Monodisperse transition metal nanocatalyst for Fischer-Tropsch synthesis as well as preparation method and application thereof

A nano-catalyst and transition metal technology, which is applied in the field of monodisperse transition metal nano-catalyst and its preparation, can solve the problems of aggravating the agglomeration of primary crystal grains and increasing the decomposition temperature of cobalt nitrate, and achieve excellent catalytic activity and product selectivity. Simple and convenient, the effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

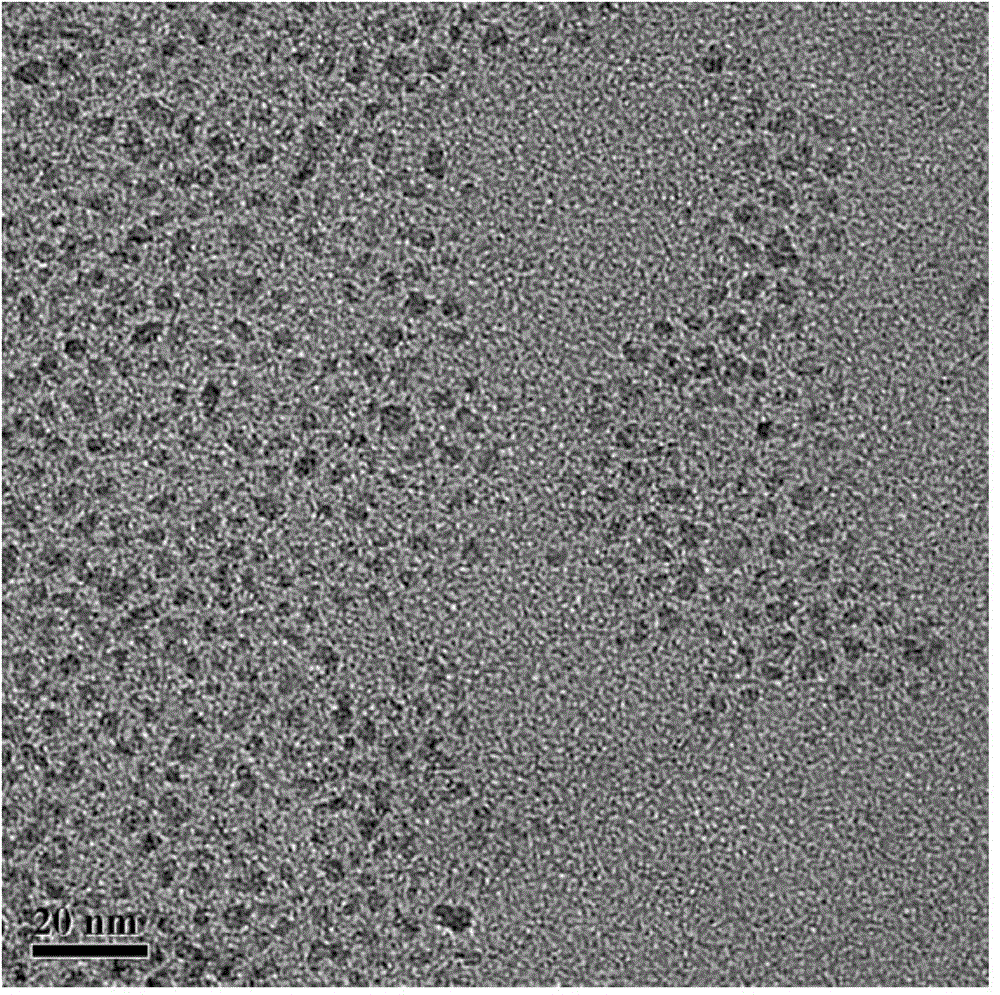

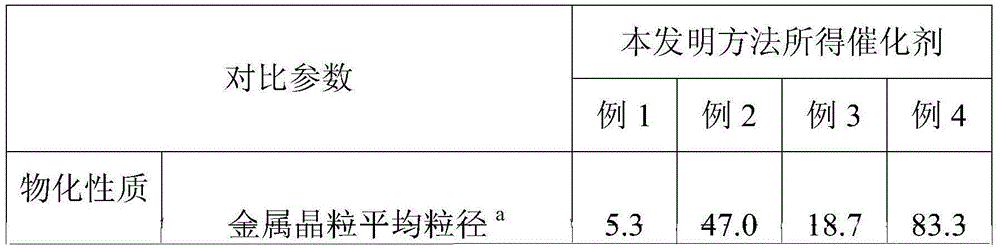

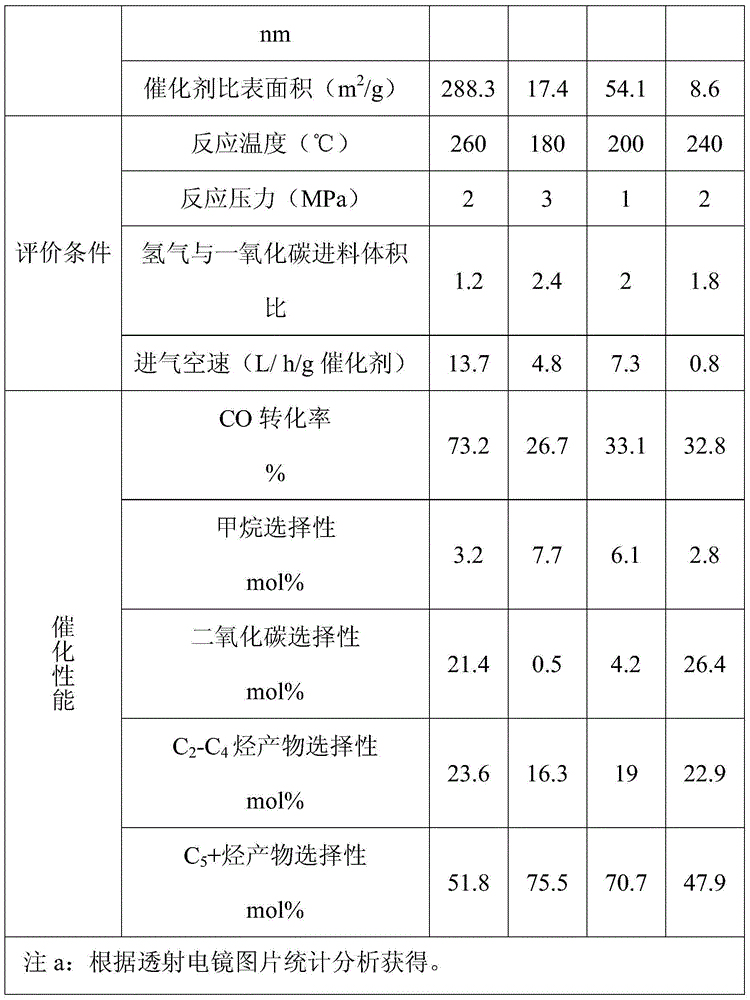

[0027] First dissolve 6 g of iron (III) acetylacetonate in 550 ml of 2-pyrrolidone solution (density of 1.116 g / ml), then add 3.5 g of 1,2-dodecanediol to the solution to obtain a mixed solution; then , under the condition of mechanical stirring, in the air atmosphere, the temperature of the mixed solution was raised to 160°C at a heating rate of 1°C / min; after being kept at 160°C for 120 minutes, it was naturally cooled to room temperature, and the gray-black nano-iron colloid was obtained Solution, add 250ml liquid paraffin and seal it for later use.

[0028] Transfer the prepared nano-iron colloidal solution together with liquid paraffin to a slurry bed reactor for direct Fischer-Tropsch synthesis reaction, wherein the reaction temperature is 260°C, the feed ratio range of hydrogen to carbon monoxide is 1.2, and the air inlet space velocity is 13.7L / h / g catalyst (inlet flow rate is 13L / h), reaction pressure is 2MPa. Under the above conditions, the performance evaluation re...

Embodiment 2

