Preparation method of graphene composite current collector

A graphene composite and current collector technology, applied in capacitor parts and other directions, can solve problems such as large specific surface area, easy agglomeration, integrity of graphene current collectors, and film-forming effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

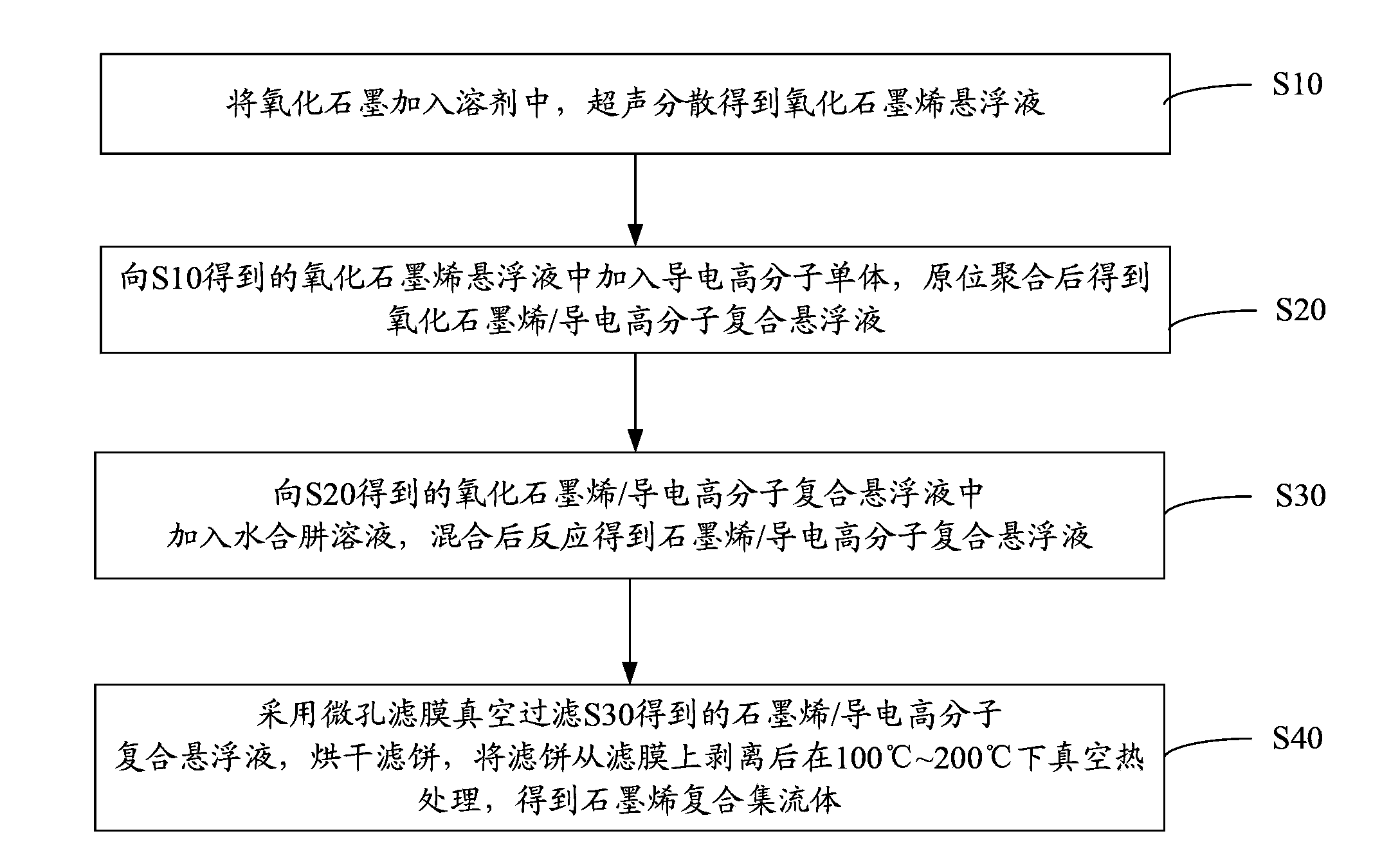

[0027] Such as figure 1 The preparation method of the graphene composite current collector of one embodiment shown, comprises the steps:

[0028] S10, adding graphite oxide into the solvent, and ultrasonically dispersing to obtain a graphene oxide suspension.

[0029] The time for ultrasonic dispersion can be 1h~2h, subject to obtaining the graphene oxide suspension.

[0030] The concentration of the obtained graphene oxide suspension can be 0.1 mg / ml-5 mg / ml.

[0031] The solvent can be one of ethanol, isopropanol, propanol or carbon tetrachloride.

[0032] S20, adding a conductive polymer monomer to the graphene oxide suspension obtained in S10, and obtaining a graphene oxide / conductive polymer composite suspension after in-situ polymerization.

[0033] The conductive polymer monomer can be pyrrole monomer, aniline monomer or thiophene monomer.

[0034] The mass ratio of graphene oxide and conductive polymer monomer can be 1:1~5:1.

[0035] In situ polymerization to obt...

Embodiment 1

[0052] Add graphite oxide into the ethanol solution for ultrasonic dispersion for 1 hour to obtain a 0.1mg / ml graphene oxide suspension, then add analytically pure pyrrole monomer (the mass ratio of pyrrole monomer to graphene oxide is 1:2), continue Sonicate for 10 min to form a stable suspension. At 0°C, slowly dropwise add an aqueous solution of ferric chloride with a concentration of 0.5 mol / L (the molar ratio of ferric chloride to pyrrole monomer is 1:1) to the stable suspension above, and stir for 4 hours to make pyrrole single A polymerization reaction occurs in the body to obtain a graphene oxide / polypyrrole composite suspension.

[0053] To the obtained graphene oxide / polypyrrole composite suspension, add a hydrazine hydrate solution with a mass fraction of 85% (the mass ratio of hydrazine hydrate and graphene oxide is 1:10), and react at a temperature of 100°C for 12 hours to obtain graphite ene / polypyrrole composite suspension.

[0054] The graphene / polypyrrole co...

Embodiment 2

[0058] Add graphite oxide into the isopropanol solution for ultrasonic dispersion for 2 hours to obtain a 1 mg / ml graphene oxide suspension, then add analytically pure aniline monomer (the mass ratio of aniline monomer to graphene oxide is 1:1), Continue to sonicate for 20 minutes to form a stable suspension. Add ammonium persulfate and an alcoholic solution of concentrated hydrochloric acid with a mass fraction of 37% to the stable suspension at -5°C sequentially (the molar ratio of ammonium persulfate to aniline monomer is 1 : 1), stirring for 12 hours, so that the aniline monomer undergoes a polymerization reaction to obtain a graphene oxide / polyaniline composite suspension.

[0059] To the obtained graphene oxide / polyaniline composite suspension, add a hydrazine hydrate solution with a mass fraction of 85% (the mass ratio of hydrazine hydrate and graphene oxide is 4:10), and react at a temperature of 80°C for 24 hours to obtain graphite olefin / polyaniline composite suspens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com