Conductive copper paste and preparation method and use thereof

A technology of copper paste and ultra-fine copper powder, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve problems such as hindering the development of electronic business, increasing production costs, etc. To achieve the effect of guaranteed performance, wide source and anti-oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

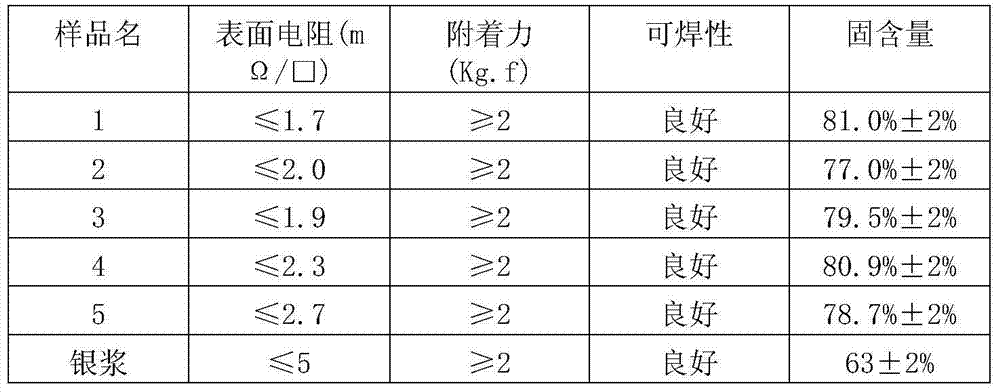

Embodiment 1

[0025] 1. Metal copper powder: choose ultra-fine copper powder with particle size d50=2μm, and the shape is spherical.

[0026] 2. Glass powder: choose glass powder with a particle size of 2 μm and a melting point of 550°C.

[0027] 3. Organic binder: dissolve 5% ethyl cellulose and 5% phenolic resin in 32.5% butyl carbitol acetate, add 42.5% terpineol, 10% Diethyl phthalate and 5% castor oil are mixed and stirred evenly to obtain an organic binder for use.

[0028] 4. Preparation of copper paste: Add the following substances by mass ratio: 78% ultrafine copper powder, 3% glass frit, 1.3% ascorbic acid and 0.2% SiO2 (50nm), 1% titanate coupling agent, 1% three Ethanolamine, 1% polyethylene glycol 200, and 14.5% organic binder were ground by a ball mill with a rotating speed of 510r / min for 6 hours to obtain a conductive copper paste. The copper paste was paste-like, bright red in color, and uniform and fine in appearance.

[0029] 5. Firing of the electrode: Print the prepar...

Embodiment 2

[0031] 1. Metal copper powder: choose ultra-fine copper powder with particle size d50=2μm, and the shape is spherical.

[0032] 2. Glass powder: choose glass powder with a particle size of 1 μm and a melting point of 600°C.

[0033] 3. Organic binder: dissolve 7% ethyl cellulose and 5% phenolic resin in 30.5% butyl carbitol acetate, add 42.5% terpineol, 10% Diethyl phthalate and 5% castor oil are mixed and stirred evenly to obtain an organic binder for use.

[0034] 4. Preparation of copper paste: add the following materials by mass ratio: ultrafine copper powder 74%, glass frit 3%, 1.8% oxalic acid and 0.2% SiO2 (80nm), 1% lecithin, 1.5% polyethylene glycol 200 , 1% KH-550, 17.5% organic binder, and after 8 hours of grinding by a 450r / min ball mill, a conductive copper paste was prepared. The copper paste was paste-like, bright red in color, and uniform and fine in appearance.

[0035] 5. Firing of the electrode: Print the prepared conductive copper paste on the ceramic sub...

Embodiment 3

[0037] 1. Metal copper powder: choose ultra-fine copper powder with particle size d50=3μm, and the shape is spherical.

[0038] 2. Glass powder: choose glass powder with a particle size of 2 μm and a melting point of 600°C.

[0039] 3. Organic binder: dissolve 5% ethyl cellulose and 5% phenolic resin in 32.5% butyl carbitol acetate, add 52.5% terpineol, 5% castor oil, mixed and stirred evenly to obtain an organic binder for use.

[0040] 4. Preparation of copper paste: Add the following materials by mass ratio: 74% ultrafine copper powder, 5% glass frit, 2.4% oxalic acid and 0.1% SiO2 (100nm), 0.7% KH-550, 0.8% triethanolamine, 0.8 %Polyethylene glycol 200, 16.2% organic binder, after grinding for 4 hours by a 550r / min ball mill, a conductive copper paste was obtained.

[0041]5. Firing of the electrode: Print the prepared conductive copper paste on the ceramic substrate by screen printing, dry it at 150°C and put it into the furnace at a ratio of hydrogen to nitrogen of 1:3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com