Recycling treatment method of fly ash, chrome slag and electroplating sludge hazardous waste

A technology for electroplating sludge and hazardous waste, which is applied in the field of electroplating sludge hazardous waste recycling, fly ash, and chromium slag, can solve the problems of high toxicity, flammability, explosion, and strong corrosiveness of hazardous waste, and save money. Investment, reducing the greenhouse effect, the effect of small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

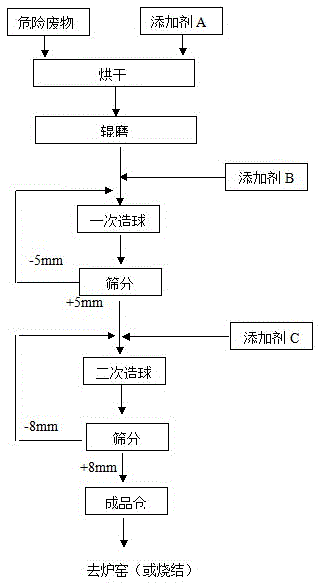

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0035] see figure 1 , the present invention fly ash, chromium slag, electroplating sludge hazardous waste resource treatment method, it comprises the steps:

[0036] 1. Collect fly ash, chromium slag, and electroplating sludge, and mix the fly ash, chromium slag, and electroplating sludge at a ratio of their mass greater than 0%;

[0037] 2. Add additive A to the ingredients and mix well;

[0038] The additive A is a mixture, mainly for reduction, chlorine absorption and catalysis, and is composed of coal powder or carbon black and quicklime, the mass percentage of coal powder or carbon black is 70-85%, and the mass percentage of quicklime is 15-30%; Additive A accounts for 15%-20% of the mass percentage of the whole ingredients; quicklime moisture is not considered, coal powder or carbon black moisture is generally required to be less than 7%, if the moist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com