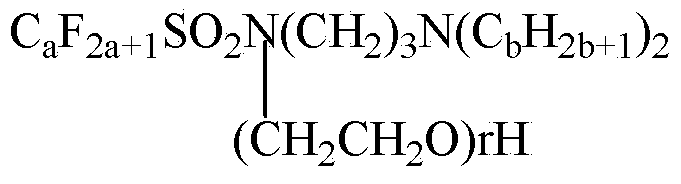

Preparation method of fluorine-containing non-ionic surface active agent and application

A surfactant, non-ionic technology, applied in the field of preparation of fluorine-containing surfactants, can solve the problems of refractory degradation, high bioaccumulation and toxicity to multiple organs of the human body, and achieves low cost, high practical value, high The effect of surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Preparation of nonionic fluorine-containing ionic surfactants.

[0021] Take 0.1mol perfluorobutylsulfonyl fluoride and 0.1mol N,N'-diethyl-1,3-propanediamine for amidation reaction, and use dichloromethane as solvent to obtain intermediate 1 (N-[3- (diethylammonia)-propyl] perfluorobutylsulfonamide), intermediate 1 uses acetone as solvent, reacts with ethylene oxide or chloroethanol to obtain intermediate 2 (N'-3-(diethyl )-propyl-(N-perfluorobutylsulfonyl-N-epoxy)-amine), intermediate 2 uses acetone as solvent to carry out ring-opening reaction with ethylene oxide to obtain non-ionic fluorine-containing surface active agent.

Embodiment 2

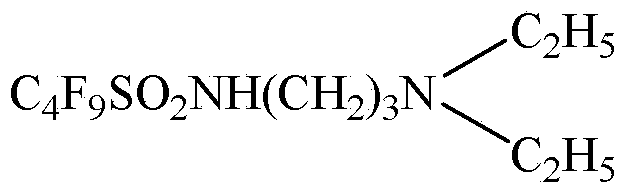

[0023] The synthesis of N-[3-(diethylamino)-propyl] perfluorobutylsulfonamide in embodiment 1

[0024] The synthesis process is as follows: In a three-neck round bottom flask equipped with a magnet, add an appropriate amount of dichloromethane, 0.03mol triethylamine and 0.1mol N,N′-diethyl-1,3-propanediamine, ice-water bath 0.1mol of perfluorobutylsulfonyl fluoride was added dropwise, and then reacted for 8 hours, and then rotary steamed to obtain a yellow oil, which was recrystallized with acetone to obtain a white crystal, the chemical expression of which was:

[0025]

[0026] MS(412.09); F 19 NMR: -85.952, -115.049, -123.705, -128.212; H 1 NMR: 2.322 (6H, -CH 3 ),3.502(2H,-CH 2 -),2.617(2H,-CH 2 -,),1.766(2H,-CH 2 -), 3.488 (-NH).

Embodiment 3

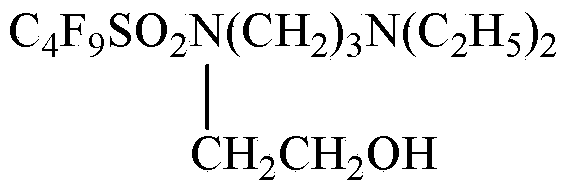

[0028] Synthesis of N'-3-(diethyl)-propyl-(N-perfluorobutylsulfonyl-N-epoxy)-amine in Example 1

[0029] The synthesis process is as follows: In a three-neck round bottom flask equipped with a magnet, add an appropriate amount of acetone, 0.1mol N-[3-(diethylammonia)-propyl]perfluorobutylsulfonamide, add a small amount of NaOH to adjust the pH From 7 to 8, add 0.1mol ethylene oxide dropwise in an ice-water bath, and then react for 6 hours. After rotary steaming, continue to bake to obtain a light yellow viscous substance. The product expression is:

[0030]

[0031] MS(456.11);H 1 NMR: 3.60(2H,-CH 2 -), 2.74(2H,-CH 2 -), 2.55(2H,-CH 2 -,), 2.36(2H,-CH 2 -), 2.40(4H,-CH 2 -), 1.51(2H,-CH 2 -),1.02(6H,-CH 3 ), 2.0 (-OH).

[0032] Minimum surface tension: 19.8 mN / m, CMC value 4 / 1000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Minimum surface tension | aaaaa | aaaaa |

| Minimum surface tension | aaaaa | aaaaa |

| Minimum surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com