Preparation and application of high-purity lysophosphatidylcholine

A phosphatidylcholine, high-purity technology, applied in the field of preparation of high-purity lysophosphatidylcholine, can solve problems such as lack of sufficient research on efficacy and side effects, and achieve the effects of shortening reaction time, reducing reaction cost, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

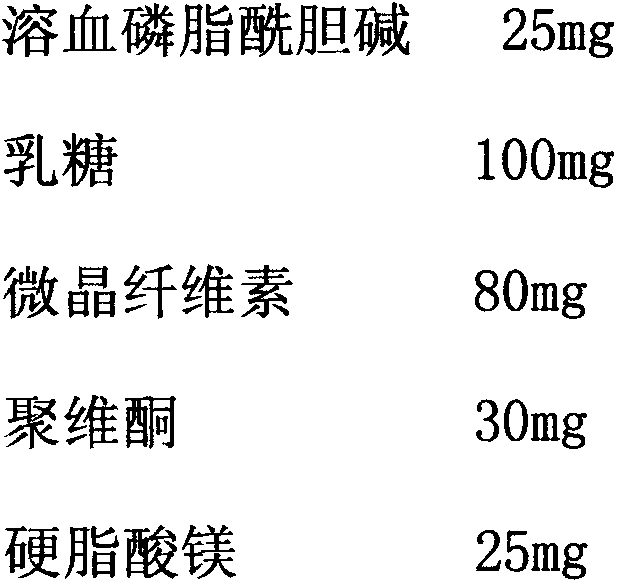

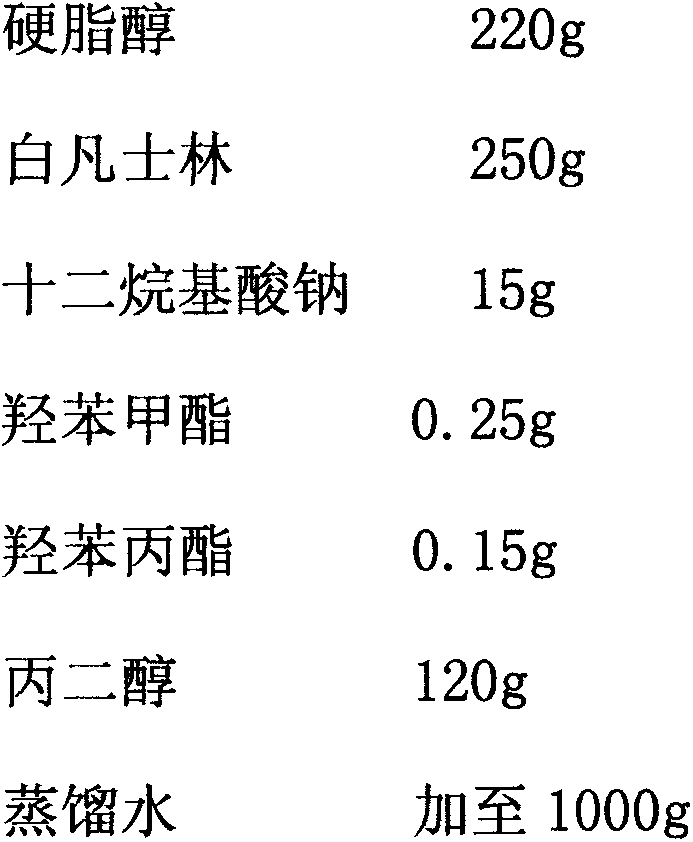

Examples

preparation Embodiment 1

[0028] Mix phosphatidylcholine and triglyceride, wherein the mass ratio of phosphatidylcholine and triglyceride is 1:1. The mixture was heated to 85°C to obtain a homogeneous melt. Add a sufficient amount of water and ether to form a solution, wherein the volume ratio of water and ether is 10:1, and heat to 80°C to mix the reactants uniformly. Adjust the pH to 8-9. Add 0.5 ml of an enzyme preparation of LecitaseTM10L phospholipase A2 per kilogram of phosphatidylcholine, and react for 36 hours under the conditions of keeping stirring and pH value until the phosphatidylcholine is completely hydrolyzed. After complete hydrolysis, water and ether were removed by heating to obtain a paste.

[0029] In order to obtain high purity lysophosphatidylcholine, the final product of the reaction is precipitated with acetone, which will separate the two components triglyceride and fatty acid from the above-mentioned hydrolyzate containing lysophosphatidylcholine, triglyceride and fatty aci...

preparation Embodiment 2

[0031] Mix phosphatidylcholine and triglyceride, wherein the mass ratio of phosphatidylcholine and triglyceride is 7:1. The mixture was heated to 85°C to obtain a homogeneous melt. Add a sufficient amount of water and ether to form a solution, wherein the volume ratio of water and ether is 8:1, and heat to 80°C to mix the reactants evenly. Adjust the pH to 8-9. According to every kilogram of phosphatidylcholine, 1ml of an enzyme preparation of LecitaseTM10L, a phospholipase A2, was added, and the mixture was reacted for 36 hours under the condition of stirring and pH value, until the phosphatidylcholine was completely hydrolyzed. After complete hydrolysis, water and ether were removed by heating to obtain a paste.

[0032] In order to obtain high purity lysophosphatidylcholine, the final product of the reaction is precipitated with acetone, which will separate the two components triglyceride and fatty acid from the above-mentioned hydrolyzate containing lysophosphatidylcholi...

preparation Embodiment 3

[0034] Shell the castor beans, smash them, and then degrease: add 4mL of diethyl ether and petroleum ether mixture per gram of castor beans and mix evenly, then use the Buchner funnel to suction filter, and then use the above degreasing method to degrease the material on the filter paper 3 times, Then the components on the filter paper are dried to obtain the loose castor-oil biscuit powder after oiling, for subsequent use; the mixed solution of diethyl ether and sherwood oil, wherein the volume ratio of diethyl ether and sherwood oil is 1:1;

[0035] Wrap the prepared castor biscuit powder with filter paper, put it into a Soxhlet extractor, add ethanol with a mass concentration of 95% according to the ratio of adding 10 mL of ethanol per gram of castor biscuit powder, extract for 8 hours, and obtain a yellow-brown oily substance for extraction Liquid, and then distilled to 1 / 5 of the original volume with a rotary evaporator to obtain a paste, and then according to the ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com