Redispersable nanoparticle powder material preparation method

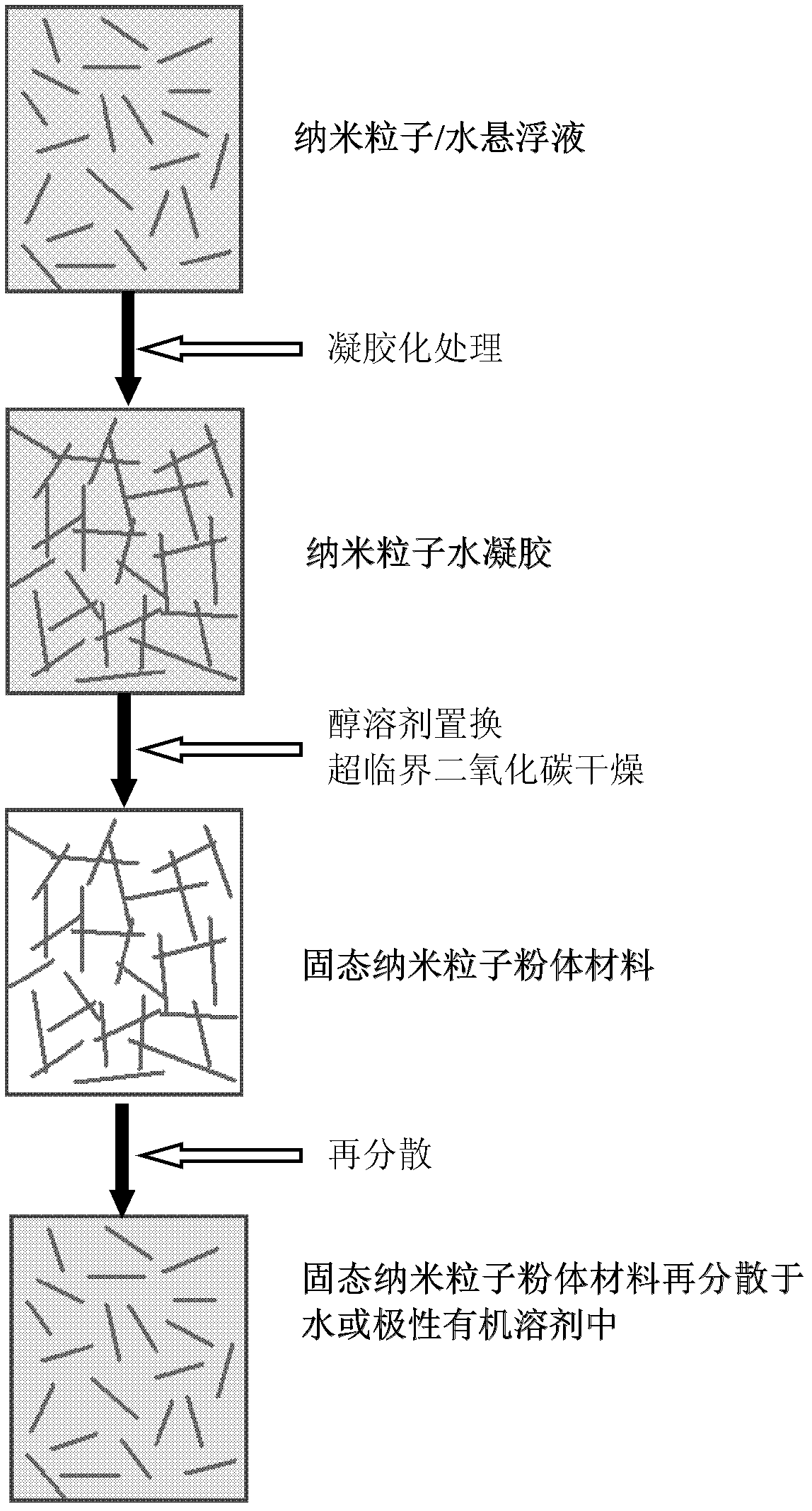

A technology of nanoparticles and powder materials, which is applied in the field of preparation of nano-particle powder materials, can solve the problems that it is difficult to avoid the re-aggregation of nanoparticles and the difficulty of re-dispersion of nano-particle materials, and achieve the effect of easy dispersion and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, preparation redispersible nano-cellulose whisker

