Preparation method of cubic micro-nano composite structure cobalt manganese oxide denitration catalyst

A micro-nano composite structure, cobalt manganese oxide technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of difficult to obtain high-performance denitration catalysts. , It is difficult to atomically disperse and affect the active components, and achieve the effect of increasing adsorption active sites, good low-temperature denitration activity, and low experimental requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

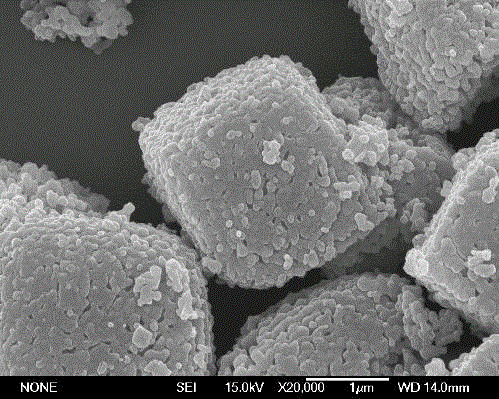

[0025] Prepare a mixed brine solution with a concentration of 0.014mol / L cobalt nitrate and manganese sulfate, and make the atomic ratio of cobalt and manganese 1:2. Add 0.05 times the volume of the mixed aqueous solution in dehydrated alcohol and ammonium bicarbonate aqueous solution with a concentration of 0.014mol / L to the above solution in sequence. The resulting mixture was stirred and reacted at 50° C., kept for 9 hours, cooled to room temperature naturally, washed and dried to obtain cobalt-manganese composite carbonate. The dried cobalt-manganese composite carbonate was calcined in the air at a calcination temperature of 550°C, a heating rate of 2°C / min, a heat preservation of 5h, and natural cooling to room temperature to obtain the final product. The microscopic appearance of the catalyst was as follows: figure 1 As shown, the size of the cubes is between 1-3 μm.

[0026] Test the catalytic activity of the above-mentioned catalysts: Sieve the prepared catalyst into...

Embodiment 2

[0028] Prepare a mixed brine solution with a concentration of 0.1mol / L cobalt sulfate and manganese nitrate, and make the atomic ratio of cobalt and manganese 1:1. Add 0.25 times the volume of the mixed aqueous solution of absolute ethanol and ammonium bicarbonate aqueous solution with a concentration of 0.001 mol / L to the above solution in sequence. The obtained mixed solution was stirred and reacted at 80° C., kept for 14 hours, cooled naturally to room temperature, washed and dried to obtain cobalt-manganese composite carbonate. The dried cobalt-manganese composite carbonate is calcined in the air at a calcination temperature of 600°C, a heating rate of 4°C / min, a heat preservation of 6h, and natural cooling to room temperature to obtain the final product.

[0029] Test the catalytic activity of the above-mentioned catalysts: Sieve the prepared catalyst into tablets, take 0.6g of 40-60 mesh particles, and put them into a fixed-bed quartz tube reactor to test the catalytic a...

Embodiment 3

[0031] Prepare a mixed brine solution with a concentration of 0.05mol / L cobalt acetate and manganese sulfate, and make the atomic ratio of cobalt and manganese 1:2. Add dehydrated ethanol 0.5 times the volume of the mixed aqueous solution and ammonium bicarbonate aqueous solution with a concentration of 0.02mol / L to the above solution in sequence. The obtained mixed solution was stirred and reacted at 40° C., kept for 24 hours, cooled to room temperature naturally, washed and dried to obtain cobalt-manganese composite carbonate. The dried cobalt-manganese composite carbonate is calcined in the air at a calcination temperature of 400°C, a heating rate of 4°C / min, a heat preservation of 12h, and natural cooling to room temperature to obtain the final product.

[0032] Test the catalytic activity of the above-mentioned catalysts: Sieve the prepared catalyst into tablets, sieve 0.4g of 60-90 mesh particles, and put them into a fixed-bed quartz tube reactor to test the catalytic ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com