Method for producing r-acetoin by Klebsiella pneumoniae

A kind of technology of pneumonia bacillus and acetoin is applied in the field of production of R-acetoin to achieve the effects of high conversion rate, high optical purity and high final concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026]The Klebsiella pneumoniae CGMCC1.6366budC mutant strain was used to ferment glucose to produce R-acetoin. The CGMCC1.6366 strain in this example was preserved by the China General Microorganism Culture Collection and Management Center, and had ampicillin resistance.

[0027] 1. Construction of Klebsiella pneumoniae CGMCC1.6366budC mutant strain

[0028] Proceed as follows:

[0029] 1. Use PCR to amplify Klebsiella pneumoniae acetoin reductase (budC) and the upstream and downstream adjacent sequences, connect to the cloning vector by TA cloning method, and perform DNA sequence determination.

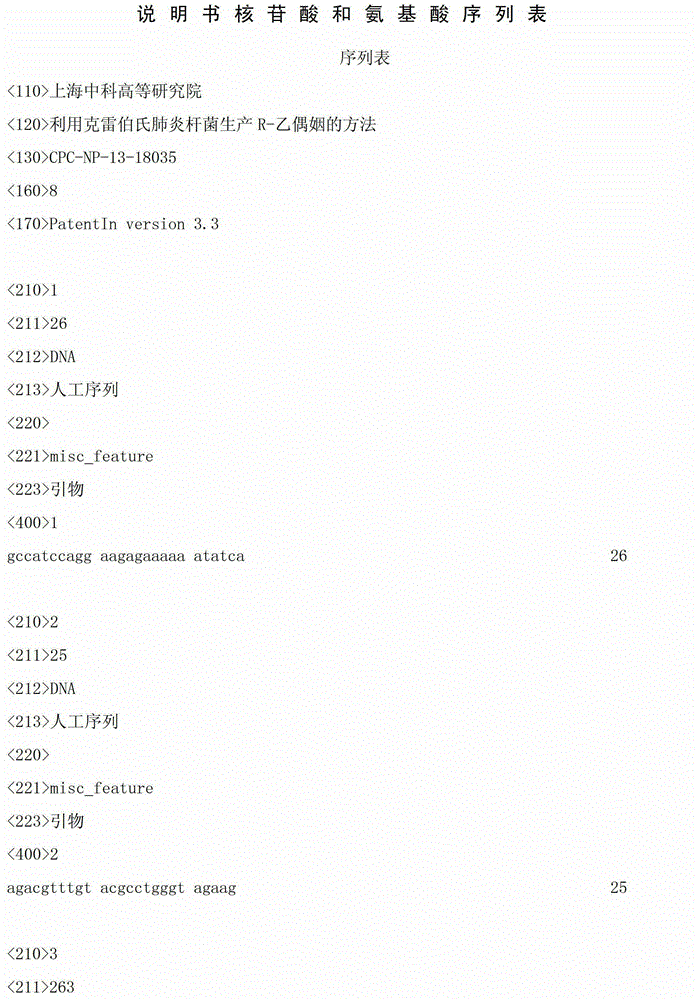

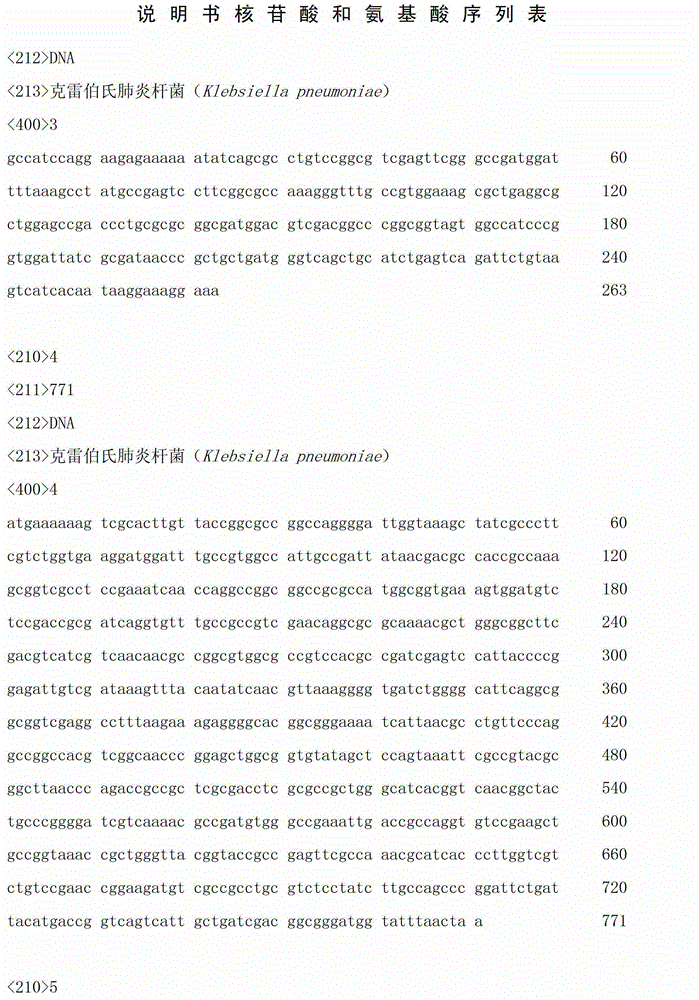

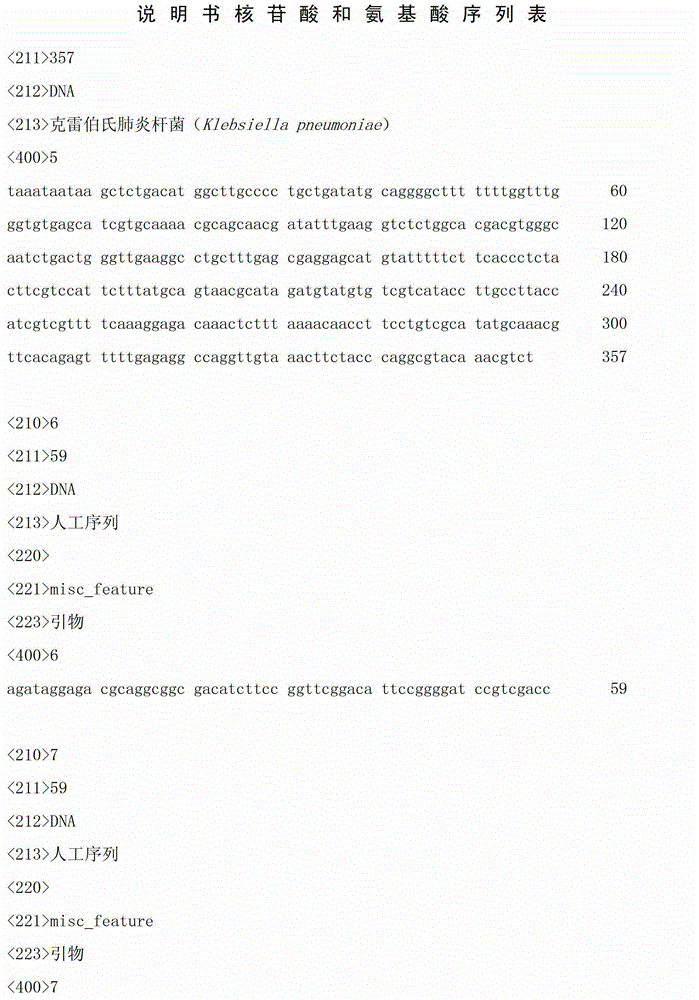

[0030] According to the genome information of Klebsiella pneumoniae MGH78578 (Genbank: CP000647), acetoin reductase PCR primers were designed, the upstream primer budC-s: GCCATCCAGGAAGAGAAAAAATATCA (shown in SEQ ID NO.1), the downstream primer budC-a: AGACGTTTGTACGCCTGGGTAGAAG ( shown in SEQ ID NO.2).

[0031] Using the above primers, Klebsiella pneumoniae CGMCC1.6366 genomic DNA ...

Embodiment 2

[0064] 1) Prepare seed medium

[0065] Peptone 10g / L, yeast powder 5g / L, sodium chloride 5g / L, prepared with tap water, dispensed into 250mL Erlenmeyer flasks with a liquid volume of 50mL, and sterilized.

[0066] 2) Allocation of glucose and other components into fermentation medium

