Preparation method of temperature-resistant anti-salt anti-shearing nano-polymer

A nano-polymer, temperature-resistant and salt-resistant technology, applied in the field of water-soluble polymer synthesis, can solve the problems of low molecular weight of branched polymers, difficult to apply in a wide range, difficult to apply on a large scale, etc., and achieves high molecular weight, product post-processing Simple, easy-to-store effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

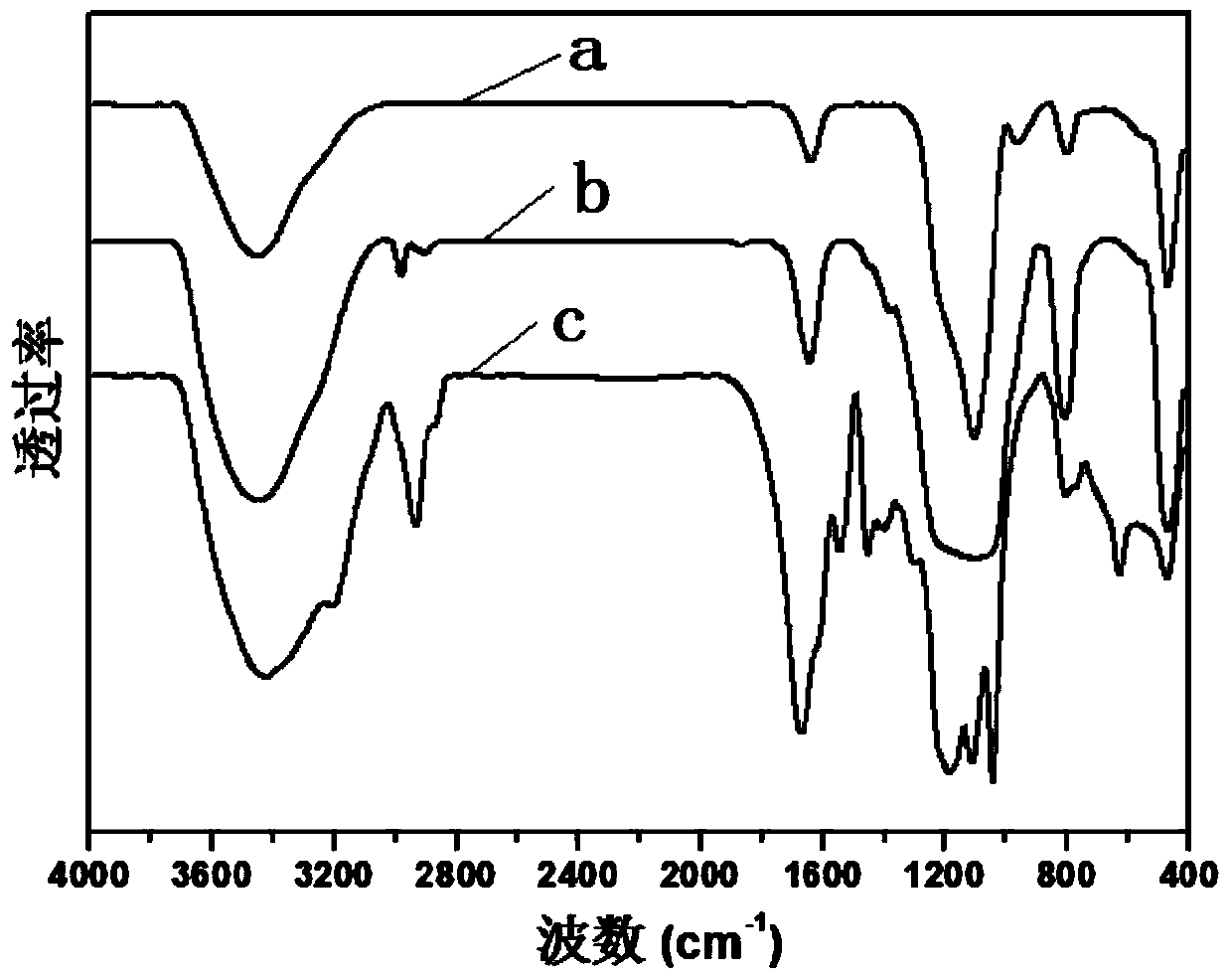

Image

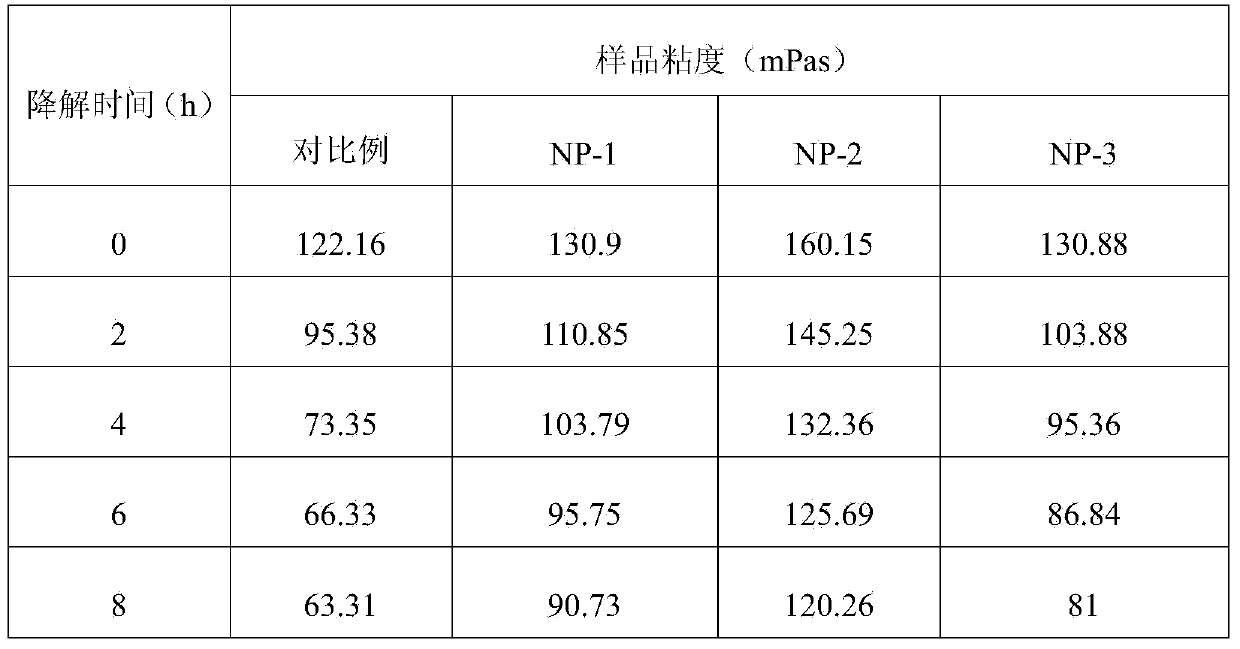

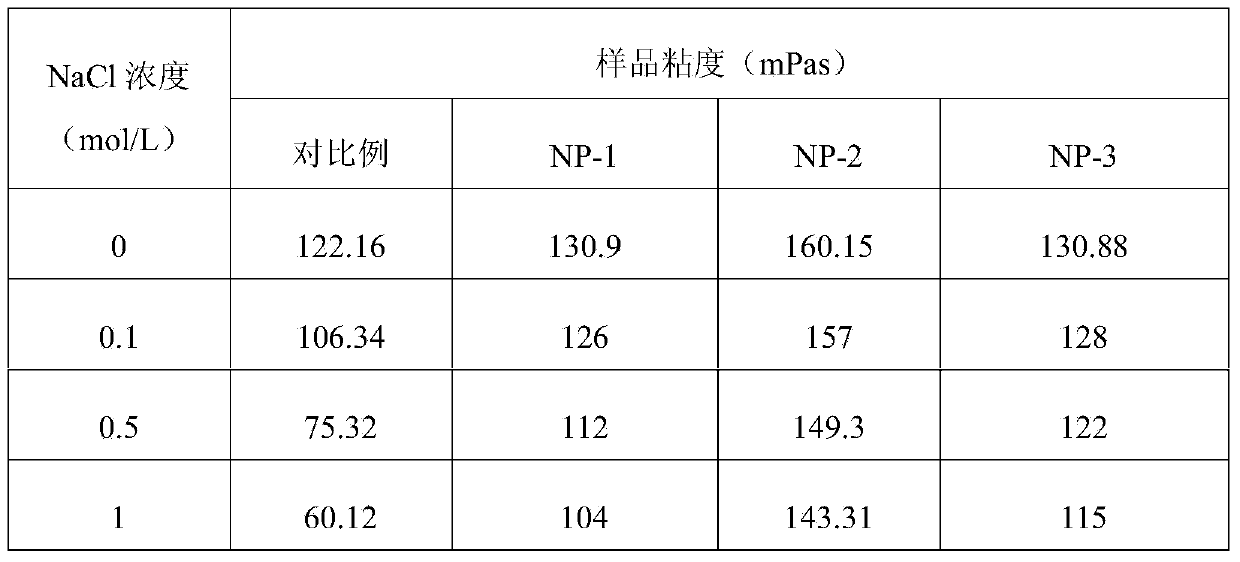

Examples

Embodiment 1

[0046] A method for preparing a temperature-resistant, salt-resistant and shear-resistant nanopolymer, comprising the following steps:

[0047] (1) Measure 50ml of water and add it to a four-necked bottle equipped with a stirrer, nitrogen pipe, vent pipe and thermometer, weigh 1.4419g of sodium lauryl sulfate into the water, and stir at room temperature until completely dissolved to form a stable emulsion;

[0048] (2) Add 1.4216g monomeric acrylamide and 1.295g monomeric 2-acrylamido-2-methylpropanesulfonic acid to the emulsion prepared in step (1), stir at room temperature until completely dissolved; weigh 0.05g A171 Add nano-silica to the above mixing system, and stir until dissolved at room temperature;

[0049] (3) Use sodium hydroxide and hydrochloric acid to adjust the pH of the system prepared in step (2) to 7.5; use a pipette to measure 60 μl of ammonium persulfate solution with a concentration of 1mol / L and add it to the above mixture, stir and dissolve The bottle i...

Embodiment 2

[0057] As described in Example 1, the difference is that in step (2) the amount of A171 nano-silica added is changed to 0.10 g to obtain 1.384 g of temperature-resistant, salt-resistant and shear-resistant nanopolymerization, which is denoted as NP-2. The molecular weight is 4.73×10 6 g / mol.

Embodiment 3

[0059] As described in Example 1, the difference is that in step (2) the amount of A171 nano-silica added is changed to 0.15g, and 1.274g of temperature-resistant, salt-resistant, and shear-resistant nanopolymerization is obtained, which is denoted as NP-3. The molecular weight is 4.28×10 6 g / mol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com