Porous support for cartilage tissue engineering and preparation method thereof

A porous scaffold and cartilage tissue technology, applied in medical science, prosthesis, etc., can solve the problems of low porosity, solvent residue, and difficult to control pore size, so as to increase the strength and hardness of the gel and improve the stability of the gel structure , cross-linking and compounding sufficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

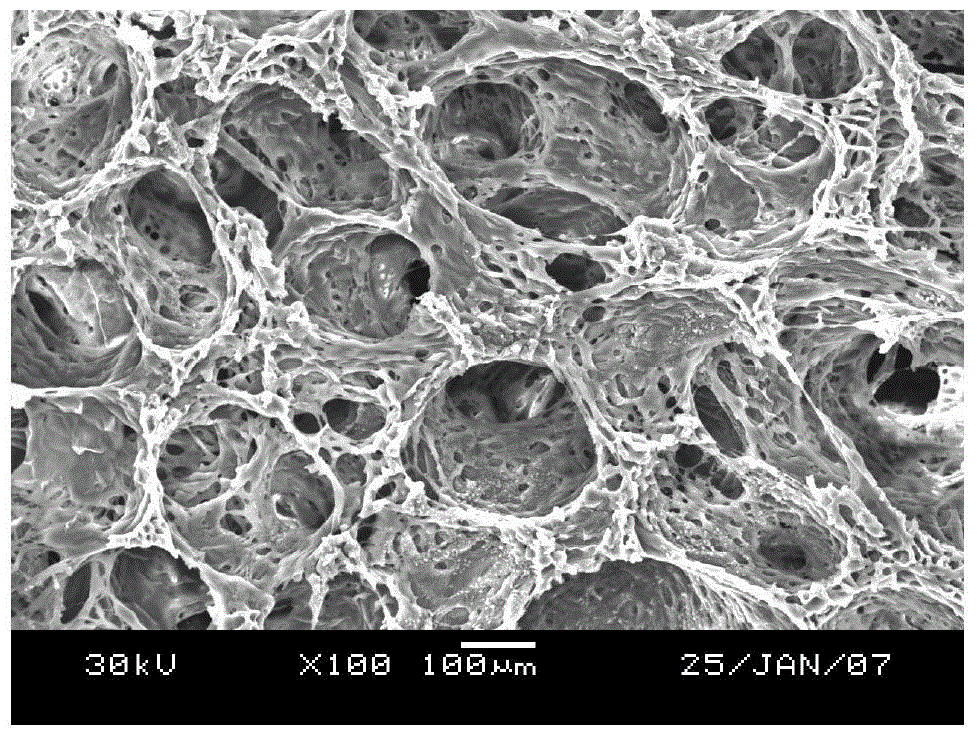

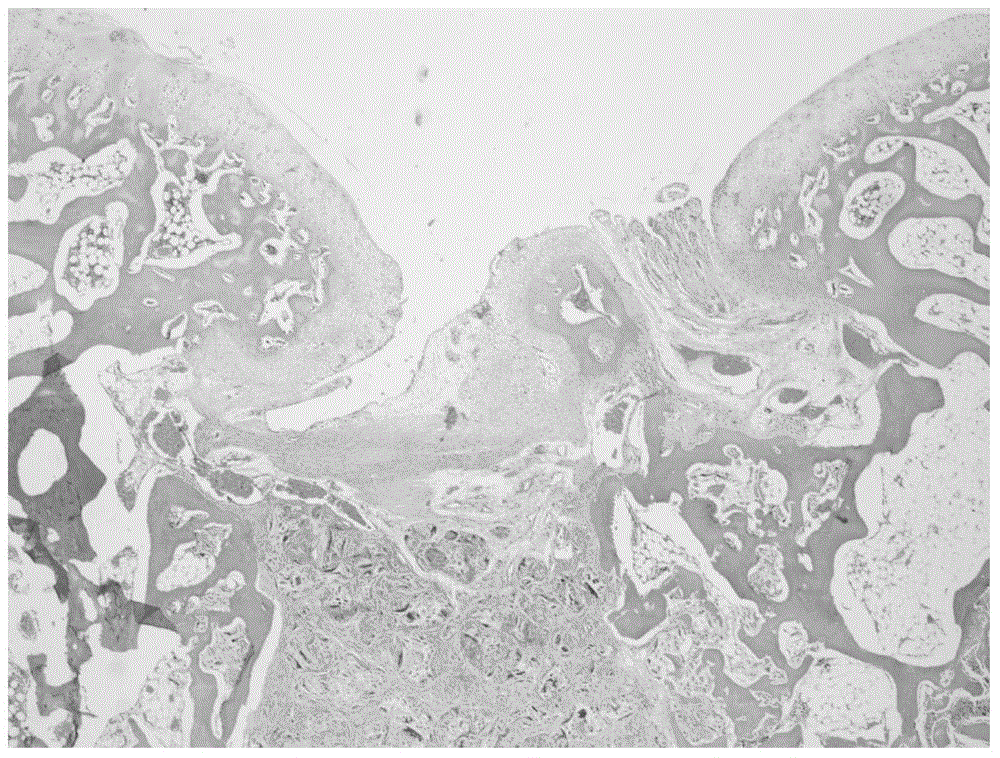

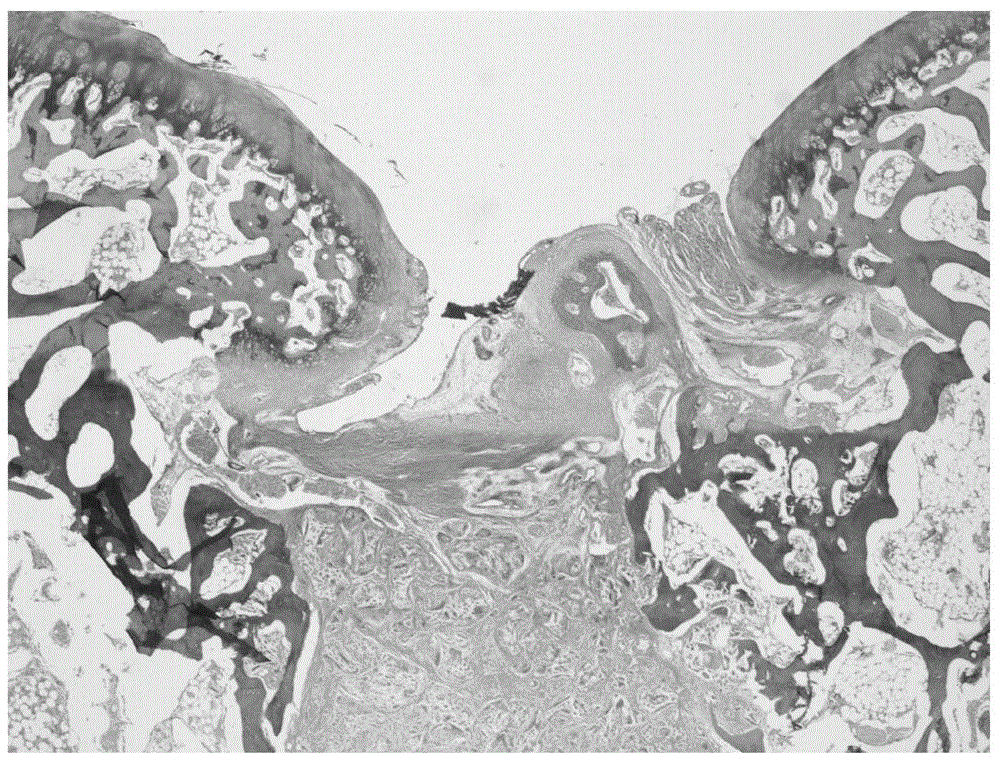

[0036] A porous scaffold for cartilage tissue engineering, which is a three-dimensional porous scaffold composed of κ-type carrageenan and chitosan with a molecular weight of 100,000 and a deacetylation degree of 90% in a mass ratio of 6:1, with a porosity of 89% and a pore size of 100- 150μm, compressive modulus 0.7MPa, tensile modulus 1.0MPa.

[0037] A method for preparing a porous scaffold for cartilage tissue engineering, comprising the following steps:

[0038] (1) Prepare 3% carrageenan solution with 60°C distilled water, prepare 0.6% chitosan solution with PH3 dilute hydrochloric acid solution, use beater 8000r / min respectively, beat for 30s;

[0039] (2) Blend the above-mentioned carrageenan and chitosan solution according to the carrageenan-chitosan solute mass ratio of 6:1, and stir with a magnetic stirrer at 1000 r / min to obtain a carrageenan-chitosan compound;

[0040] (3) beat the carrageenan-chitosan complex, add 120 μm sodium carbonate crystal powder (the mass...

Embodiment 2

[0044] A porous scaffold for cartilage tissue engineering, which is a three-dimensional porous scaffold composed of κ-type carrageenan and chitosan with a molecular weight of 200,000 and a degree of deacetylation of 85% in a mass ratio of 4:1, with a porosity of 92% and a pore size of 50 to 50%. 80μm, compressive modulus 1.2MPa, tensile modulus 2.2MPa.

