Upconversion nanocrystalline/titanium dioxide composite nanomaterial and preparation method thereof

A technology of composite nanomaterials and titanium dioxide, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of low overall utilization efficiency of infrared light, large overall size of composite materials, and poor luminous performance and other issues to achieve the effect of light weight, small size and high up-conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach ( 1

[0040] An up-conversion nanocrystal / titanium dioxide composite nanomaterial, its chemical expression is: NaYF4:Yb, TmSiO2TiO 2 ; Among them, "" means wrapping.

[0041] A preparation method for upconversion nanocrystal / titanium dioxide composite nanomaterial, comprising the following steps:

[0042] A. High-quality hexagonal NaYF with a size of 20nm 4 : Yb, Tm nanocrystals are the core, and a layer of silica shell is coated on the surface:

[0043] a. In a 10ml glass bottle, mix cyclohexane, IGEPAL CO-520 and ammonia water at a volume ratio of 500:25:4, and shake until clear;

[0044] b. High quality hexagonal NaYF with a size of 20nm 4 : Yb, Tm nanocrystals are dissolved in cyclohexane, the concentration is 0.1 moles per liter, then 200 microliters of the solution is added to the mixed solution formed in the previous step, and shaken evenly;

[0045] c. Add 200 microliters of tetraethyl orthosilicate cyclohexane solution with a concentration of 0.5 moles per liter to the...

specific Embodiment approach ( 2

[0053] On the basis of the specific embodiment (1), only the added amount of diisopropyl di(acetylacetonato)titanate is replaced by 4.5 ml.

specific Embodiment approach ( 3

[0055] On the basis of the specific embodiment (1), only the added amount of diisopropyl di(acetylacetonato)titanate is replaced by 18 ml.

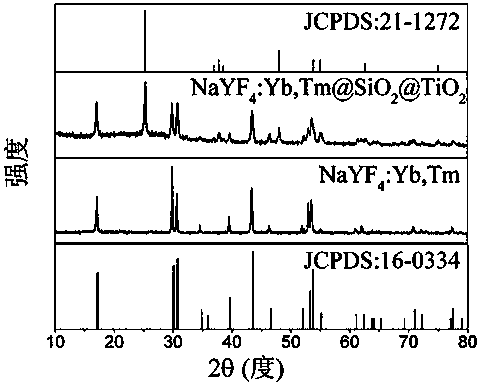

[0056] The data measured under the X-ray powder diffractometer in the above examples are as follows: figure 1 shown. figure 1 The X-ray diffraction data show that the crystallinity of the uncoated sodium tetrafluoroyttrium nanoparticle crystals is very high, which completely corresponds to the peak of the powder crystal diffraction card JCPDS: 16-0334 of the Joint Committee on X-ray Powder Diffraction Standards, indicating that the tetrafluoroethylene used The sodium yttrium fluoride sample is a pure phase without impurities. The product coated with titanium dioxide is annealed and the X-ray powder diffraction data obtained show that in addition to sodium tetrafluoroyttrium crystals, there is anatase titanium dioxide in the product (JCPDS: 21-1272).

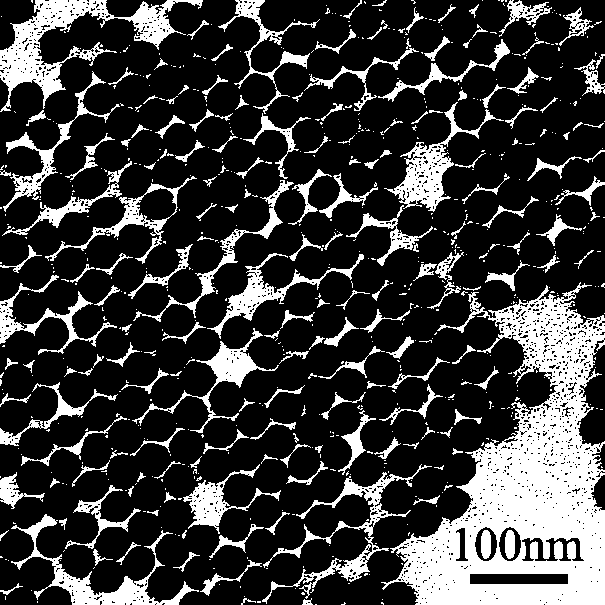

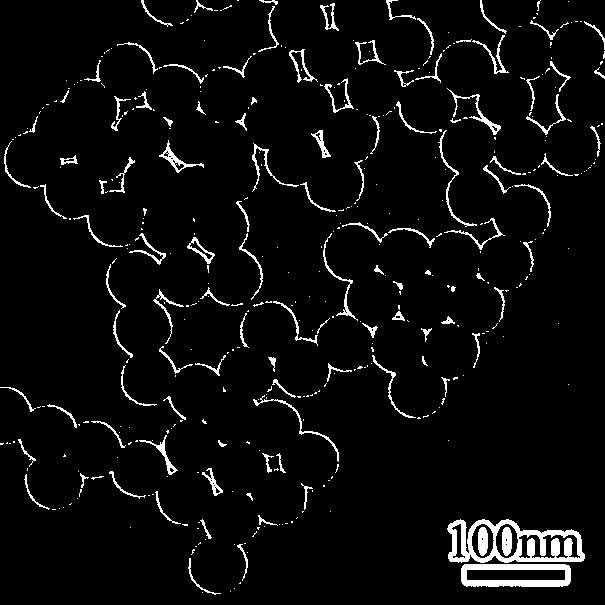

[0057] Figure 2~Figure 6 It is the data obtained by characterizing the samples synth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com