A kind of modification method of carbon fiber surface

A modification method and carbon fiber technology, applied in fiber processing, textile and papermaking, physical processing, etc., can solve the problems of difficult industrial production, unfriendly environment, long process route, etc., and achieve low cost, environmental friendly, simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Weigh 0.01 g of graphene oxide, dissolve it in 1 liter of deionized aqueous solution, use 0.1 mol / L NaOH solution to adjust the pH value of the solution to 10.0; then mechanically stir at 100 rpm for 2 hours to make it evenly dispersed.

[0041] Take the mesophase pitch-based carbon fiber and wind it on the tetrafluoroethylene plate as the anode of the CHI660A electrochemical workstation, the platinum wire as the cathode, and the Ag / AgCl electrode as the reference electrode. The carbon fiber was immersed in the graphene oxide dispersion solution, the solution temperature was 20°C, and the electrophoretic coating was performed by applying a voltage of 10 volts for 10 minutes, and the distance between the working electrode and the counter electrode was 5 cm. Then the carbon fiber was taken out, and stayed in a heating furnace at 80° C. for 60 minutes, the atmosphere was air, and the modified carbon fiber was obtained. The tensile strength of carbon fiber before modificati...

Embodiment 2

[0043] Weigh 2 grams of graphene oxide, dissolve it in 1 liter of deionized water, and adjust the pH value of the solution to 8.0 with 0.1 mol / liter NaOH solution; then mechanically stir at a speed of 20 rpm for 60 hours to make it evenly dispersed.

[0044] Take polyacrylonitrile carbon fiber and wind it on a tetrafluoroethylene plate as the anode of CHI660A electrochemical workstation, platinum wire as cathode, and Ag / AgCl electrode as reference electrode. The carbon fiber is immersed in the graphene oxide dispersion, the solution temperature is 60 ° C, and the electrophoretic coating is carried out for up to 3 hours by applying a voltage of 1 volt, and the distance between the working electrode and the counter electrode is 10 cm, and the process is assisted by ultrasonic waves. dispersion. Then the carbon fiber was taken out, and stayed in a heating furnace at 600° C. for 10 seconds under an ammonia atmosphere to obtain a modified carbon fiber. The tensile strength of the ...

Embodiment 3

[0046] Weigh 1 gram of graphene oxide, dissolve it in 1 liter of deionized water, adjust the pH value of the solution to 13.0 with 0.1 mol / L NaOH solution; then stir it with a mechanical stirrer at a speed of 300 rpm for 1 hour to make it evenly dispersed .

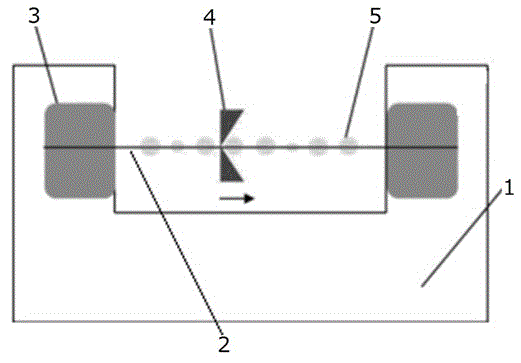

[0047] The graphene oxide emulsion is placed in a plexiglass electrolytic cell, the carbon fiber is used as the anode, the graphite plate is used as the cathode, and a DC power supply is provided by a DC stabilized current power supply. The polyacrylonitrile carbon fiber tow is continuously passed through the electrolytic cell through the guide roller, the solution temperature in the electrolytic cell is 80 ° C, and the distance between the working electrode and the counter electrode is 20 cm by applying a voltage of 60 volts for 5 seconds; After coming out of the tank, it passes through a high-temperature heat treatment furnace continuously. The temperature in the furnace is 600°C, the atmosphere is nitrogen, and the res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com