[0045] A method for preparing a porous scaffold for cartilage tissue engineering, comprising the following steps:

[0046] (1) Prepare 5% carrageenan solution with 65°C distilled water, prepare 1% chitosan solution with PH3.6 dilute acetic acid solution, use beater 8500r / min respectively, beat for 25s;

[0047] (2) Blend the above carrageenan and chitosan solution according to the carrageenan and chitosan solute mass ratio of 5:1, and stir with a magnetic stirrer at 1500r / min to obtain a carrageenan-chitosan compound;

[0048] (3) beat the carrageenan-chitosan complex, add 100 μm sodium carbonate crystal powder (the mass rati...

Embodiment 3

[0052] A porous support for cartilage tissue engineering, which is a mixed glue of κ-type carrageenan, ι-type carrageenan and λ-type carrageenan (the mixing mass ratio is κ-type carrageenan: ι-type carrageenan: λ-type carrageenan=8: 1:1) and chitosan with a molecular weight of 330,000 and a deacetylation degree of 92% are a three-dimensional porous scaffold composed of a mass ratio of 8:1. Volume 2.0MPa.

[0053] A method for preparing a porous scaffold for cartilage tissue engineering, comprising the following steps:

[0054] (1) Prepare 10% carrageenan solution with 67°C distilled water, prepare 0.5% chitosan solution with PH3.3 dilute hydrochloric acid solution, use beater 10000r / min respectively, beat for 25s;

[0055] (2) blending the above-mentioned carrageenan and chitosan solution according to the carrageenan and chitosan solute mass ratio of 8:1, and stirring with a magnetic stirrer at 2000r / min to obtain a carrageenan-chitosan compound;

[0056] (3) beat the carrag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Compression modulus | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com