Preparation method for SLTON perovskite NOx powder

An oxynitride, perovskite-type technology, applied in chemical instruments and methods, calcium/strontium/barium compounds, tantalum compounds, etc., can solve the problems of limiting the production of SLTON powder, taking a long time, etc., to meet the requirements, preparation Low cost, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

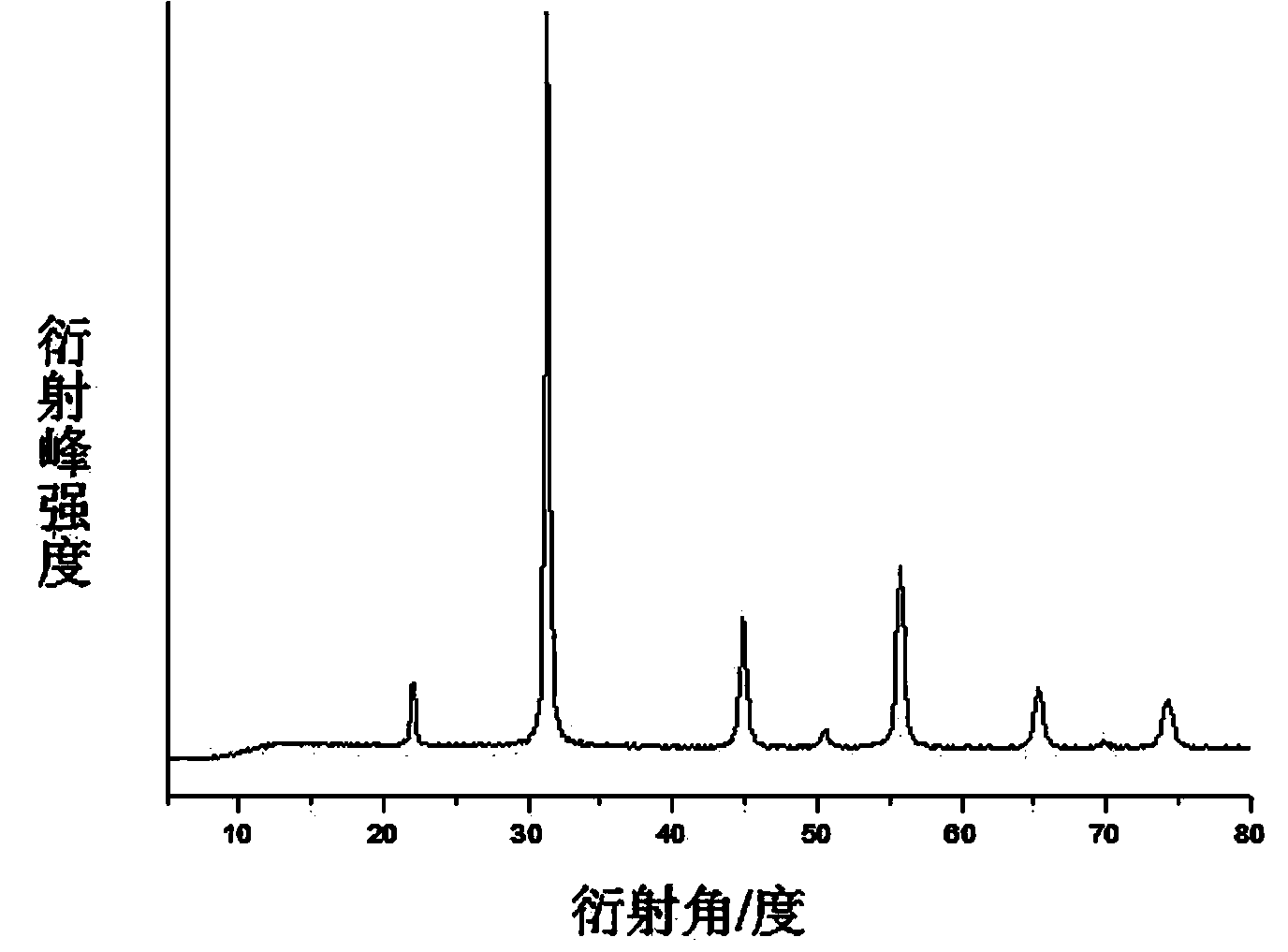

Embodiment 1

[0030] Accurately weigh strontium nitrate, lanthanum nitrate, tantalum pentachloride and urea in a molar ratio of 1:1:2:10 and put them into methanol aqueous solution (volume ratio of alcohol to water: 1:1) to stir and dissolve for more than 30 minutes . The solution was dried at 90 °C for 4 h, put into a mortar and ground finely, and the grinding time was 30 minutes. Put the above mixture into a crucible and put it into a box-type resistance furnace for calcination reaction at a reaction temperature of 800 °C and a reaction time of 4 h. After the reaction, it was naturally cooled to room temperature, and the product was nitrided under an ammonia atmosphere. The nitriding temperature was 850 °C for 6 hours. After cooling, the SLTON powder was obtained. The purity of its products is not less than 99.8%, and the impurity content: carbon is less than 0.12%; chlorine is less than 0.04%.

Embodiment 2

[0032] Accurately weigh strontium nitrate, lanthanum nitrate, tantalum pentachloride and citric acid in a molar ratio of 1:1:2:20 and put them into methanol aqueous solution (volume ratio of alcohol to water: 1:1) to stir and dissolve for more than 30 minutes. minute. The solution was dried at 200 °C for 6 h, put into a mortar and ground finely, and the grinding time was 30 minutes. Put the above mixture into a crucible and put it into a box-type resistance furnace for calcination reaction at a reaction temperature of 800 °C and a reaction time of 4 h. After the reaction, it was naturally cooled to room temperature, and the product was nitrided under an ammonia atmosphere. The nitriding temperature was 900 °C for 7 hours. After cooling, the SLTON powder was obtained. The purity of its products is not less than 99.7%, and the impurity content: carbon is less than 0.15%; chlorine is less than 0.04%.

Embodiment 3

[0034] Accurately weigh strontium chloride, lanthanum chloride, tantalum pentachloride and citric acid in a molar ratio of 1:1:2:20 and put them into methanol aqueous solution (alcohol-water volume ratio 1:1) and stir to dissolve. more than 30 minutes. The solution was dried at 200 °C for 6 h, put into a mortar and ground finely, and the grinding time was 30 minutes. The above mixture was put into a crucible and put into a box-type resistance furnace for calcination reaction at a reaction temperature of 800 °C and a reaction time of 5 h. After the reaction, it was naturally cooled to room temperature, and the product was nitrided under an ammonia atmosphere. The nitriding temperature was 900 °C for 8 hours. After cooling, the SLTON powder was obtained. The purity of its products is not less than 99.6%, and the impurity content: carbon is less than 0.15%; chlorine is less than 0.09%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com