Cable and application thereof to electric power system

A technology for cables and cable conductors, which is applied to cables and their applications in power systems. It can solve the problems of low tensile strength and hardness, poor flame-retardant properties of cable insulation, etc., and achieve better flame-retardant insulation and radiation resistance. Reduced possibility of breakage and damage, effects of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A cable, consisting of a cable conductor and an insulating material wrapped on the cable conductor, the insulating material is prepared from the following raw materials in parts by weight: 100 parts of liquid bisphenol F epoxy resin, 60 parts of phenolic resin powder, 30 parts of silicon carbide Parts, 20 parts of white carbon black, 15 parts of zinc N-ethyl-N-phenyldithiocarbamate, 10 parts of calcium carbonate, 10 parts of cryolite, 8 parts of N-phenyl-2-naphthylamine, stearin 7 parts of acid, 6 parts of magnesium hydroxide, 6 parts of zinc borate, 3 parts of triallyl isocyanurate, 2 parts of dimethylaminoethoxyethanol, and 2 parts of short peptide. The particle size of phenolic resin powder and white carbon black is controlled below 10um; the particle size of silicon carbide, calcium carbonate and cryolite is controlled below 1um; the short peptide is Gly-Thr-Gly-Gly.

[0020] The preparation method of the above-mentioned insulating material is as follows: take each ...

Embodiment 2

[0022] A cable insulating material, prepared from the following raw materials in parts by weight: 90 parts of bisphenol F epoxy resin (liquid bisphenol F epoxy resin), 50 parts of phenolic resin powder, 25 parts of silicon carbide, and 18 parts of white carbon black Parts, 12 parts of zinc N-ethyl-N-phenyldithiocarbamate, 8 parts of calcium carbonate, 8 parts of cryolite, 6 parts of N-phenyl-2-naphthylamine, 5 parts of stearic acid, hydrogenated Magnesium 4 parts, zinc borate 4 parts, triallyl isocyanurate 2 parts, dimethylaminoethoxyethanol 2 parts, short peptide 2 parts. The particle size of phenolic resin powder and white carbon black is controlled below 10um; the particle size of silicon carbide, calcium carbonate and cryolite is controlled below 1um; the short peptide is Pro-Gly-Val-Thr-Val.

[0023] The preparation method of the above insulating material is as follows: take each raw material according to the weight ratio, pour it into a high-speed mixer, stir and mix at ...

Embodiment 3

[0025] Various performance parameter tests of the insulating material prepared by the present invention

[0026] 1. Flame retardant performance test:

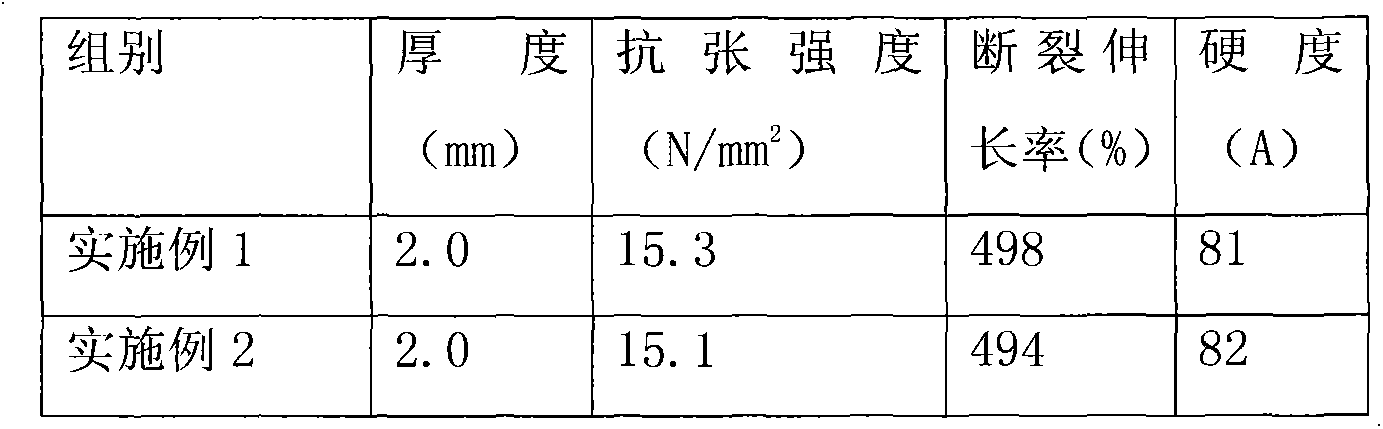

[0027] Table 1

[0028]

[0029] Conclusion: The cable insulation material prepared by the invention has good mechanical properties and can be applied to various cable materials.

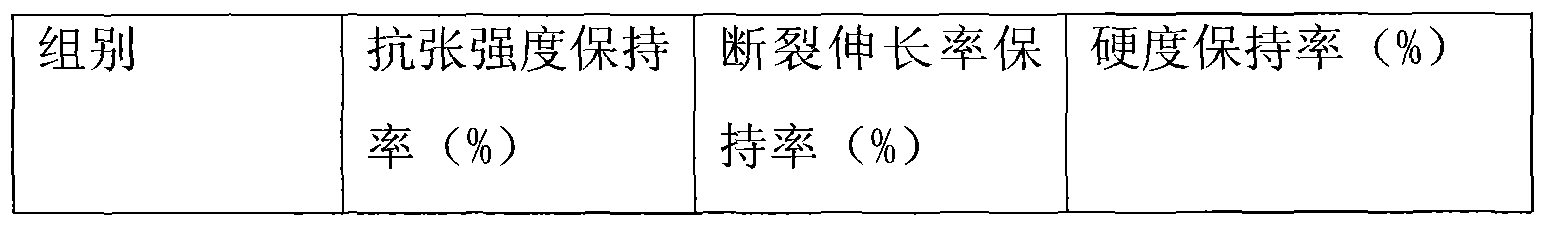

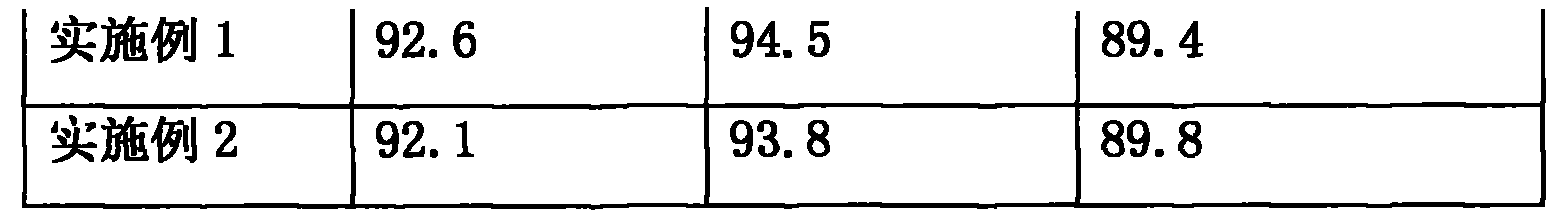

[0030] 2. After γ-ray irradiation (radiation dose is 1000kGy), the change of mechanical properties:

[0031]

[0032]

[0033] Conclusion: After γ-ray irradiation, the tensile strength, elongation at break and hardness do not decrease significantly, and the radiation resistance is better.

[0034] 3. Flame retardant and insulating properties:

[0035] table 3

[0036]

[0037] Conclusion: It has good insulation performance and high oxygen index. It is a flame retardant material and has a good flame retardant effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com