Acidolysis laterite nickel ore wastewater treatment and slag utilization method

A technology for the treatment of laterite nickel ore and wastewater, which is applied in mining wastewater treatment, water/sewage treatment, adsorbed water/sewage treatment, etc., can solve the problems of acid hydrolysis of nickel ore wastewater polluting environmental resources, etc., and achieves a simple and easy wastewater treatment process. Project implementation, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

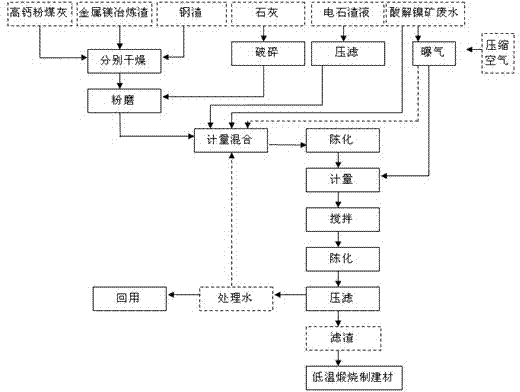

Image

Examples

Embodiment 1

[0028] Example 1: The method for the treatment of waste water of acidolysis laterite nickel ore and the utilization method of slag, the specific operation is as follows:

[0029] 1. Raw material processing and preparation

[0030] (1) Pretreatment of acid-decomposed laterite-nickel ore wastewater: Continuously inject compressed air into the acid-lysis laterite-nickel ore wastewater (magnesium ion concentration is 20g / L), and stop the exposure when the color of the wastewater turns from colorless to brown. Air, the aeration time is 2.0h, and the aeration liquid is obtained;

[0031] (2) Preparation of acid hydrolysis nickel ore wastewater treatment agent: first, high-calcium fly ash (in which CaO+MgO content is greater than 45%, SO 3 Content 6%, SiO 2 +Al 2 o 3 CaO content is 25%) dry grinding into 0.045mm sieve 18% powder material, calcium carbide slag (in which the CaO content is 71%) is press-filtered into a semi-solid with a moisture content of 50%; then the high calc...

Embodiment 2

[0043] Embodiment 2: the utilization method of acidolysis laterite nickel ore waste water treatment and slag, concrete operation is as follows:

[0044] 1. Raw material processing

[0045] (1) Pretreatment of acid-lysis laterite-nickel ore wastewater: Continuously inject compressed air into the acid-lysis laterite-nickel ore wastewater (magnesium ion concentration is 25g / L), and stop the exposure when the color of the wastewater turns from colorless to brown. Air, the aeration time is 2.5h, and the aeration liquid is obtained;

[0046] (2) Preparation of acid hydrolysis nickel ore wastewater treatment agent: first, metal magnesium smelting slag (in which the content of CaO+MgO is 47%, Si0 2 +Al 2 o 3 32%) dry powder material with a 0.045mm sieve residue of 16%, calcium carbide slag (in which the CaO content is 65%) is press-filtered to become a semi-solid with a moisture content of 40%; then the metal magnesium smelting slag and calcium carbide The slag is mixed in a rati...

Embodiment 3

[0055] Example 3: The method for the treatment of waste water of acidolysis laterite nickel ore and the utilization method of slag, the specific operation is as follows:

[0056] 1. Raw material processing

[0057] (1) Pretreatment of acid-decomposed laterite-nickel ore wastewater: Continuously inject compressed air into the acid-lysis laterite-nickel ore wastewater (magnesium ion concentration is 30g / L), and stop the exposure when the color of the wastewater turns from colorless to brown. Air, the aeration time is 3h, and the aeration liquid is obtained;

[0058] (2) Preparation of acidolysis nickel ore wastewater treatment agent: first steel slag (carbon steel slag or / and stainless steel slag, in which CaO+MgO content is 64%, SiO 2 +Al 2 o 3 23%) dry grinding to become a 0.045mm sieve powder material with a sieve residue of 16%, carbide slag (in which the CaO content is 69%) is press-filtered to become a semi-solid with a moisture content of 40%; then the steel slag and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| escape rate | aaaaa | aaaaa |

| escape rate | aaaaa | aaaaa |

| escape rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com