A kind of zirconium rare earth oxygen storage material and its preparation method

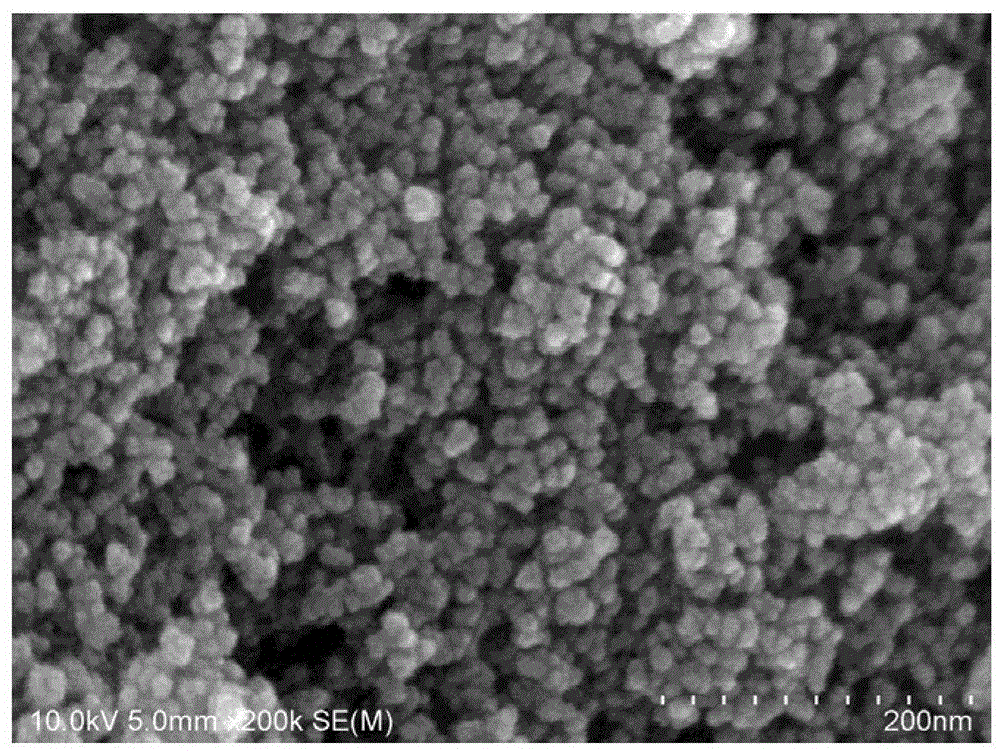

An oxygen storage material and rare earth technology, which is applied in the field of zirconium-based rare earth oxygen storage materials and their preparation, can solve the problems of low specific surface area, poor thermal stability, and difficulty in forming solid solutions of oxygen storage materials, and achieve high temperature stability and storage Oxygen performance improvement, high temperature stability, fine particle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Industrial zirconium oxychloride products (38.2% ZrO 2 ) 1000 g was dissolved in 5 liters of deionized water, and a small amount of hydrochloric acid was added, and then the zirconium and hafnium were purified and separated by MIBK (methyl isobutyl ketone) extractant to obtain a zirconium oxychloride stock solution with low hafnium content.

