Method for preparing fermentable sugar from water-washed alkaline pretreated plant fiber raw material

A plant fiber and fermentable sugar technology, which is applied in the field of fermentable sugar preparation, can solve the problems of large water consumption, large amount of waste water, high production cost, etc., and achieve the effects of ensuring recovery, ensuring high efficiency, and reducing inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1 The washing of green liquid pretreatment corn stalk

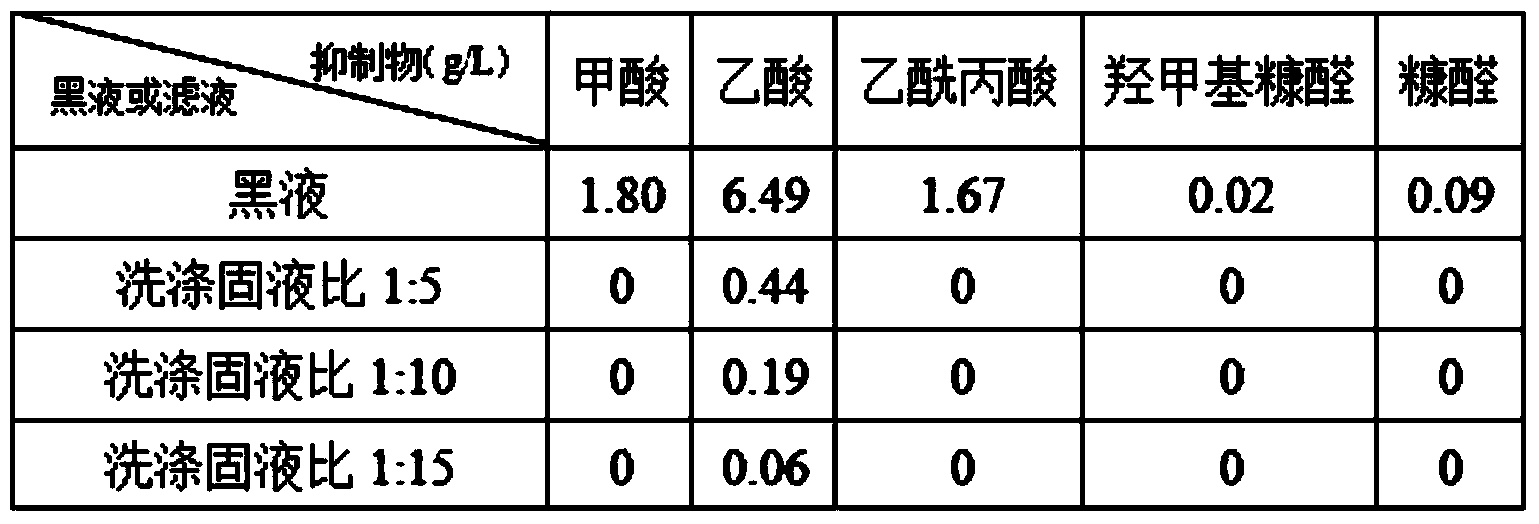

[0021] Corn stalks are crushed to 2-5cm, and the green liquor (Na 2 CO 3 and Na 2 S) is the pretreatment cooking liquid, the amount of alkali used is 8% (w / w), the degree of sulfidation is 40%, the ratio of cooking solid to liquid is 1:6 (w / v), after idling at 60°C for 0.5h, the temperature Raise it to 140°C, keep it warm for 1 hour, and after cooling, refine and filter out most of the black liquor together with the black liquor to recover chemicals. The filtered corn stalks are neutralized with acid and washed in three batches with solid-to-liquid ratios of 1:5, 1:10, and 1:15: add 1 / 3 of the washing water to the first stage of washing, and add a certain amount neutralize the acid to pH 4.5-5.5, and filter; add 1 / 3 of the washing water to the second and third sections respectively, and filter and squeeze the material dry. Collect the black liquor and the filtrate of the third stage separately, and a...

Embodiment 2

[0026] Example 2 Cellulase hydrolysis of washed corn stalks at a substrate concentration of 5% (w / v)

