Power-type nickel cobalt manganese acid lithium material as well as preparation method and application thereof

A nickel-cobalt lithium manganate, power type technology, applied in the field of power type nickel-cobalt manganate lithium manganate material and its preparation, can solve the problems of large particle size and difficult to control, achieve high specific capacity, reduce use cost and large surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

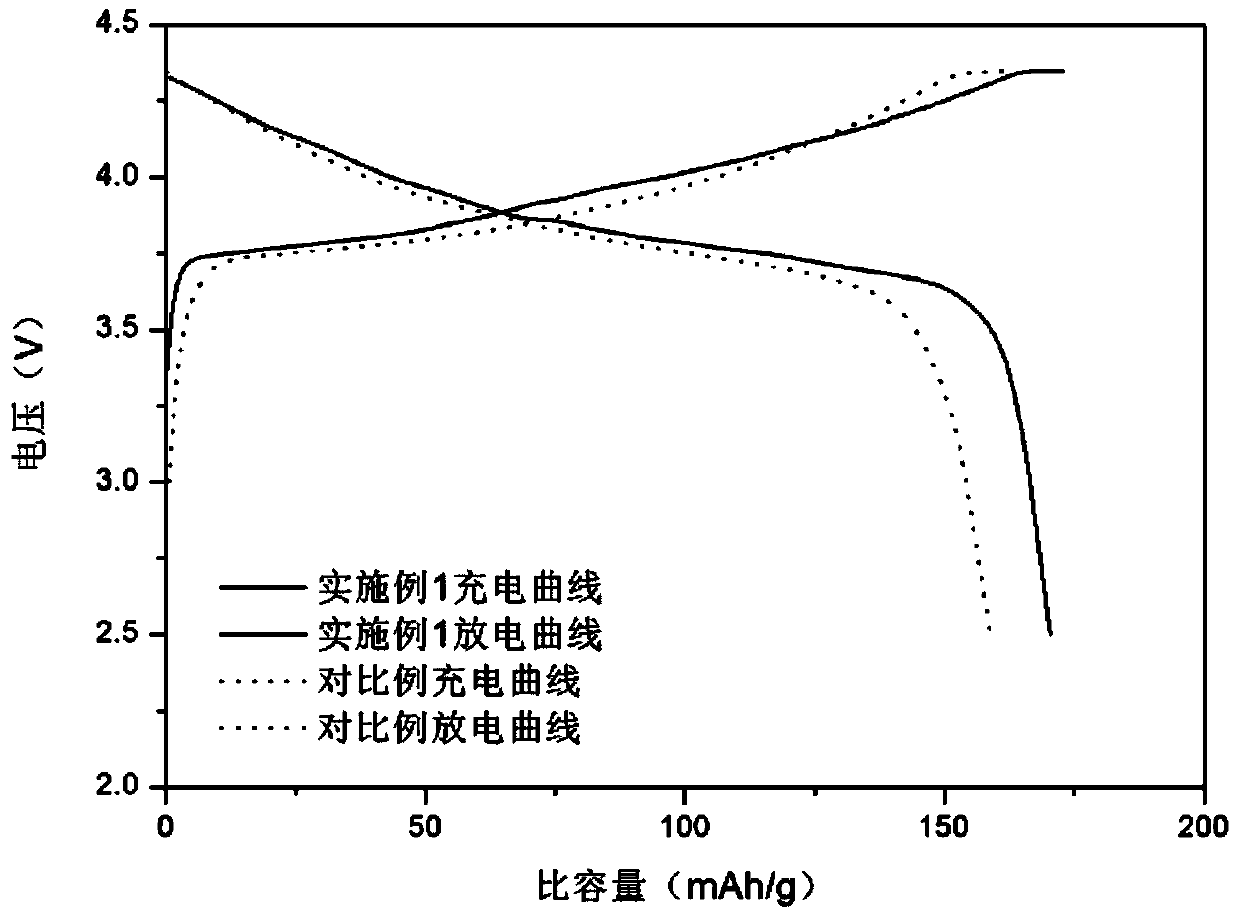

[0030] Embodiment 1: Preparation of dynamic nickel cobalt lithium manganese oxide material

[0031] (1) According to the concentration of lithium acetate 3mol / L, nickel acetate 1mol / L, cobalt acetate 1mol / L, manganese acetate 1mol / L, prepare 100mL mixed aqueous solution, add citric acid, so that the concentration of sodium citrate in the system is 3mol / L, Aging at 60° C. for 10 h until viscous and transparent, and continuing aging at room temperature to a viscosity of 2 Pa·S to obtain a sol precursor.

[0032] (2) Put the sol into a syringe with a nozzle aperture of 500 μm, feed at a rate of 5mL / h, voltage 20kV, solidify distance between the nozzle and the collector 10cm, fill with N 2 Spin under the above conditions until the pressure is 0.3MPa to obtain gel fibers, and dry at 70°C for 1 hour.

[0033] (3) Place the xerogel fiber obtained in step (2) in a calciner, raise the temperature from room temperature to 300°C at 0.5°C / min in the air, keep it for 1h, and then raise th...

Embodiment 2

[0034] Embodiment 2: Preparation of dynamic nickel cobalt lithium manganese oxide material

[0035] (1) According to the concentration of lithium hydroxide 9mol / L, nickel hydroxide 2mol / L, cobalt hydroxide 2mol / L, manganese hydroxide 2mol / L, prepare 100mL mixed aqueous solution, add tartaric acid, so that the concentration of tartaric acid in the system is 4mol / L , aged at 65°C for 9h until viscous and transparent, and continued to age at room temperature to a viscosity of 2.5Pa·S to obtain a sol precursor.

[0036] (2) Put the sol into a syringe with a nozzle diameter of 500 μm, feed at a rate of 7.5mL / h, and a voltage of 30kV. 2 Spin under the above conditions until the pressure is 0.4MPa to obtain gel fibers, and dry at 70°C for 1 hour.

[0037] (3) Put the xerogel fiber obtained in step (2) in a calciner, in the air, raise the temperature from room temperature to 350°C at 1°C / min, keep it for 2h, then raise the temperature to 700°C at 3°C / min, Keep for 9 hours to obtain ...

Embodiment 3

[0038] Embodiment 3: Preparation of dynamic nickel cobalt lithium manganese oxide material

[0039] (1) According to the concentration of lithium carbonate 18mol / L, nickel carbonate 3mol / L, cobalt carbonate 3mol / L, manganese carbonate 3mol / L, prepare 100mL mixed aqueous solution, add oxalic acid to make the organic acid concentration in the system 5mol / L, at 70 Aging at ℃ for 8h until viscous and transparent, and continuing aging at room temperature until the viscosity is 3Pa·S to obtain the sol precursor.

[0040] (2) Put the sol into a syringe with a nozzle aperture of 500 μm, feed at a rate of 10 mL / h, and a voltage of 30 kV. The curing distance between the nozzle and the collector is 30 cm, and fill with N 2 Spin under the above conditions until the pressure is 0.5MPa to obtain gel fibers, and dry at 70°C for 1 hour.

[0041] (3) Place the xerogel fiber obtained in step (2) in a calciner, in the air, raise the temperature from room temperature to 400°C at 1°C / min, keep it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com