Technology for recycling platinum and palladium from acid solution containing low concentration of platinum family precious metals by adopting reducing precipitation method

An acidic solution and precious metal technology, applied in the field of metallurgy, can solve the problems of high cost, low platinum and palladium content, toxicity and carcinogenicity, etc., and achieve the effect of low cost, high reduction efficiency and easy filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

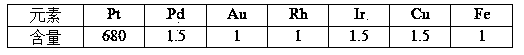

[0022] The composition of the acid feed solution containing platinum and palladium is shown in Table 1 below (mg / L)

[0023]

[0024] Take 5 mL of the platinum-palladium-containing acid feed solution composed in Table 1, and slowly add 6 mol L -1 Sodium hydroxide solution to pH = 1.0, add 0.21g sodium formate solid (30g / L in the total volume of the pH-adjusted feed liquid), heat in a boiling water bath for 1h, cool to room temperature, and stand for 12 hours; add 0.03 mL 10% sodium borohydride-10% sodium hydroxide mixed solution, then keep warm at 50°C~60°C for 10min, cool down to room temperature naturally, add 0.025mL0.01% polyacrylamide (the concentration of polyacrylamide in the system is 0.3 mg / L), placed for 12 hours, centrifugal sedimentation, platinum -1 1mL of sulfuric acid, reacted in a water bath at 50°C~60°C for 30min, centrifuged to settle, washed the precipitate with water three times; then added 2mL of 4mol·L -1 Hydrochloric acid-2% sodium chlorate mixture, ...

Embodiment 2

[0026] The composition of platinum-containing palladium acid feed solution is the same as in Example 1.

[0027] Take 100 mL of platinum-palladium-containing acidic feed solution, slowly add 6 mol L -1 sodium hydroxide solution to pH = 1.0, add 3.6g of sodium formate solid (concentration in the feed liquid: 30g / L), heat in a boiling water bath for 1h, cool to room temperature, and let stand for 12 hours; add 0.5mL of 10% sodium borohydride-10 % sodium hydroxide mixture, then keep it warm at 50°C~60°C for 10min, cool to room temperature naturally, let stand for 12h, then add 0.2mL0.01% polyacrylamide (the concentration of polyacrylamide in the system is 0.2mg / L) , centrifugal sedimentation, platinum -1 5mL of sulfuric acid, reacted in a water bath at 50°C~60°C for 30min, centrifuged to settle, washed the precipitate with water, and then added 5mL of 6mol·L -1 Hydrochloric acid-2% sodium chlorate mixed solution, react at 65~75°C for 20 minutes to dissolve all the precipitates, ...

Embodiment 3

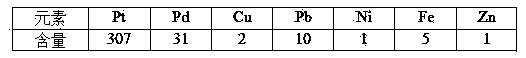

[0029] The composition of the acid feed solution containing platinum and palladium is shown in the following table 2 (mg / L)

[0030]

[0031] Take 5 mL of platinum-palladium-containing acidic feed solution, slowly add 6 mol L -1 Sodium hydroxide solution to pH = 1.0, add 0.21g sodium formate solid (concentration in the feed liquid is 30g / L), heat in boiling water bath for 1h, cool to room temperature, and let stand for 12 hours; add 0.03mL 10% sodium borohydride- 10% sodium hydroxide mixed solution, then keep warm at 50°C~60°C for 10min, cool down to room temperature naturally, then add 0.025mL 0.01% polyacrylamide (the concentration of polyacrylamide in the system is 0.3mg / L), place After 12 hours, centrifuge to settle, and the platinum in the supernatant of the precipitate is less than 0.5 mg / L, and the palladium is less than 0.1 mg / L. Add 1mol·L to the sediment slurry -1 2mL of sulfuric acid, reacted in a water bath at 50°C~60°C for 20min, centrifuged to settle, washed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com