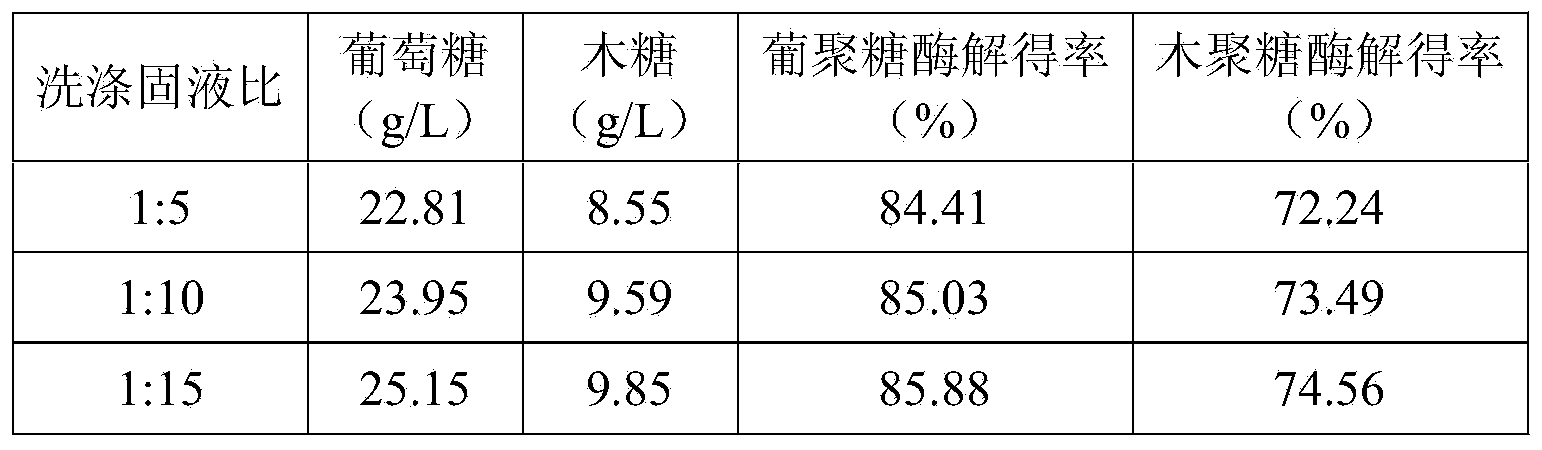

[0027]Take by weighing respectively the water-washed corn stalks of Example 1 whose absolute dry weight is 2.50g in three 250mL conical flasks, add 1mol / L citric acid buffer solution 2.5mL in each conical flask, and the cellulase consumption is 13.94 FPIU / g green liquid pretreatment corn stalk (25FPIU / g dextran, cellulase activity: β-glucosidase activity: xylanase activity=1:1.15:6.61) in each Erlenmeyer flask, add corresponding For enzyme, add an appropriate amount of distilled water to each Erlenmeyer flask so that the total volume of water in the enzymolysis system is 50mL, mix the reaction system thoroughly with a glass rod, cover it, and place it in a constant temperature shaker at 150 rpm and 50°C. Enzymolysis for 48h. After the hydrolysis, the hydrolyzate was centrifuged at 4000 rpm for 10 min, and the supernatant was taken to measure the concentration of glucose and...

Embodiment 3

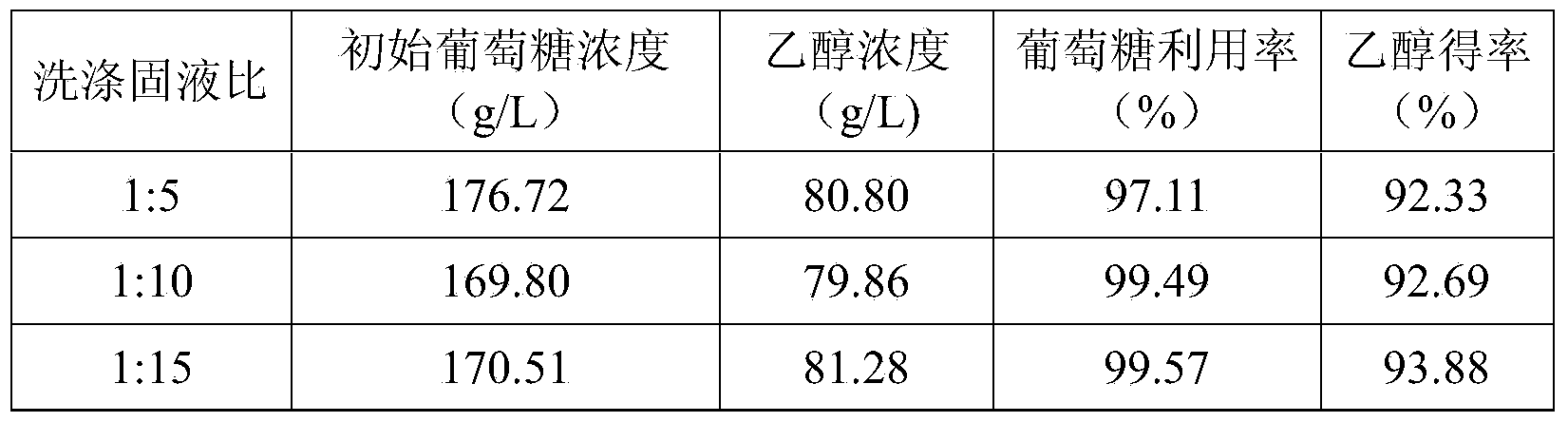

[0031] Example 3 Concentration and ethanol fermentation of hydrolyzed sugar solution

[0032] Weigh the water-washed corn stalks of Example 1 with a dry weight of 25 g at a substrate concentration of 5% (w / v), and the amount of cellulase is 13.94 FPIU / g water-washed corn stalks (25 FPIU / g dextran, cellulose Enzyme activity: β-glucosidase activity: xylanase activity=1:1.15:6.61), carry out enzymatic hydrolysis under the condition of pH4.8-5.0, cover the cover after fully mixing the reaction system with glass rod, at 150 RPM, 50°C constant temperature shaker for 48h. After solid-liquid separation, the supernatant was concentrated on a rotary evaporator at 70°C and 160mbar to a glucose concentration of 150-200g / L.

[0033] Take 100mL of the above-mentioned concentrated sugar solution in a 250mL conical flask, add 0.024g urea, 0.008g magnesium sulfate, 0.008g zinc sulfate, 1.0g active Saccharomyces cerevisiae dry powder, and cover with a rubber stopper (insert a needle on the rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com