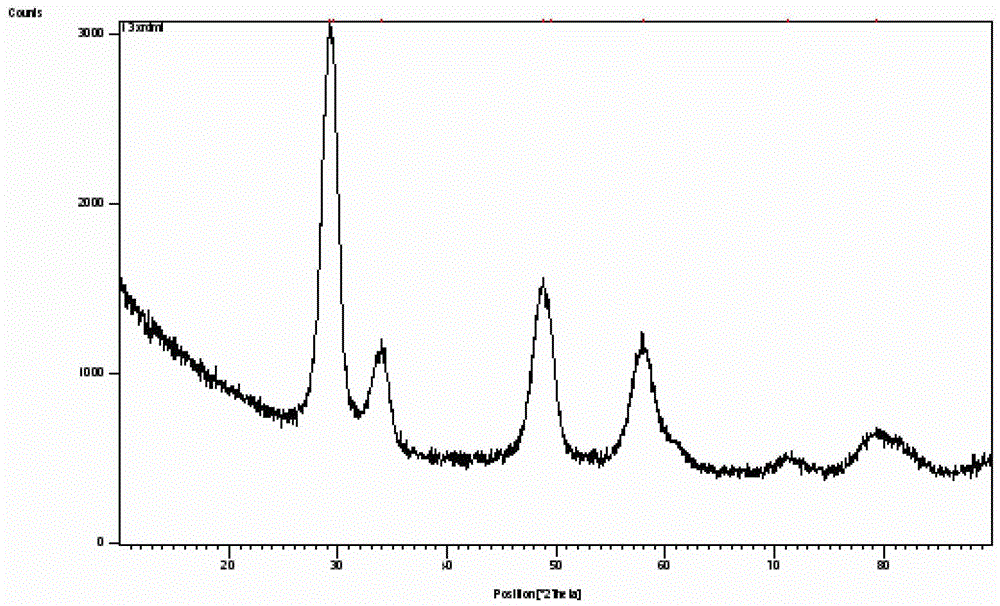

[0048] Zirconium oxychloride obtained after separation and purification of hafnium from zirconium and hafnium is used as the raw material of zirconium, and cerium nitrate is used as the source of cerium, according to Ce 0.5 Zr 0.5 o 2 Chemical formula is carried out batching, obtains 500 milliliters of 1M cerium-zirconium mixed solutions, and joins in the reactor. While stirring, slowly add a certain concentration of ammonia water / ammonium bicarbonate buffer solution (ammonia water / ammonium bicarbonate = 3:1) into the cerium-zirconium solution for precipitation reaction, the pH of the precipitation end point is 9, and the room te...

Embodiment 2

[0050]In the preparation process of atomic-grade hafnium products, zirconium oxychloride is used as zirconium raw material after industrial zirconium oxychloride is separated and purified from zirconium and hafnium, and a certain amount of cerium chloride and lanthanum chloride solution is added, according to Ce 0.4 Zr 0.5 La 0.1 o 2 Chemical formula is carried out batching, obtains 1M cerium zirconium lanthanum mixed solution 500 milliliters, and joins in the reactor. While stirring, slowly add 1.5M NaOH solution to the cerium-zirconium-lanthanum solution for precipitation reaction, the pH of the precipitation end point is 13, stir and age at room temperature 25°C for 1 hour, filter, wash, and dry in ordinary air at 120°C overnight Calcined at 600° C. for 3 hours to obtain a cerium-zirconium composite oxide product with a hafnium oxide content of 80 ppm. The fresh specific surface area of cerium-zirconium composite oxide is 110m 2 / g, the total pore volume is 0.50cm 3 ...

Embodiment 3

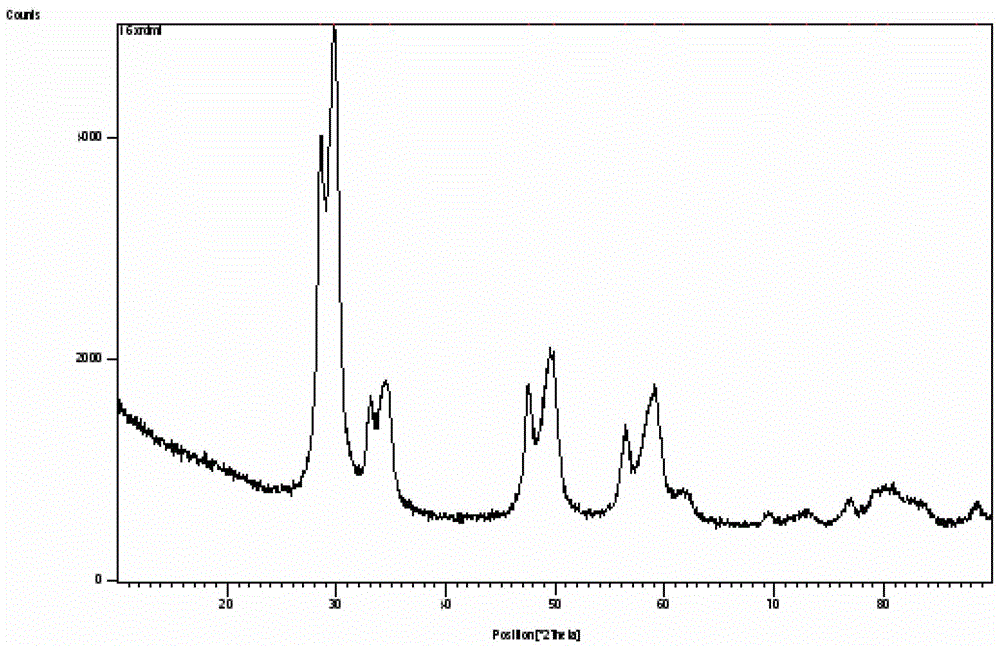

[0052] Zirconium oxynitrate obtained after separation and purification of hafnium from another zirconium and hafnium is used as the zirconium raw material, and the rare earth raw materials are cerium nitrate, lanthanum nitrate, and neodymium nitrate, according to Ce 0.2 Zr 0.6 La 0.1 Nd 0.1 o 2 Dosing according to the chemical formula to obtain 500 ml of 1M Ce-Zr-La-Nd mixed solution was added to the reactor, and then a certain amount of polyvinyl alcohol (5 wt% of the oxygen storage material) was added. In the state of stirring, slowly add 2M ammonia solution into the solution of cerium, zirconium, lanthanum, and neodymium for precipitation reaction. The precipitation temperature is 50°C, and the pH of the precipitation end point is 10. Stir and age at 50°C for 1 hour, and then directly spray dry at 250°C. Calcined at 600° C. for 3 hours to obtain a cerium-zirconium composite oxide product with a hafnium oxide content of 480 ppm. The fresh specific surface area of ceriu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com