Wear-resistant and flame-retardant swash plate

A technology of swash plate and wear-resistant coating, which is applied in the direction of coating, pretreatment surface, mechanical equipment, etc., can solve the problems of increasing preparation difficulty, increasing social energy consumption, harmful social environment, etc., and achieves a simple and controllable preparation process, The spraying thickness is easy to control and the composition is reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

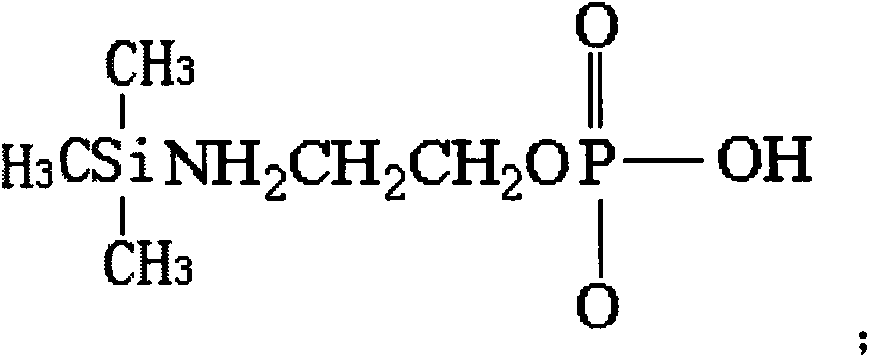

[0036] Synthesis Example 1 Synthesis of Silicon-containing Phosphate

[0037] Add 15mL trimethylbromosilane, 5ml diethanolamine, 30ml absolute ethanol and 2g potassium silanolate to the three-necked flask, reflux and stir for 5 hours, cool, and filter to obtain the liquid; add 2.5ml, 50ml of 85% phosphoric acid to the liquid Acetone and 1.2g of phosphorus pentoxide were heated to 60°C, stirred and reacted for 2 hours, the acetone was removed by distillation, and the obtained liquid was silicon-containing phosphate.

Synthetic example 2

[0038] Synthesis Example 2 Preparation of Composite Filler

[0039] Mix 380g of molybdenum disulfide and 100g of aluminum phosphate evenly, sinter at 500°C for 55min, and crush it into a powder with a particle size of 15-22μm, which is the composite filler.

Embodiment 1

[0041] A wear-resistant and flame-retardant swash plate, the preparation of which comprises the following steps:

[0042] (1) Preparation of Component A: In a nitrogen atmosphere, mix bisphenol A epoxy resin, maleic anhydride and ethylene glycol, react at 110° C. for 35 minutes, then add 5 drops of sulfuric acid with a concentration of 30%, and continue the reaction for 7 minutes Obtain an epoxy compound; then react the epoxy compound with bisphenol A cyanate at 150°C for 15 minutes to obtain Component A; wherein bisphenol A epoxy resin, maleic anhydride, ethylene glycol and bisphenol A cyanide The mass ratio of acid ester is 0.4: 1: 1.5: 1.5;

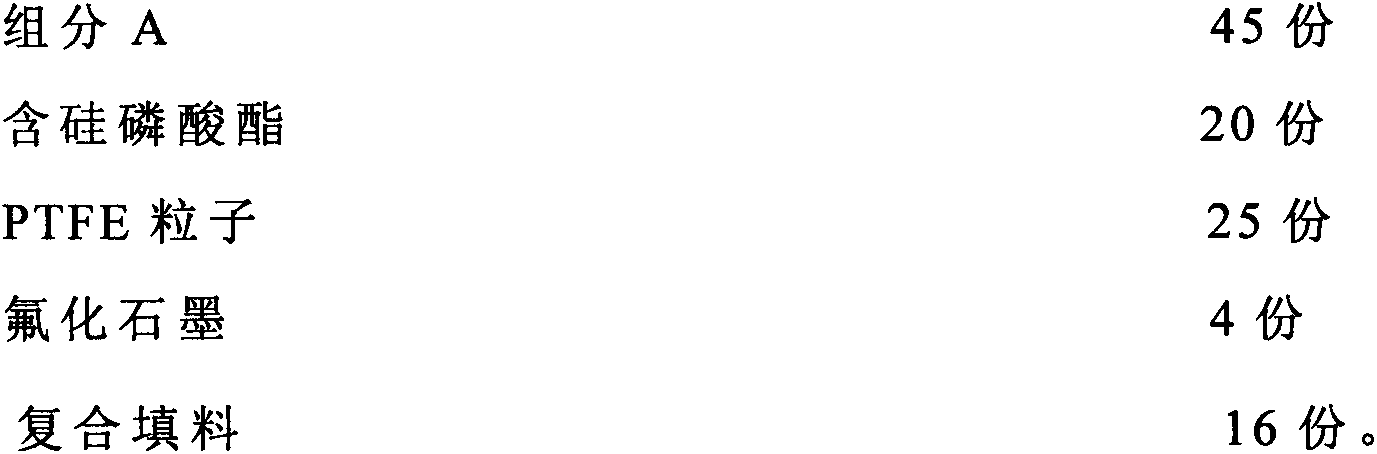

[0043](2) preparation of wear-resistant coating: dissolving component A in acetone to obtain mass concentration is the acetone solution of component A of 30%; then silicon-containing phosphate, PTFE particles, fluorinated graphite and composite filler are mixed uniformly, A solid lubricant is obtained; finally, the acetone solution of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com