[0030] First dissolve 2.6g of cobalt(II) oxalate and 0.01g of ruthenium(III) nitrosyl nitrate in 250ml of dibenzyl ether solution (density 1.04g / ml), then add 10g of 1,2- cetanediol to obtain a mixed solution; then, under the condition of mechanical stirring, in an argon atmosphere, the temperature of the mixed solution was raised to 250°C at a heating rate of 10°C / min; Naturally cool to room temperature to obtain a deep purple nano-cobalt colloidal solution, add 250ml of liquid paraffin and seal it for later use.

[0031]Transfer the obtained nano-cobalt colloidal solution together with liquid paraffin to a slurry bed reactor for direct Fischer-Tropsch synthesis reaction, wherein the reaction temperature is 180°C, the feed ratio range of hydrogen to carbon monoxide is 2.4, and the air inlet space velocity is 4.8L / h / g catalyst (inlet flow rate is 5L / h), reaction pressure is 3MPa. Under the above conditions, the performance evaluation results of the catalyst are shown in Table...

Embodiment 3

[0033] Dissolve 4g of iron (III) acetylacetonate and 2g of cobalt (II) acetylacetonate in 450ml of benzyl alcohol solution (density 1.04g / ml), then add 9g of 1,2,4-butanetriol to the solution , to obtain a mixed solution; then, under the condition of mechanical stirring, in an air atmosphere, the temperature of the mixed solution was raised to 200°C at a heating rate of 5°C / min; That is, a dark gray iron-cobalt alloy nanocolloid solution was obtained, and 250ml of liquid paraffin was added to seal it for later use.

[0034] Transfer the prepared iron-cobalt alloy nano colloidal solution together with liquid paraffin to a slurry bed reactor for direct Fischer-Tropsch synthesis reaction, wherein the reaction temperature is 200°C, the feed ratio range of hydrogen to carbon monoxide is 2, the intake air The speed is 7.3L / h / g catalyst (inlet flow rate is 8L / h), and the reaction pressure is 1MPa. Under the above conditions, the performance evaluation results of the catalyst are sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com