts of phthalate, 4 parts of epoxy octyl stearate, 4 parts of epoxidized triglyceride, 3 parts of zinc oxide, dimercapto 1.5 parts of isooctyl di-n-octyl tin, 2 parts of zinc stearate, 25 parts of light calcium carbonate, 40 parts of nano attapulgite, 45 parts of carbon black N220, isopropyl tri(dioctyl pyrophosphate acyloxy ) 2 parts of titanate, 0.8 parts of antioxidant 1010, 1 part of anilinomethyltriethoxysilane, 1 part of crosslinking agent TAC, 1.5 parts of antioxidant OD, 2 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com