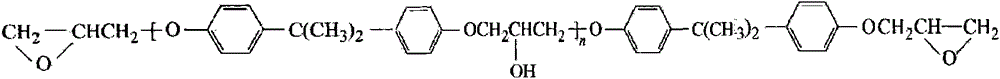

Three-stage linking material composite resin, ink and preparation method thereof

A composite resin and bonding material technology, used in inks, applications, household appliances, etc., can solve problems such as high skin irritation, slow curing speed, soil damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0159] A preparation method of a biodegradable UV-curable ink, comprising the following steps:

[0160]Step 1. Mixing hydroxyl-containing alkyl (meth)acrylate and diisocyanate, so that the hydroxyl group of the hydroxyl-containing alkyl (meth)acrylate reacts with the isocyanate group of the diisocyanate, wherein the isocyanate The molar amount is greater than the molar amount of the hydroxyl group of the (meth)acrylic acid alkyl ester containing the hydroxyl group, and then the (meth)acrylic acid alkyl ester monomer that does not contain the hydroxyl group is added, so that the (methyl) Alkyl acrylate and the alkyl (meth)acrylic acid monomer containing hydroxyl group undergo a radical polymerization reaction to generate a urethane / (meth)acrylate copolymer with isocyanate groups;

[0161] Step 2, the water-soluble starch is reacted with diisocyanate, wherein the molar weight of the isocyanate group is greater than the molar weight of the hydroxyl group of the hydroxyl-containin...

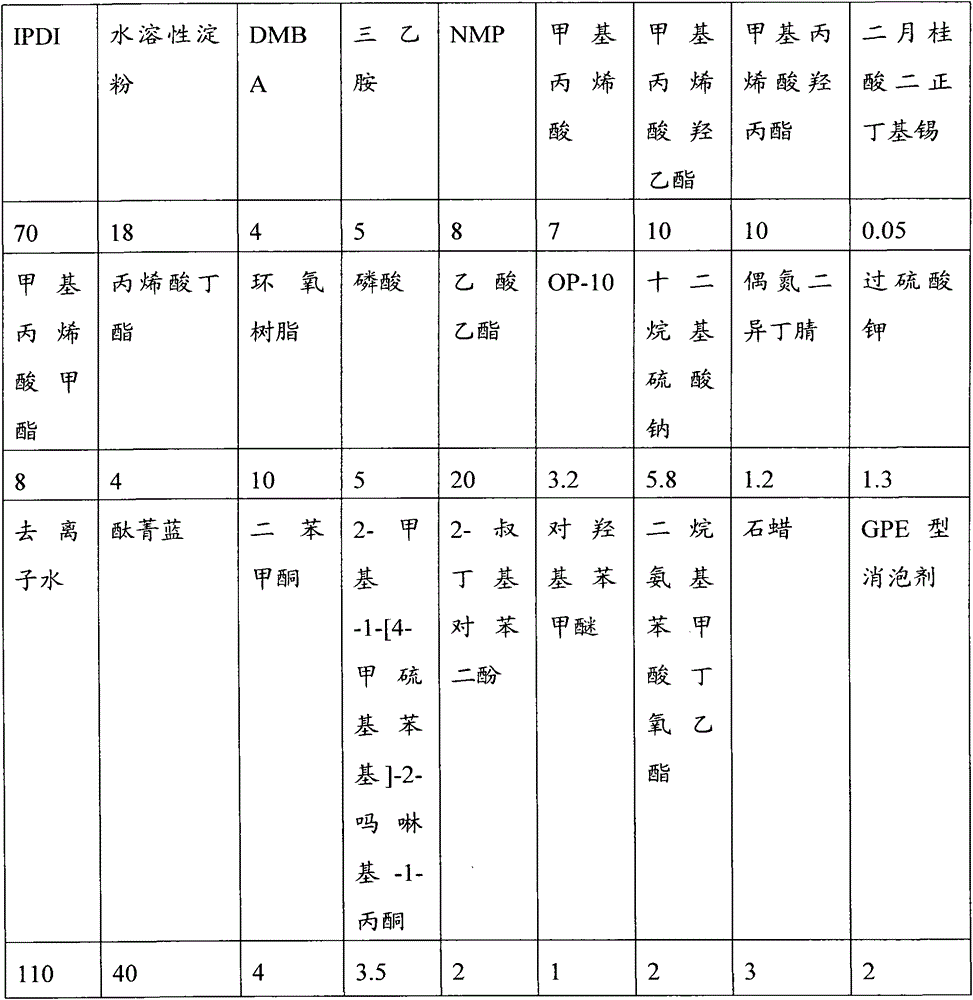

Embodiment 1

[0199] a. Add 20g of isophorone diisocyanate into a clean four-neck flask with reflux condenser, thermometer and stirring device, and add 10g of hydroxyethyl methacrylate and 10g of hydroxypropyl methacrylate to the flask Mixture, use stirring device to open in this process and keep mechanical stirring state to make isophorone diisocyanate and methacrylate functional mixed monomer (the mixed monomer refers to hydroxyethyl methacrylate and hydroxypropyl methacrylate Esters) were kept in a uniformly mixed state, and stirred in a constant temperature water bath at 80°C for 3 hours to undergo a polymerization reaction;

[0200] The reaction formula of this step is mainly: -NCO+HO-→-NH-COO-

[0201] b. Mix 3.2g of OP-10 and 5.8g of sodium lauryl sulfate in 10g of deionized water, and then continuously drop the deionized water into the reaction system of step a, and stir and mix for 10 minutes 8g of methyl methacrylate, 4g of butyl acrylate and 7g of methacrylic acid mixed solution...

Embodiment 2

[0222] a. Add 39g of isophorone diisocyanate into a clean four-necked flask with reflux condenser, thermometer and stirring device. According to the principle of gradual polymerization reaction, add 19g of water-soluble starch to the reaction system and keep the temperature at 80°C. After mixing and stirring in a water bath for 2 hours, add 0.05g of di-n-butyltin dilaurate as a catalyst to fully react the water-soluble starch and diisocyanate for 30 minutes; reduce the temperature of the constant temperature water bath to 60°C, and add 4.5g of dimethylolbutyl Acid and 8g of N-methylpyrrolidone, stir and react at 60°C for 10 minutes, then raise the temperature of the water bath to 70°C and continue to stir and react for 10 minutes, then adjust the temperature of the constant temperature water area to 80°C and stir for 2 hours to generate terminal isocyanate groups Hydrophilic polyurethane prepolymer;

[0223] The reaction formula of this step is mainly: -NCO+HO-→-NH-COO-

[02...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| cloud point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com