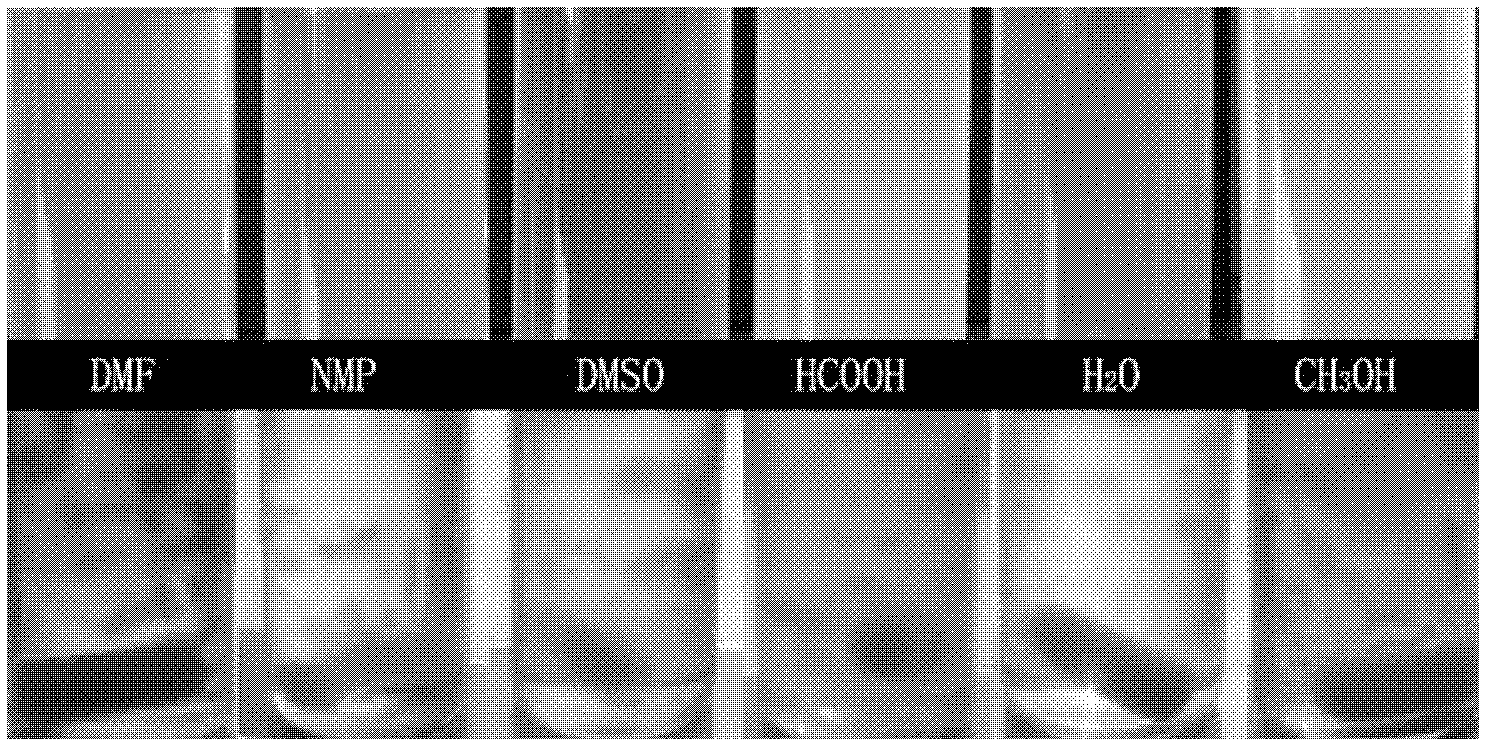

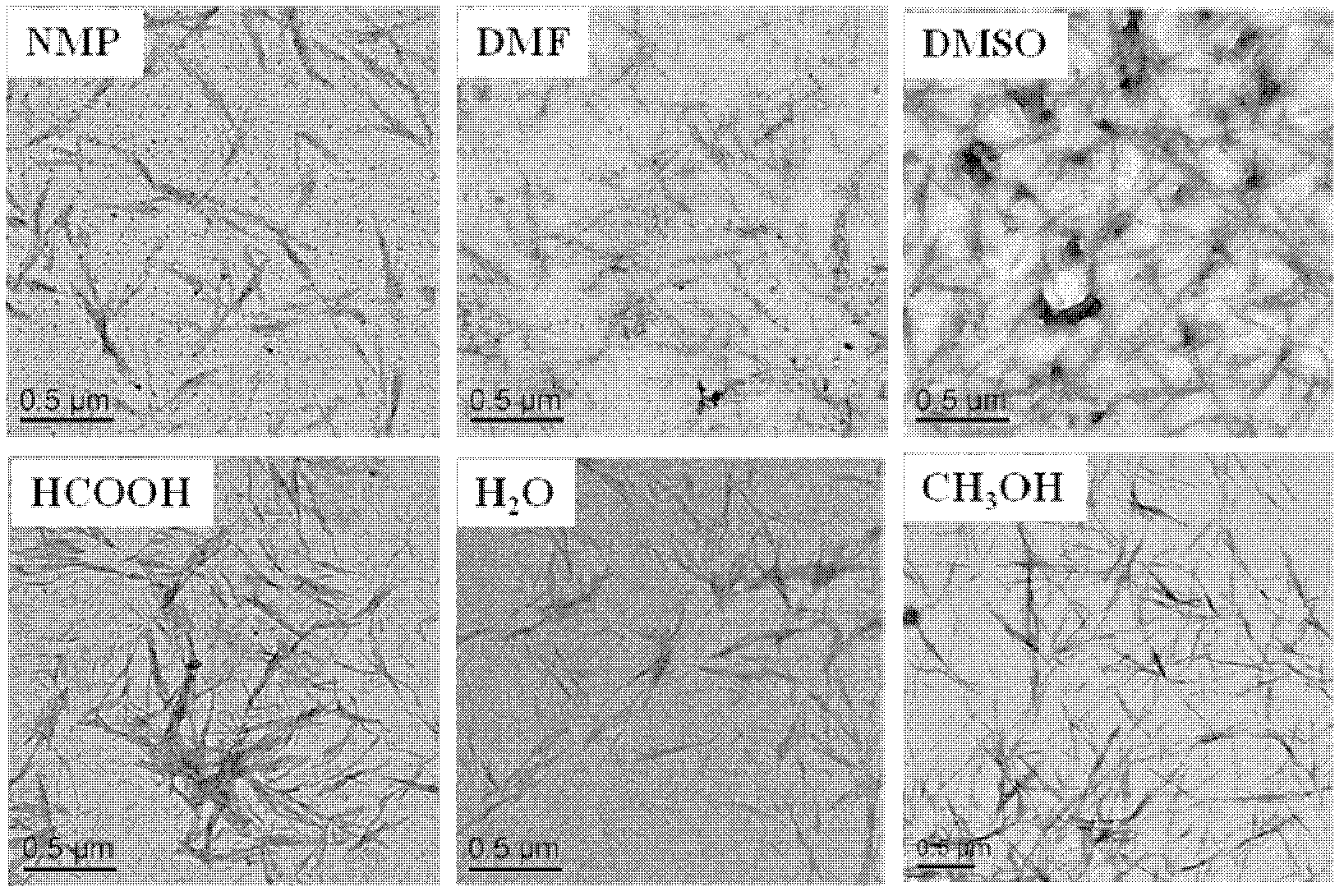

[0028] Weigh the dry microcrystalline cellulose (polymerization degree 220) that has been vacuum-dried at 80°C for 12 hours and disperse it in secondary water, add concentrated sulfuric acid dropwise under ice bath to make the concentration of microcrystalline cellulose 10.2g / 100mL, sulfuric acid The mass concentration was 63.5%, and then heated to 44° C. within 5 minutes, mechanically stirred for 2 hours, and then centrifuged to remove the surface suspension (centrifugation until the upper layer was turbid). Ultrasonic dispersion of the resulting white slurry is followed by dialysis until the pH value remains constant, (at this time the concentration is greater than 1%) to obtain an aqueous solution of nanocellulose whiskers, and an appropriate amount of hydrochloric acid with a mass concentration of 36.5% is added to form a nanocellulose whisker / water solution. gel. The water in the gel was replaced wit...

Embodiment 2

[0029] Embodiment 2, preparation redispersible cellulose nanofiber

[0030] 1g of cellulose fibers was added to TEMPO (2,2,6,6-tetramethylpiperidine oxide) (0.016g), NaBr (0.1g) in 100mL aqueous solution, and then added dropwise with pH value of 12, NaClO The content is 12% aqueous solution, so that the final concentration of NaClO is 4 mmol. Then stir at room temperature, add dropwise 0.5M NaOH to adjust the pH value to be stable at about 10, until the dropwise addition of NaOH is no longer required. Then