Preparation method of chitosan-silk fibroin composite nanofiber multifunctional patch for promoting myocardial tissue regeneration and stem cell monitoring

A composite nanofiber, myocardial tissue regeneration technology, applied in the direction of bone/connective tissue cells, animal cells, vertebrate cells, etc., can solve the problems that are not conducive to artificial improvement and regulation, and cannot achieve sustained release of drugs or cytokines. The effect of promoting attachment and growth, inhibiting left ventricular remodeling, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

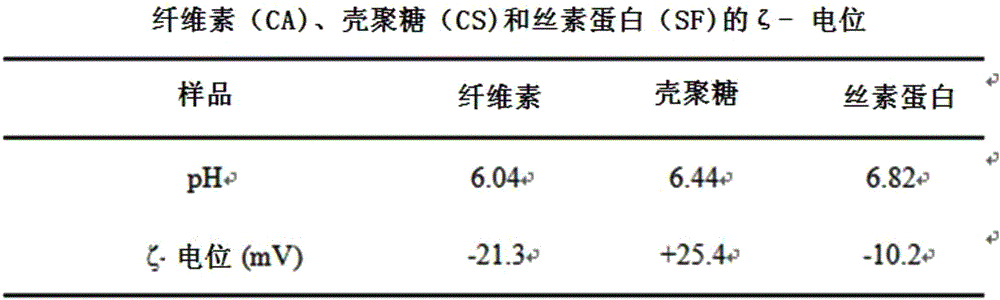

[0040] The preparation method of the chitosan-silk fibroin composite nanofiber multifunctional patch for promoting myocardial tissue regeneration and stem cell monitoring of the present invention comprises the following steps:

[0041] (1) Preparation of cellulose nanofiber base plate (Mat) by electrospinning technology;

[0042] (2) By layer-by-layer self-assembly (LBL), positively charged chitosan (CS) and negatively charged silk fibroin (SF) were alternately assembled layer by layer onto the surface of the cellulose nanofiber bottom plate obtained in step (1) , assemble 5.5-15.5 layers to form a chitosan-silk fibroin composite nanofibrous membrane;

[0043] (3) Plant AD-MSC or iPS-CPC seed cells labeled with green fluorescent protein (GFP) and firefly luciferase (Fluc) on the surface of the composite nanofiber membrane obtained in step (2); through three-dimensional co-cultivation, the obtained The chitosan-silk fibroin composite nanofiber multifunctional patch for promoti...

Embodiment 1

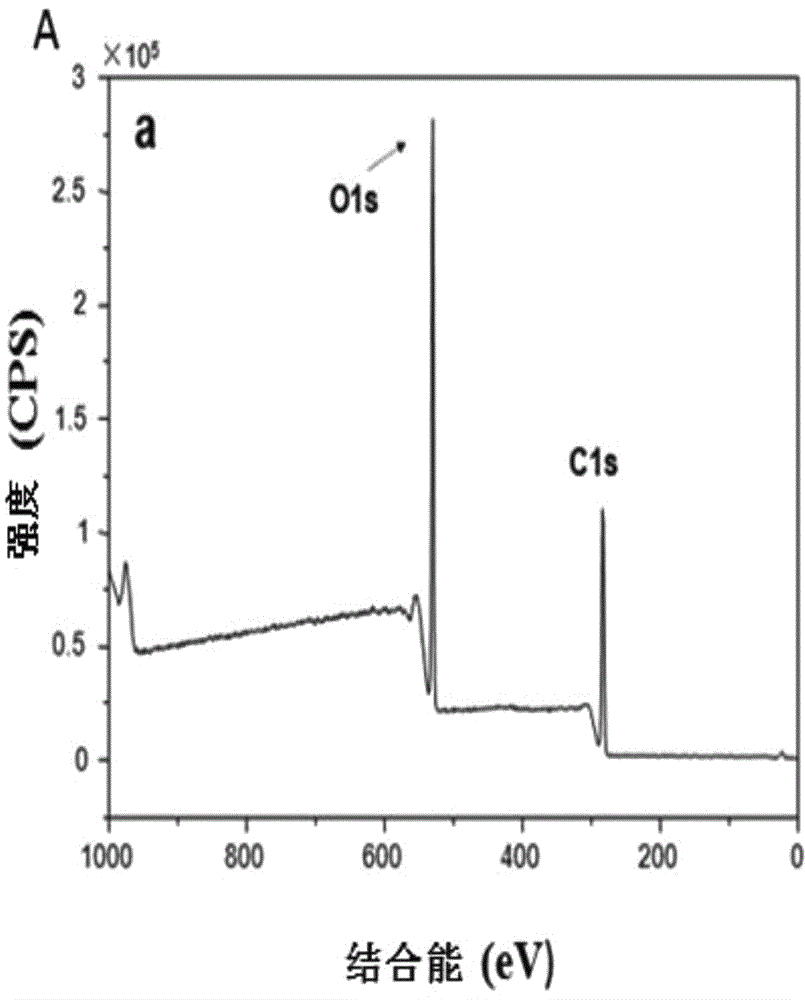

[0044] Example 1 Preparation of cellulose nanofiber base plate (Mat) by electrospinning technology

