A kind of supported vanadium phosphorus oxide catalyst and preparation method thereof

A vanadium phosphorus oxide and catalyst technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as low specific surface area, increased catalyst manufacturing cost, and different crystal phases. The effect of high surface area, many surface active centers, and large porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

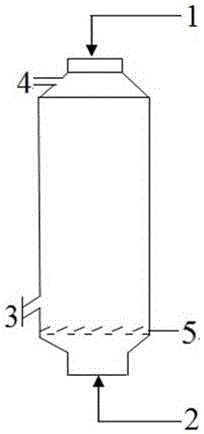

[0053] exist figure 1 In the ebullated bed reactor shown, 30.0 g of vanadium pentoxide was added from the feeding port 1; put N 2 Bubble into the reactor through the feed port 2 to keep the reaction liquid and solid particles in a "boiling" tumbling state. Raise the reaction temperature and keep it at 110±2°C, keep the reaction time for 3 hours; then add 72g of nano-silica into the reactor from the feeding port 1, and reflux for 4 hours; feed the concentrated 85% concentration from the feeding port 1. Phosphoric acid was 38.0 g, and the phosphorus / vanadium molar ratio was 1.0. Continue to maintain the "boiling" reaction for 6 hours, and discharge from the reaction material outlet 3 after the reaction is completed. After the reaction solution was cooled to room temperature, it was filtered, and the filter cake was rinsed three times with a small amount of isobutanol, and then the filter cake was placed in an enamel tray to dry naturally at room temperature, then dried in an ...

Embodiment 2

[0059] exist figure 1 In the ebullated bed reactor shown, 30 g of vanadium pentoxide, 0.3 g of ferric nitrate as auxiliary agent, 0.5 g of auxiliary zirconium nitrate were added from feeding port 1; 690 mL of isobutanol and benzyl alcohol mixed solution, isobutanol / benzyl alcohol Volume ratio 15:1. put N 2 Bubble into the reactor through the feed port 2 to keep the reaction liquid and solid particles in a "boiling" tumbling state. Raise the reaction temperature and keep it at 100±2°C, keep the reaction time for 4 hours; then add nano-silica 80g to the reactor from the feeding port 1, and reflux for 3 hours; Phosphoric acid 35.5g, phosphorus / vanadium molar ratio of 1.1, continued to maintain the "boiling" reaction for 6 hours, and discharged from the reaction material outlet 3 after the reaction was completed. After the reaction solution was cooled to room temperature, it was filtered, and the filter cake was rinsed three times with a small amount of isobutanol, and then the...

Embodiment 3

[0065] exist figure 1 In the ebullated bed reactor shown, 30.0 g of vanadium pentoxide; 690 mL of a mixed solution of isobutanol and benzyl alcohol, and a volume ratio of isobutanol / benzyl alcohol of 20:1 was added from feed port 1. The helium gas was blown into the reactor from the feed port 2 to keep the reaction liquid and solid particles in a "boiling" tumbling state. Raise the reaction temperature and keep it at 98±2°C, keep the reaction time for 4 hours; then add nano-silica 92g to the reactor from the charging port 1, and reflux for 4 hours; pass into the concentrated 95% concentration from the charging port 1. Phosphoric acid was 34.0 g, and the phosphorus / vanadium molar ratio was 1.0. Continue to maintain the "boiling" reaction for 8 hours, and discharge from the reaction material outlet 3 after the reaction is completed. After the reaction solution was cooled to room temperature, it was filtered, and the filter cake was rinsed three times with a small amount of iso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com