Preparation method of lactobacillus johnsonii microcapsule, microcapsule and application of additive

A technology of Lactobacillus johnsonii and microcapsules, which is applied in the field of high-density fermentation of lactic acid bacteria and microcapsule coating, can solve the problems of less feeding, difficult process control, and complicated operation, so as to reduce energy consumption and environmental pollution, avoid The damage of the material, the effect of prolonging the storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

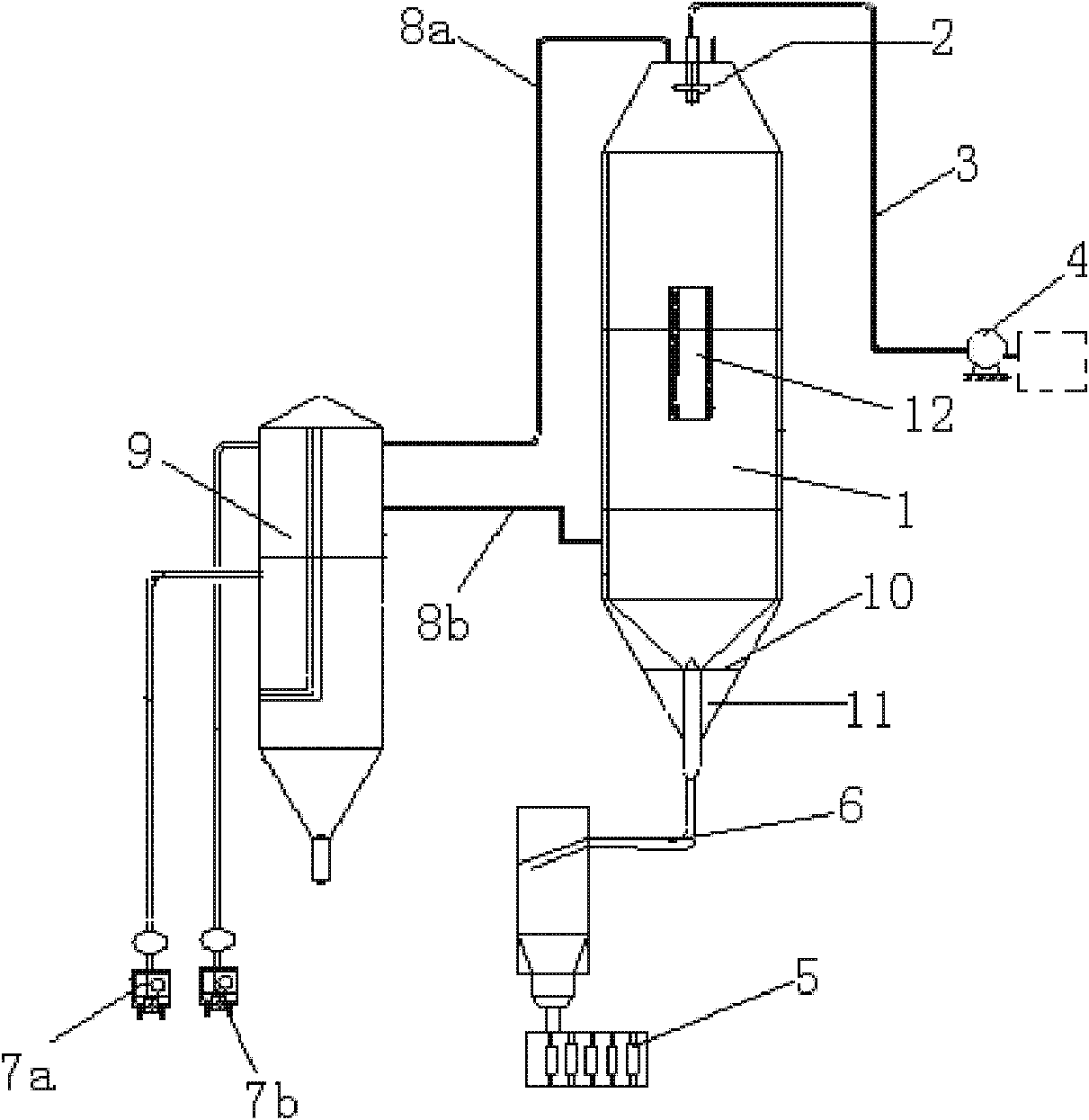

Image

Examples

Embodiment 1

[0044] a. Bacteria activation:

[0045] The cryopreserved Lactobacillus johnsonii was inoculated into the MRS liquid medium, cultured at 37° C. for 18 hours, and passed down once in this way to obtain the activated Lactobacillus johnsonii strain.

[0046] b. Preparation of culture medium:

[0047] First, take the following raw materials respectively: 90 parts by weight of brown sugar, 8 parts by weight of yeast extract powder, 30 parts by weight of soybean peptone, 3 parts by weight of dipotassium hydrogen phosphate, 13 parts by weight of sodium acetate, 0.8 parts by weight of MgSO 4 ·7H 2 O, 0.04 parts by weight MnSO 4 ·5H 2 O: Add the above raw materials to 1000 parts by weight of water, stir evenly, adjust the pH value to 6.4 with 30% sodium hydroxide, and then sterilize at a temperature of 115° C. for 15 minutes to obtain the fermentation medium;

[0048] C, the preparation of strain fermented liquid:

[0049] Based on the weight of the medium used, inoculate the acti...

Embodiment 2

[0067] a. Bacteria activation:

[0068] The frozen Lactobacillus johnsonii (Lactobacillus johnsonii) CGMCC No.4926 was inoculated in MRS liquid medium, cultured at 37° C. for 20 h, and passed twice in this way to obtain the activated Lactobacillus johnsonii strain.

[0069] b. Preparation of culture medium:

[0070] First, take the following raw materials respectively: 115 parts by weight of brown sugar, 10 parts by weight of yeast extract powder, 40 parts by weight of soybean peptone, 3.2 parts by weight of dipotassium hydrogen phosphate, 14 parts by weight of sodium acetate, 0.9 parts by weight of MgSO 4 ·7H 2 O, 0.06 parts by weight MnSO 4 ·5H 2 O: Stir the above raw materials and 1000 parts by weight of water evenly, use 35% NaOH to adjust the pH value to 6.6, and then sterilize at a temperature of 121° C. for 15 minutes to obtain the fermentation medium;

[0071] C, the preparation of strain fermented liquid:

[0072] Based on the weight of the medium used, the activ...

Embodiment 3

[0084] a. Bacteria activation:

[0085] The frozen Lactobacillus johnsonii (Lactobacillus johnsonii) CGMCC No.4926 was inoculated in MRS liquid medium, cultured at 37° C. for 20 h, and passed twice in this way to obtain the activated Lactobacillus johnsonii strain.

[0086] b. Preparation of culture medium:

[0087] First, take the following raw materials respectively: 120 parts by weight of brown sugar, 12 parts by weight of yeast extract powder, 50 parts by weight of soybean peptone, 3.5 parts by weight of dipotassium hydrogen phosphate, 15 parts by weight of sodium acetate, 1.0 parts by weight of MgSO 4 ·7H 2 O, 0.08 parts by weight MnSO 4 ·5H 2 O: Add the above raw materials into 1000 parts by weight of water, stir evenly, use 40% NaOH to adjust the pH value to 6.6, and then sterilize at a temperature of 115° C. for 20 minutes to obtain the fermentation medium;

[0088] C, the preparation of strain fermented liquid:

[0089] Based on the weight of the medium used, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com