Method for recovering polyol from wastewater

A polyol and wastewater technology, applied in chemical instruments and methods, preparation of organic compounds, production of bulk chemicals, etc., can solve the problems of high energy consumption, large energy consumption, inconspicuousness, etc., and achieves pollution reduction and high added value. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The wastewater comes from the process of hydrogen peroxide oxidation to produce propylene oxide, that is, the HPPO process, which contains propylene glycol with a mass fraction of 4.3%.

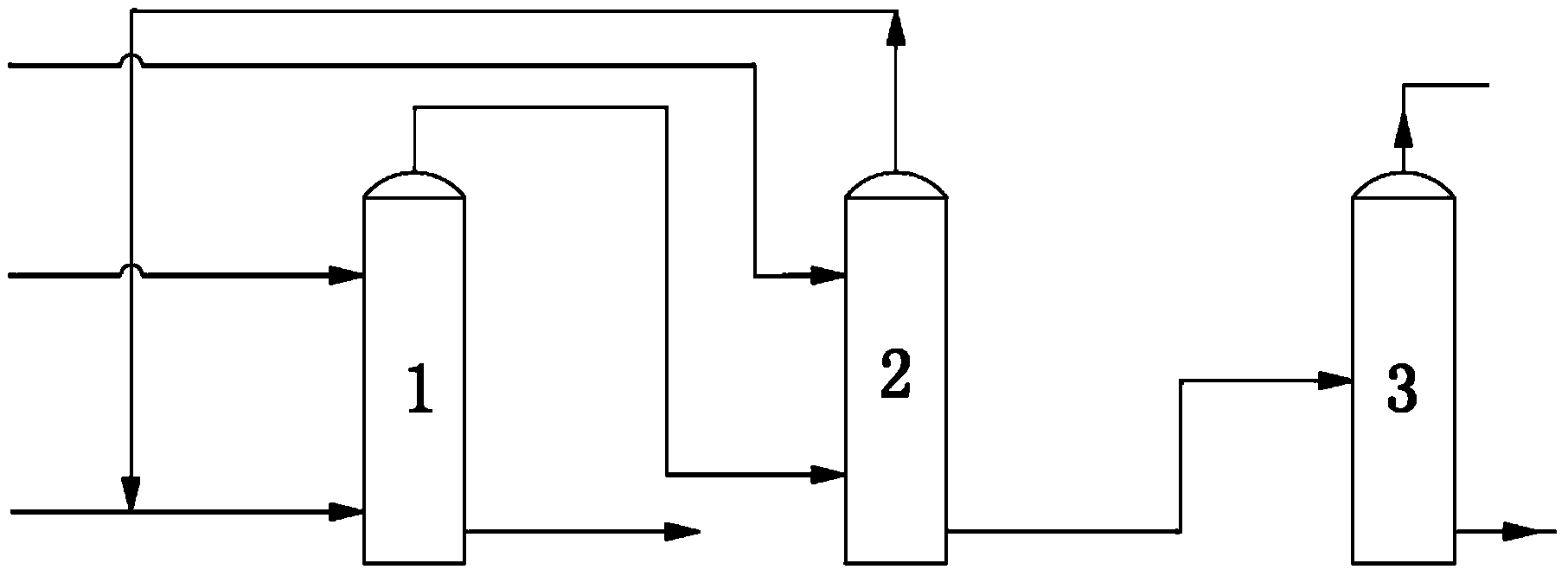

[0038] The equipment includes three packed towers: reactive distillation tower, hydrolysis tower and refining tower.

[0039] The reactive distillation column has 30 trays, and acetaldehyde is fed from the 27th tray, and the feed rate is 6221Kg / h (wherein the supplementary acetaldehyde feed is 40Kg / h, and the recycled acetaldehyde is 6181Kg / h) , the wastewater containing propylene glycol is fed from the third tray (feed composition: hydrogen peroxide H2O20.4866Kg / h, H2O57999.886Kg / h, propylene glycol C3H8O22622.4743Kg / h, propylene glycol monomethyl ether C4H10O345.0981Kg / h), reflux The ratio is 1.05, the output of the reactive distillation tower is 10694.317Kg / h, the operating pressure is 0.99atm, and the pressure drop of each layer is 0.02KPa.

[0040] The strongly acidic cationic re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com