Ultrathin, self-supporting, flexible, all-solid-state supercapacitor and preparation method thereof

A supercapacitor and solid electrolyte technology, applied in the field of electrochemical energy storage, can solve the problems of poor bonding between electrode materials and solid electrolyte, failure to achieve less than 10 μm, power and energy density attenuation, etc., to reduce overall quality and thickness, high The effect of specific capacitance and reduction of equivalent internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

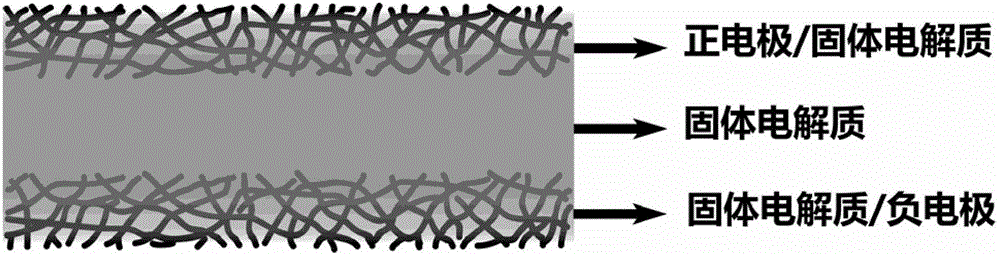

[0049] The preparation method of the ultra-thin, self-supporting, flexible, all-solid-state supercapacitor of the embodiment of the present invention comprises the following steps:

[0050] 1) Firstly, carbon nanomaterials or carbon nanocomposite electrodes are prepared and pretreated: the prepared positive electrode material and negative electrode material are respectively tiled on substrates with different surface energies.

[0051] 2) Thermal drip irrigation or printing of the solid electrolyte on the positive and negative electrode materials on the surface of the substrate, after soaking, use the glue-spinning method to remove the excess solid electrolyte, and then obtain the positive electrode / solid electrolyte, negative electrode / solid electrolyte film.

[0052] 3) Lay the positive electrode / solid electrolyte and negative electrode / solid electrolyte film with the substrate symmetrically together, and after standing and drying, the device assembly is completed;

[0053]...

