Preservative paper for grape and production method thereof

A technology of grape fresh-keeping paper and fresh-keeping paper, which is applied in the directions of fruit and vegetable fresh-keeping, food preservation, layered products, etc., can solve the problems of low production efficiency, cumbersome production process, increased viscosity, etc., and achieves improved production efficiency and simple processing technology. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

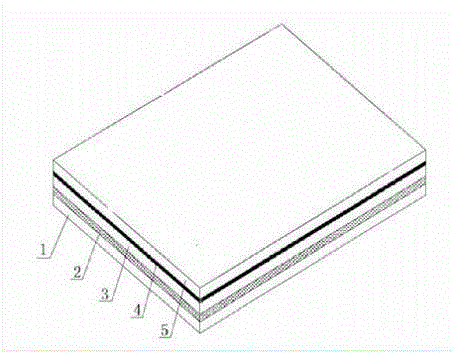

[0044] Preparation of three-layer base material with two layers of pharmaceutical fresh-keeping paper:

[0045] The formulation of the quick release layer agent is as follows:

[0046] Sodium metabisulfite: 40kg;

[0047] Sustained release agent: 0 kg;

[0048] Magnesium chloride: 10 kg;

[0049] Stearic acid: 30 kg;

[0050] Polyethylene hot melt adhesive: 20 kg;

[0051] The formula of the slow release layer medicament is as follows:

[0052] Sodium metabisulfite: 15 kg;

[0053] Sodium silicate: 35 kg;

[0054] Immediate release agent: 0 kg;

[0055] Stearic acid: 10 kg;

[0056] Polypropylene hot melt adhesive: 40 kg;

[0057] Substrate: the surface layer is non-woven fabric; the middle layer is breathable PE film; the bottom layer is paper plastic;

[0058] The surface layer and the base material of the middle layer sandwich the fast-release drug; the middle layer and the base material sandwich the slow-release drug.

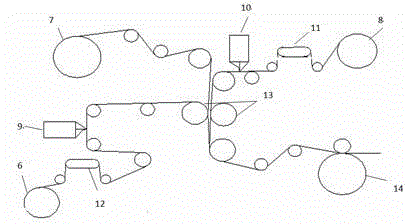

[0059] Production method: For the quick-re...

Embodiment 2

[0065] Preparation of three-layer base material with two layers of pharmaceutical fresh-keeping paper

[0066] The manufacture method of grape fresh-keeping paper in embodiment 2 is the same as embodiment 1, and just formula is different, and formula is as follows:

[0067] The formulation of the quick release layer agent is as follows:

[0068] Potassium metabisulfite: 70 kg;

[0069] Sustained release agent: 0 kg;

[0070] Calcium chloride: 0.2 kg;

[0071] Calcium stearate: 24.8 kg;

[0072] Polyester hot melt adhesive: 5 kg;

[0073] The formula of the slow release layer medicament is as follows:

[0074] Potassium metabisulfite: 40 kg;

[0075] Sodium carbonate: 0.2 kg;

[0076] Immediate release agent: 0 kg;

[0077] Calcium stearate: 24.8 kg;

[0078] Vinyl acetate hot melt adhesive: 35 kg;

[0079] Substrate: the surface layer is cloth; the middle layer is breathable pp film; the bottom layer is composite non-woven fabric.

[0080] Using method is the same a...

Embodiment 3

[0083] Preparation of three-layer base material with two layers of pharmaceutical fresh-keeping paper

[0084] The preparation method of grape fresh-keeping paper in embodiment 3 is the same as embodiment 1, just formula is different, and formula is as follows:

[0085] The formulation of the quick release layer agent is as follows:

[0086] Potassium bisulfite: 45 kg;

[0087] Sustained release agent: 0 kg;

[0088] Silica gel 15kg;

[0089] Magnesium stearate 10kg;

[0090] Ethylene-butyl acrylate hot melt adhesive 30kg;

[0091] The formula of the slow release layer medicament is as follows:

[0092] Potassium bisulfite 20kg;

[0093] Reduced microcrystalline lactitol alkyd acid 30 kg;

[0094] Immediate release agent 0kg;

[0095] Calcium stearate 35kg;

[0096] Acrylic resin hot melt adhesive 15kg;

[0097] Substrate: the surface layer is textured paper; the middle layer is breathable pet film; the bottom layer is hot-melt paper.

[0098] Using method is the same...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com