Preparation method and application of nano alpha-FeOOH/oxidized graphene

A graphene and graphene dispersion technology, applied in the interdisciplinary field, can solve the problems of easy inactivation of natural enzymes, low catalytic activity, and non-recyclability, etc., and achieve simple equipment, cheap and easy-to-obtain raw materials, and simple and reliable preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

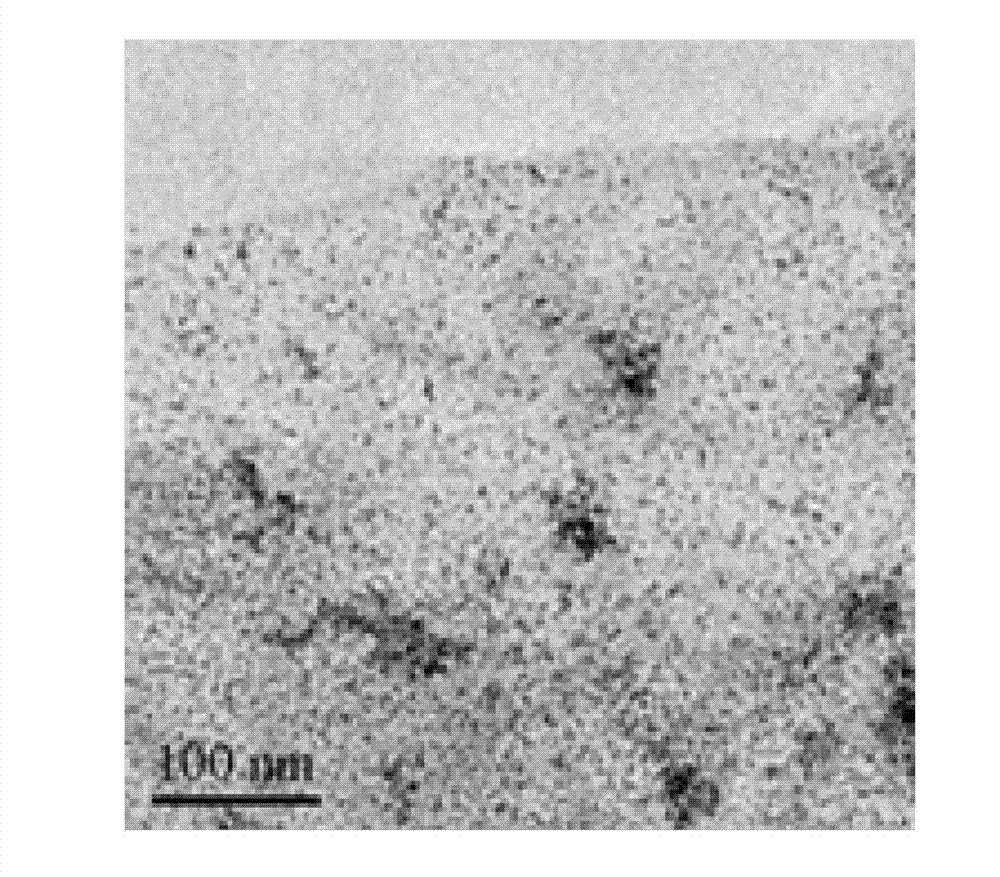

[0029] A preparation method of nano-α-FeOOH / graphene oxide, the steps are as follows:

[0030] (1) Graphite oxide was prepared by the Hummers method. The specific steps were: add 115 mL of 98% concentrated H 2 SO 4 Add 5g of graphite powder (natural flake graphite powder, particle size 4μm) while stirring, and then slowly add 15g of KMnO 4 , plus KMnO 4 During the process, the reaction temperature was controlled to be lower than 20°C. After the addition, the temperature was raised to 35°C and kept constant. After stirring for 2 hours, 230 mL of distilled water was added, and the temperature was raised to 98°C and kept stirring for 15 minutes. Then, 350 mL of distilled water and 13 mL of 30% H were added. 2 o 2 , continue to stir the reaction for 5min. The resulting product was washed and centrifuged several times until the supernatant was washed with BaCl 2 SO not detected 4 2- So far, finally dry in a vacuum oven to obtain graphite oxide;

[0031] (2) Take 0.4g of gra...

