Catalytic synthesis method of salidroside

A synthesis method and technology of salidroside, applied in chemical instruments and methods, organic chemistry, production of bulk chemicals, etc., can solve the problems of high production cost and low yield, and achieve low cost, high product yield, The effect of improving catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

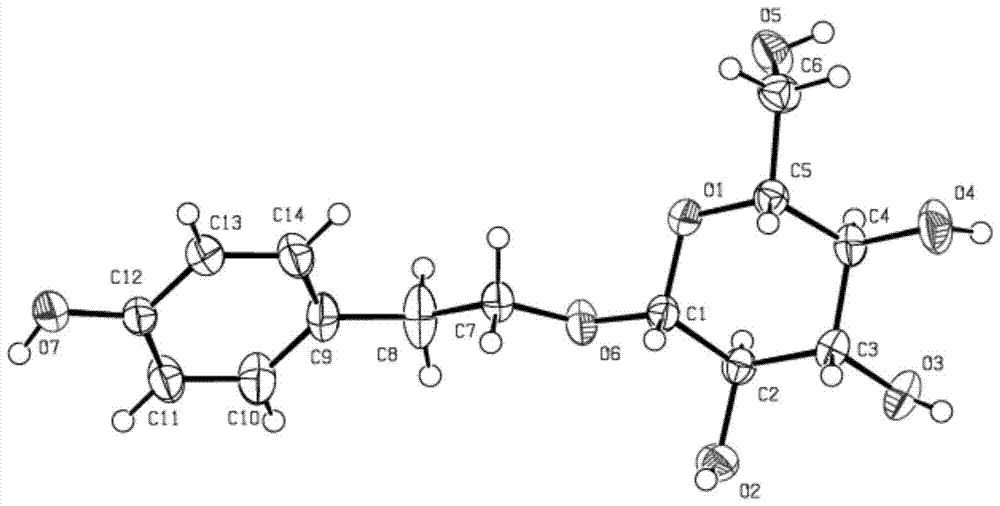

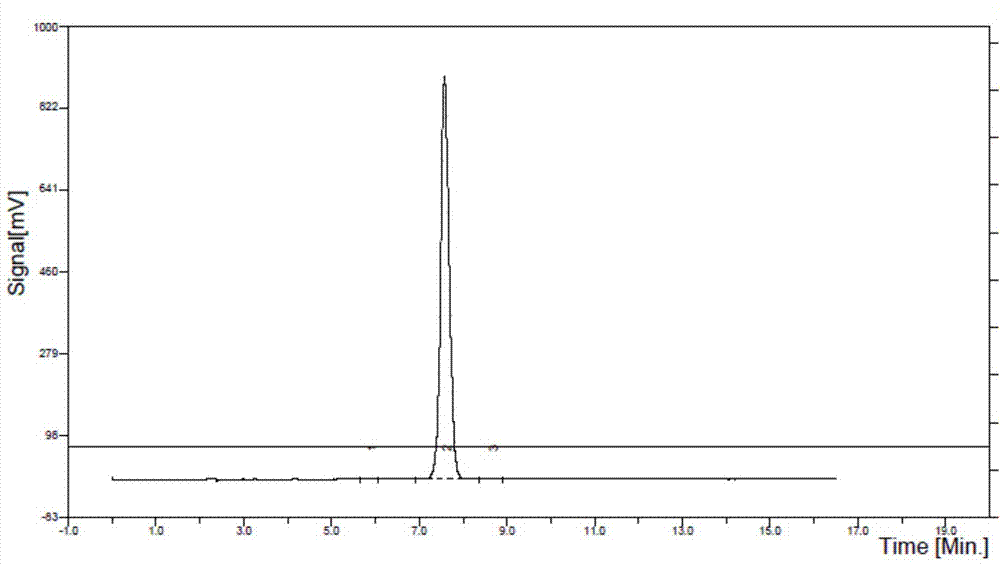

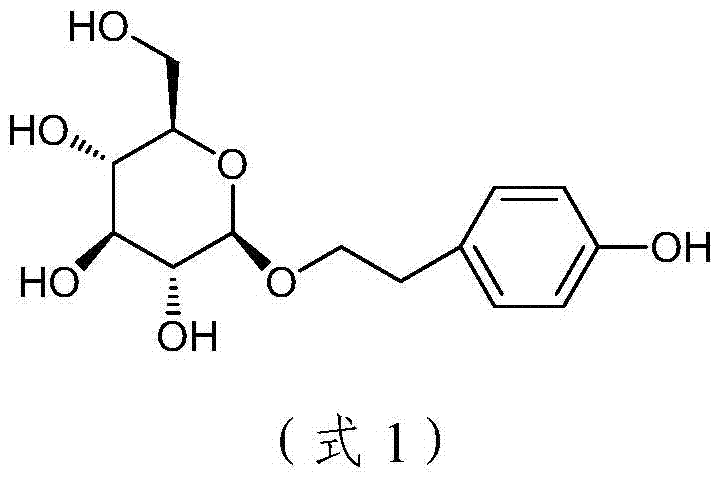

Image

Examples

Embodiment 1

[0044] (1) Synthesis of intermediate 4-benzyloxyphenethyl alcohol:

[0045] Dissolve 600g (4.348mol) of 4-hydroxyphenethyl alcohol in 1 liter of DMF, add 178g (4.45mol) of sodium hydroxide after dissolving, stir for half an hour, then add 481g (4.829mol) of benzyl chloride, TLC monitors that there is no raw material benzyl chloride Post-treatment, directly poured into ice water, stirred for half an hour, filtered, washed with water, and dried to obtain 842 g of white solid with a yield of 85%.

[0046] (2) Preparation of 2-(4-benzyloxyphenyl)ethyl-(2,3,4,6-O-tetra-acetyl)-β-D-glucopyranoside:

[0047] Add 273g (0.70mol) of peracetylglucose, 191.5g (0.84mol) of 4-benzyloxyphenethyl alcohol, 29g (0.21mol) of zinc chloride and 13.6g (0.14mol) of magnesium chloride directly into 1.5L of chloroform Stir, react at 60°C for 10 hours, and then remove the solvent to obtain off-white solid 2-(4-benzyloxyphenyl)ethyl-(2,3,4,6-O-tetra-acetyl)-β-D-pyran Glucoside 289g (0.51mol), yield 73...

Embodiment 2

[0065] Preparation of 2-(4-benzyloxyphenyl)ethyl-(2,3,4,6-O-tetra-acetyl)-β-D-glucopyranoside: 200g (0.513 mol), 196g (0.86mol) of 4-benzyloxyphenethyl alcohol, 129g (0.97mol) of aluminum trichloride, and 50g (0.513mol) of magnesium chloride were directly added to 1.2L of chloroform and stirred, reacted at 60°C for 10h, and precipitated , 200 g (0.36 mol) of an off-white solid was obtained, and the yield was 70%.

Embodiment 3

[0067] Preparation of 2-(4-benzyloxyphenyl)ethyl-(2,3,4,6-O-tetra-acetyl)-β-D-glucopyranoside: 279g (0.717 mol), 196g (0.86mol) of 4-benzyloxyphenethyl alcohol, 186g (0.717mol) of tin chloride, and 44g (0.717mol) of magnesium fluoride were directly added to 1.6L dichloroethane and stirred, and reacted at 60°C for 15h After precipitation, 281 g (0.49 mol) of an off-white solid was obtained, with a yield of 68%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com