[0067] Glucose monohydrate 50g / L, corn steep liquor powder 5g / L, sodium nitrite 0.1g / L, diammonium hydrogen phosphate 3.3g / L, dipotassium hydrogen phosphate 13.7g / L, potassium dihydrogen phosphate 2.0g / L, sulfuric acid Magnesium 0.25g / L, ferrous sulfate 0.05g / L, manganese sulfate 0.001g / L, trace element solution 1mL / L medium, tap water to prepare 3L, put into a 5L stirred fermenter, and sterilize. After sterilization, the measured glucose content was 42.7g / L.

[0068] Among them, the formula of trace element solution is: zinc chloride 70mg / L, sodium molybdate 35mg / L, boric acid 60mg / L, cobalt chloride 200mg / L, copper sulfate 29.28mg / L, nickel chloride 25mg / L.

[0069] 3) Seed culture

[0070...

Embodiment 3

[0075] 1) Prepare seed medium

[0076] Peptone 10g / L, yeast powder 5g / L, sodium chloride 5g / L, prepared with tap water, dispensed into 250mL Erlenmeyer flasks with a liquid volume of 50mL, and sterilized.

[0077] 2) Allocation of glucose and other components into fermentation medium

[0078] Glucose monohydrate 100g / L, peptone 10g / L, ammonium nitrate 5.5g / L, diammonium hydrogen phosphate 3.3g / L, dipotassium hydrogen phosphate 13.7g / L, potassium dihydrogen phosphate 2.0g / L, trace element solution 1mL / L medium, tap water to prepare 3L, put into a 5L stirred fermenter, and sterilize. After sterilization, the measured glucose content was 88g / L.

[0079] Among them, the formula of trace element solution is: zinc chloride 70mg / L, sodium molybdate 35mg / L, boric acid 60mg / L, cobalt chloride 200mg / L, copper sulfate 29.28mg / L, nickel chloride 25mg / L.

[0080] 3) Seed culture

[0081] Insert the Klebsiella pneumoniae CGMCC1.6366-budC- bacterial lawn prepared in Example 1 into the E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com