the obtained oxidized cellulose is treated with ultrasonic and homogenizer to obtain oxidized nanofibrils, and the obtained oxidized nanofibrils (containing -COONa) are washed to neutral with deionized water, and then the mass concentration of cellulose obtained after oxidation is Adjust to 0.1%, add dropwise 1M HCl under stirring condition, adjust the pH to 1, at this time a transparent cellulose nanofibril gel is formed. The gel is replaced with ethanol to obtain alcohol...

Embodiment 3

[0031] Embodiment 3, preparation redispersible lithium magnesium silicate particle

[0032] 2.5g dried lithium magnesium silicate powder (commodity ) was dispersed in 97.5mL of secondary water, mechanically stirred at room temperature for 4h to obtain a transparent nanoscale dispersion of lithium magnesium silicate; the resulting aqueous dispersion was allowed to stand overnight, during which the suspension gelled to obtain Lithium magnesium silicate hydrogel. The water in the hydrogel is replaced by ethanol until the water is completely replaced by ethanol, and then supercritical carbon dioxide is dried to obtain a solid lithium magnesium silicate nanoparticle powder material. The powder material obtained by drying is light blue. The lithium magnesium silicate nanoparticle powder material can be well redispersed in water and dimethyl sulfoxide, N,N-dimethylacetamide, N,N-dimethylformamide, pyridine and N-formaldehyde In polar organic solvents such as pyrrolidone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com