[0045] Example (1). The cellulose acetate (CA, Mn=3×10 4 Da, Aldrich Co., USA) was dissolved in acetone and dimethylacetamide (DMAc) mixed solution with a mass ratio of 2:1 at a mass concentration of 15%, and was sucked into a plastic syringe with a metal needle, and the inner diameter of the needle was 1 mm. The distance between the needle and the roller collector covered with aluminum foil was 20 cm, and the applied DC voltage was 16 kV. The syringe is driven by a syringe pump at a speed of 0.5ml / h, the drum rotates at a linear speed of 100 m / min, the ambient temperature is 25°C, the relative humidity is 40%, and the electrospinning time is 16 hours. The prepared CA nanofiber bottom plate was dried in vacuum at room temperature for 24 hours to remove the solvent. Then, the dried CA nanofiber base plate was hydrolyzed in 0.05 mol / L sodium hydroxide solution for seven days, ...

Embodiment 2

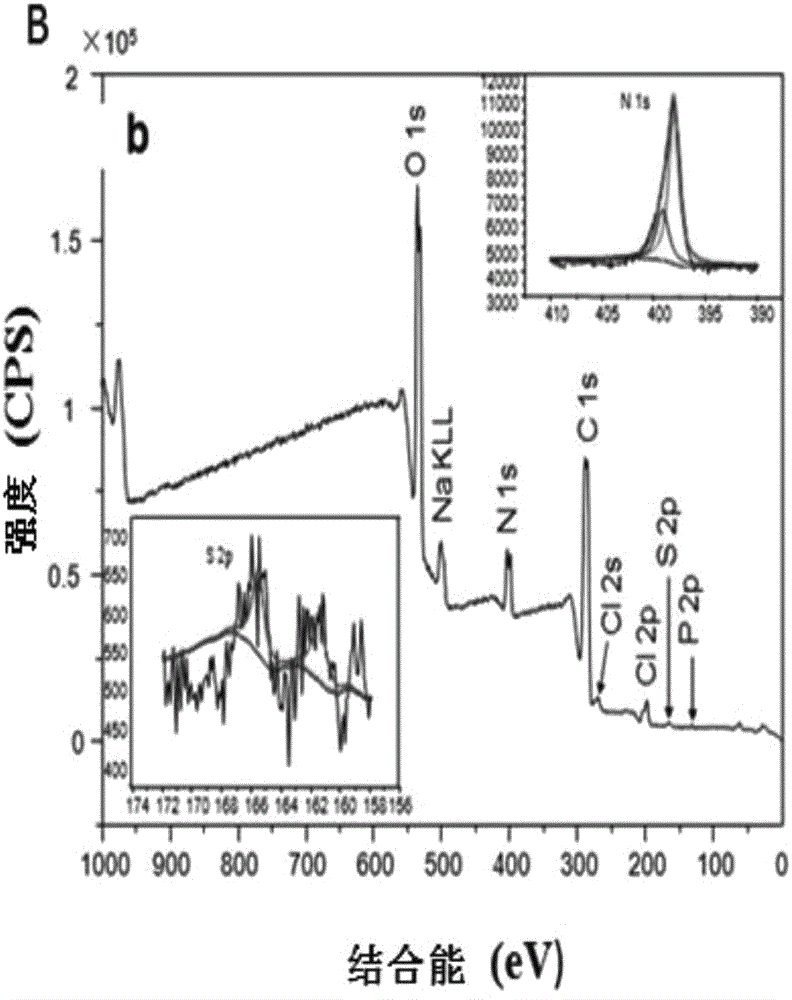

[0048] Formation of embodiment two chitosan-silk fibroin composite nanofiber membrane

[0049] Example (1) positively charged chitosan (CS, Mw=2.0×10 5 kDa, DD=92%, Zhejiang YuhuanOceanBiochemicalCo., China), using 2% acetic acid solution as a solvent to prepare a 1㎎ / L solution, adjusting the pH value to 5.0, negatively charged silk fibroin (SF, Aladdin Chemical Reagent Co., China) was made into 1㎎ / L aqueous solution, and the pH was adjusted to 5.3. The cellulose nanofiber bottom plate obtained in Example 1 was immersed in a positively charged chitosan (CS) solution for 20 minutes, and rinsed three times with 0.1 mol / L sodium chloride solution for 2 minutes each time. Then the nanofiber bottom plate was immersed in negatively charged silk fibroin (SF) solution for 20 minutes, and rinsed three times with 0.1 mol / L sodium chloride solution. 2 minutes each time. This process can make the surface of nanofibers covered with chitosan-silk fibroin (CS-SF) bimolecular layer, repeat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com