Composite expanding agent for cement-based non-shrinkage grouting material

A composite expansion agent, non-shrinkage technology, applied in the field of composite expansion agent, can solve the problems of ettringite expansion source unable to provide plastic expansion, unable to obtain expected use effect, low compressive strength of grouting material, etc., to achieve high expansion rate, Efficient plastic expansion and short stability period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation of embodiment one calcium aluminate powder

[0035] Using the raw material ratio of 0.68 tons of bauxite, 0.66 tons of limestone, and 0.26 tons of coal, the raw material with a fineness of 0.08mm sieve 2 o 3 52.67%, CaO32.69%, SiO 2 9.02%, Fe 2 o 3 1.68%, TiO 2 2.97%, MgO0.74%, loss on ignition 0.23% of 1 ton of calcium aluminate powder, its CA 2 Content 32%, CA content 17.3%, CA 2 / CA is 1.85, and the rest is inactive mineral C 2 AS, CT, C 2 F et al.

Embodiment 2

[0036] The preparation of embodiment two composite expansion agent

[0037] According to the weight ratio shown in Table 1, each component is sequentially added into the dry powder mixer, and the composite expansion agent can be obtained through thorough and uniform mixing.

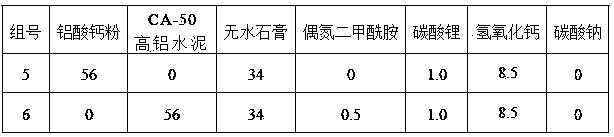

[0038] Table 1 The weight ratio of each component of composite expansion agent

[0039] Group No Calcium aluminate powder Anhydrite Azodicarbonamide lithium carbonate Calcium hydroxide Sodium carbonate 1 56 34 0.5 1.0 8.5 0 2 60 25 0.4 1.0 13.6 0 3 50 35 0.7 0.5 13.1 0.7 4 52 40 0.7 0.7 6.6 0

Embodiment 3

[0044] The preparation of embodiment three grouting material

[0045] The composite expansion agent prepared in Example 2 and the expansion agent prepared in Comparative Example 1 were used to prepare grouting materials respectively. The basic composition of the grouting material is: P.Ⅱ52.5 cement, mortar ratio 1:1.375, the amount of naphthalene-based water reducer is 1.3% of the cement amount, based on the total amount of grouting material, adding 0.4~0.6% P803 organosilicon defoamer, 0.4%~0.6% sodium gluconate and 0.4%~0.6% tartaric acid or citric acid are used as retarders, and each group of expansion agents is mixed into cement according to the different weight ratios in Table 2.

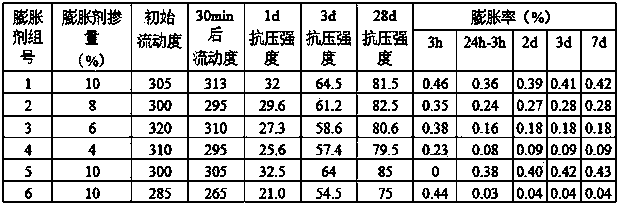

[0046] According to the experimental method described in GB / T50448-2008 "Technical Specifications for the Application of Cement-based Grouting Materials", the technical performance of the grouting materials in each example is measured by using a water-material ratio of 0.13, as shown in Table 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com