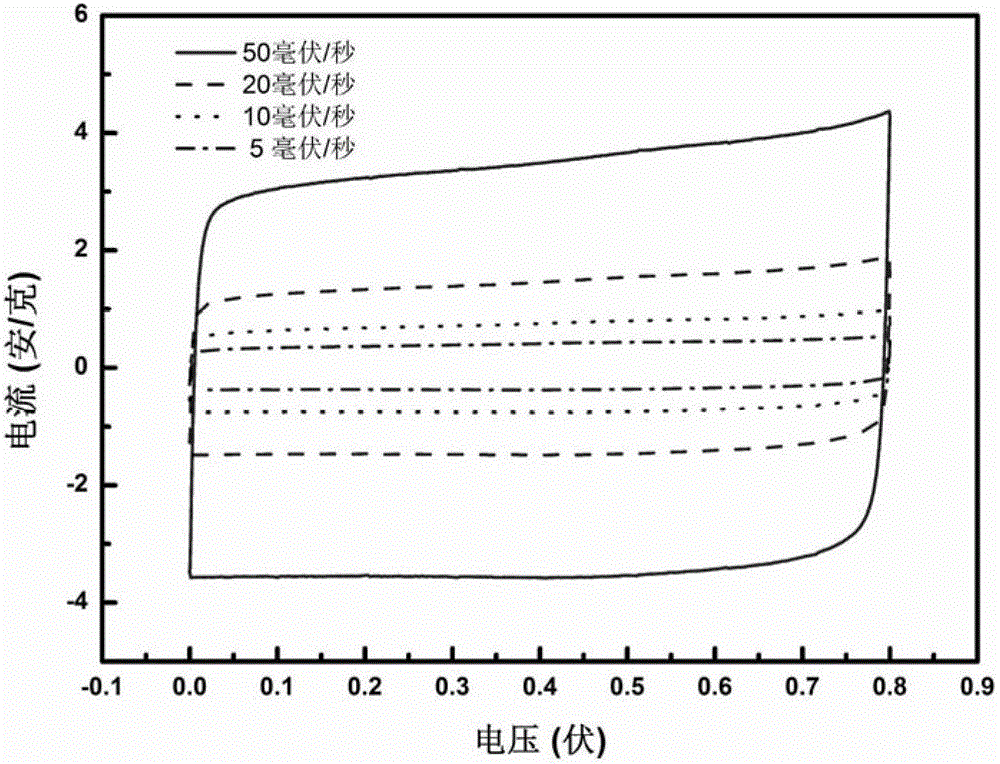

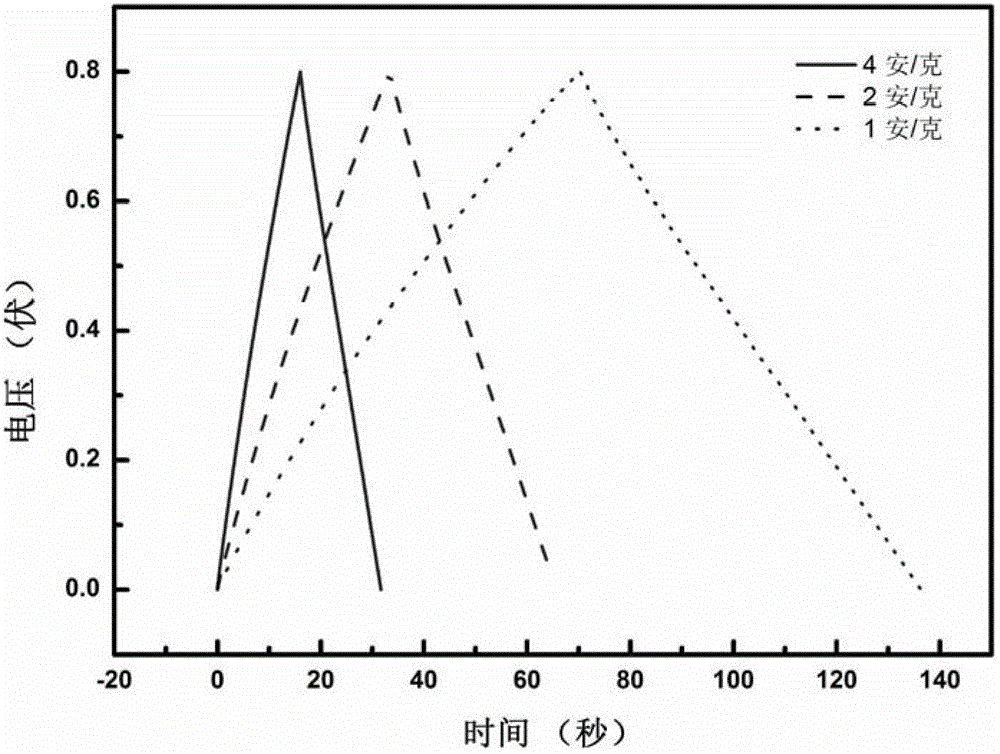

Embodiment 1

[0062] 1) Preparation and pretreatment of electrode materials

[0063] First, the carbon nanotube film directly grown by the floating catalytic chemical vapor deposition method was cut and spread on a hollow polytetrafluoroethylene (PVDF) rectangular frame (1.8×2.5cm 2 ). Subsequently, the carbon nanotube film was immersed in an aqueous solution containing 0.01M 3,4-ethylenedioxythiophene monomer and 0.1M sodium p-toluenesulfonate, and the polycarbonate was deposited on the carbon nanotube film by the constant potential electrochemical deposition method. 3,4-ethylenedioxythiophene, polymerization potential 1V, polymerization time 40 seconds. After the deposition is completed, a carbon nanotube / polyethylenedioxythiophene composite material is obtained, wherein the poly3,4-ethylenedioxythiophene content is 85%. Subsequently, the carbon nanotube / poly-3,4-ethylenedioxythiophene composite film was removed from the PVDF rectangular frame, and spread on a polyethylene terephthalate...

Embodiment 2

[0069] 1) Preparation and pretreatment of electrode materials

[0070] First, the carbon nanotube film directly grown by the floating catalytic chemical vapor deposition method was cut and spread on a hollow PVDF rectangular frame (1.8×2.5cm 2 ). Then the carbon nanotube film was immersed in an aqueous solution containing 0.1M aniline monomer, 0.25M sulfuric acid, and 0.25M sodium sulfate, and polyaniline was electrochemically deposited using a potentiostatic method with a polymerization potential of 0.75V and a polymerization time of 30 seconds. In the prepared composite film material, the content of polyaniline is about 75wt.%. Subsequently, the obtained carbon nanotube / polyaniline composite film was transferred from the PVDF frame to a styrene (PS) substrate and a PVDF substrate for use. In this embodiment, the thickness of the carbon nanotube film is selected to be about 100 nm.

[0071] 2) Assembly of ultra-thin, self-supporting, flexible supercapacitors

[0072] This...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface energy | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com