Embodiment 2

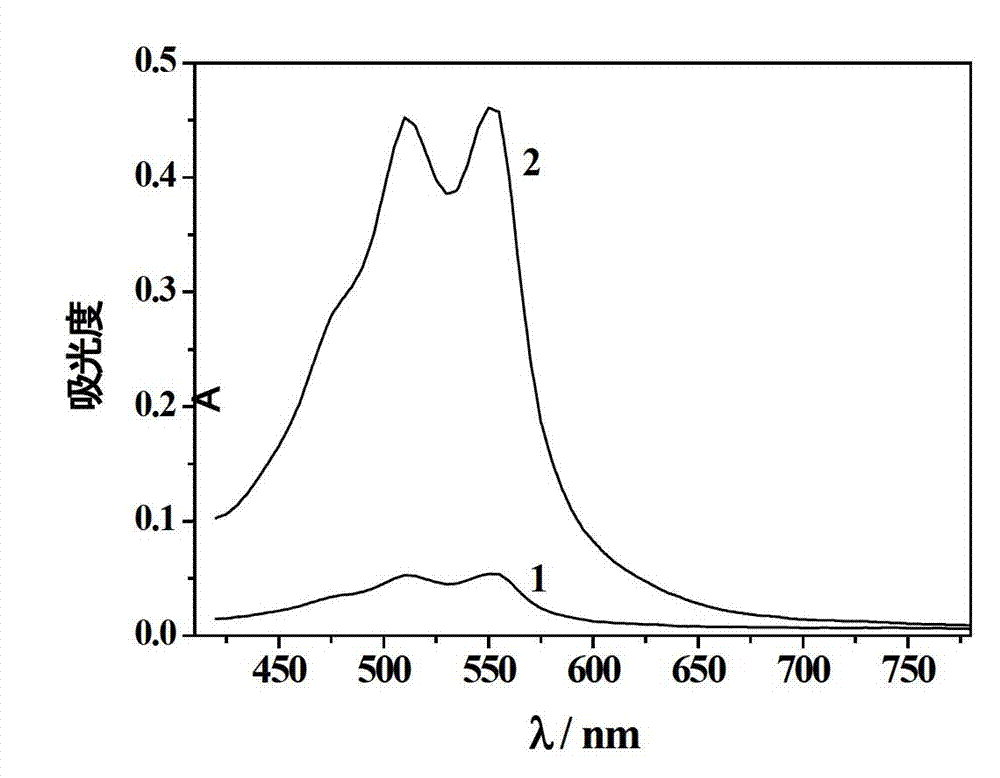

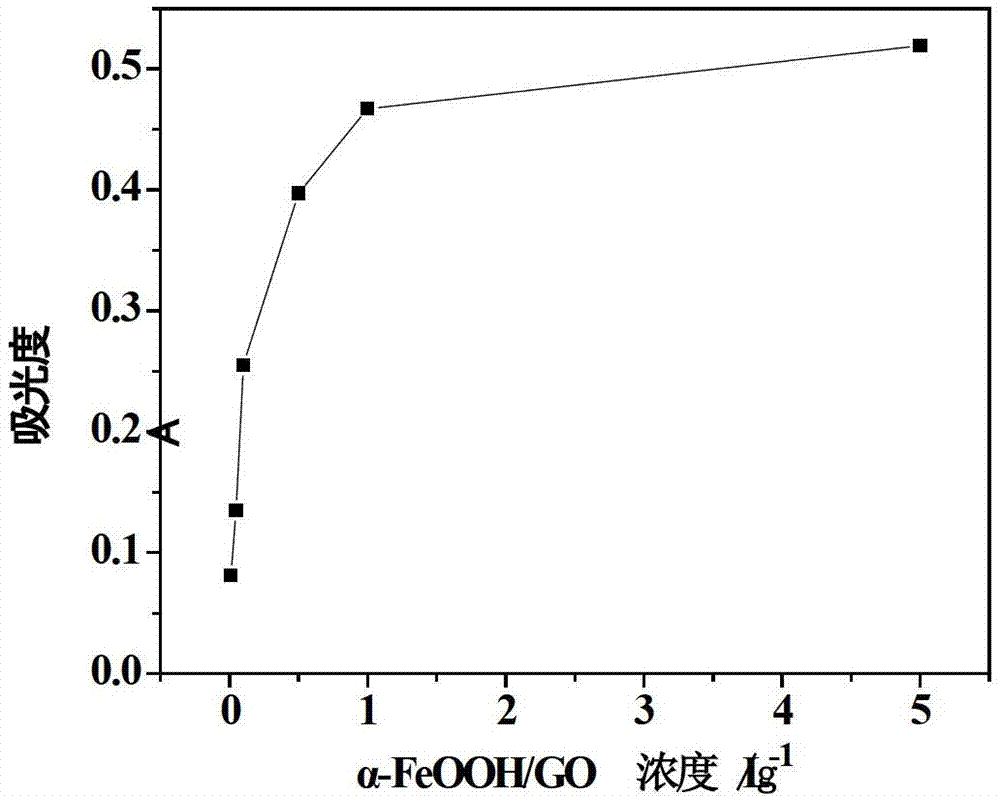

[0035] Utilize the nano-α-FeOOH / graphene oxide dispersion liquid of the 8.0g / L that embodiment 1 prepares to measure the method for hydrogen peroxide as the catalyst, the step of its working curve making is as follows:

[0036] (1) Add 0.40mL NaAc-HAc buffer solution (pH4.0) with a concentration of 0.1mol / L, 0.80mL with a concentration of 1.875×10 -2 mol / L N,N-diethyl-p-phenylenediamine sulfate solution, 8.0g / L nanometer α-FeOOH / graphene oxide dispersion liquid and 1.80mL double distilled water that 0.50mL embodiment 1 makes, ultrasonic Disperse to obtain a mixed solution. Accurately pipette 0.50mL of hydrogen peroxide solutions of different concentrations into the mixed solution, and place it in a water bath at 40°C for 20 minutes;

[0037] The concentrations of the hydrogen peroxide solutions with different concentrations are 0.8, 1.6, 4.0, 8.0, 16.0, 40.0, 80.0, 160.0, 400.0, 800.0, 1600.0, 2400.0 μmol / L;

[0038] (2) Centrifuge after the reaction, use twice distilled wate...

Embodiment 3

[0041] In order to study the effect of reaction pH value on the absorbance of the system, pH optimization experiments were carried out. Except that the pH values of the buffer solution were 3.5, 4.0, 4.5, 5.0, 5.5, and 6.0, the other reaction conditions and operations were exactly the same as in Example 2. The results showed that the absorbance of the system was the highest when the pH value was 4.0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com