Method for increasing denitrification rate in wastewater treatment through goethite

A waste water treatment, nitrification and denitrification technology, applied in the direction of anaerobic digestion treatment, etc., can solve the problems of poor system shock resistance, difficulty in restarting the system, and increased operating costs, so as to reduce usage, reduce sewage treatment costs, reduce cumulative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The source of the inoculated denitrifying bacteria liquid in this embodiment is domesticated anaerobic tank sludge.

[0028] This embodiment simulates the effect of using goethite to improve the denitrification and denitrification rate in the anaerobic pond wastewater treatment process according to the following steps:

[0029] Adopt purchased natural goethite, crush it, grind it and pass through a 320 mesh sieve to obtain goethite powder;

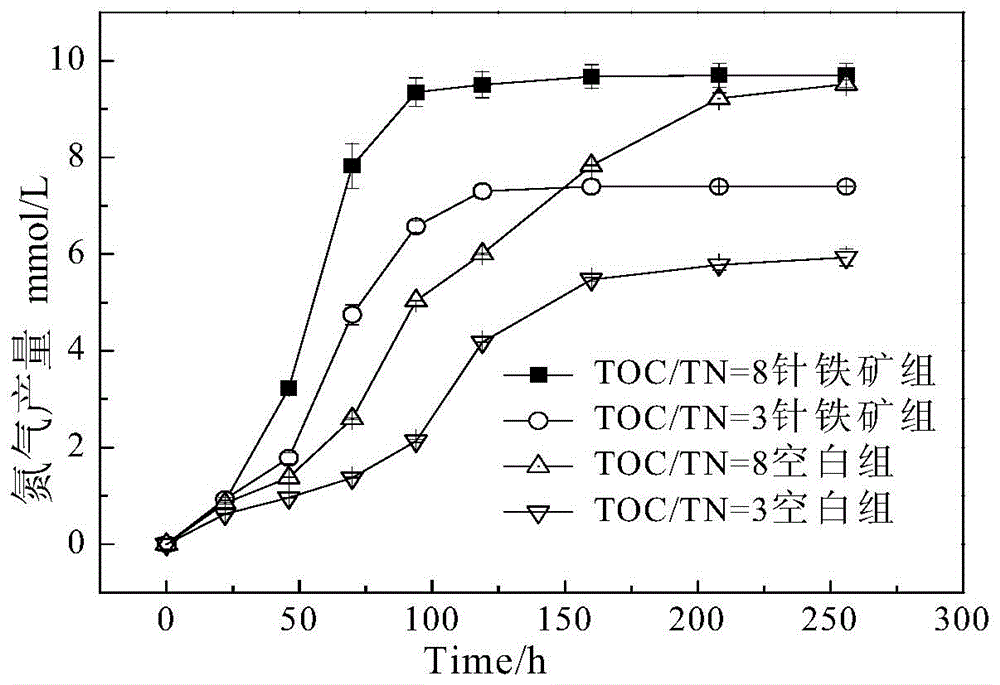

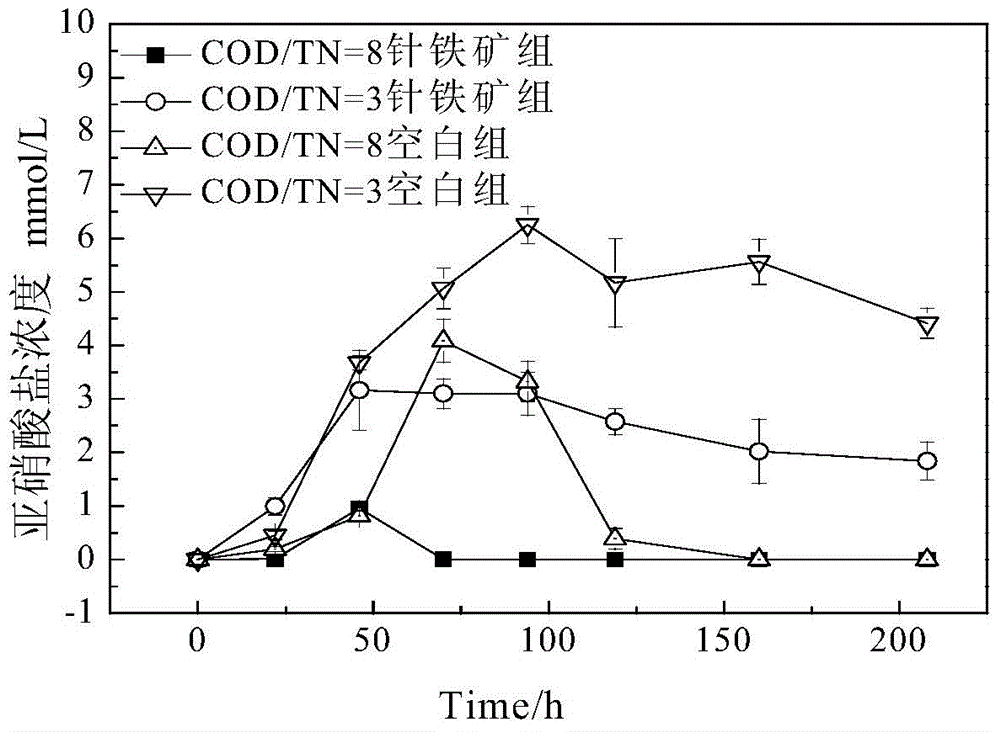

[0030] In the experiment, a 250mL serum bottle was used as a reactor, filled with 200mL of medium, and the COD / N was 8 and 3 respectively. Sodium acetate and glucose were selected as carbon sources for each carbon-nitrogen ratio, so the concentrations of sodium acetate were 34.7mmol / L and 13mmol / L respectively; the concentrations of glucose were 11.55mmol / L and 4.33mmol / L respectively. For each carbon-nitrogen ratio and carbon source, there are goethite group and blank group. The dosage of goethite in the goethite group was 0.45g / ...

Embodiment 2

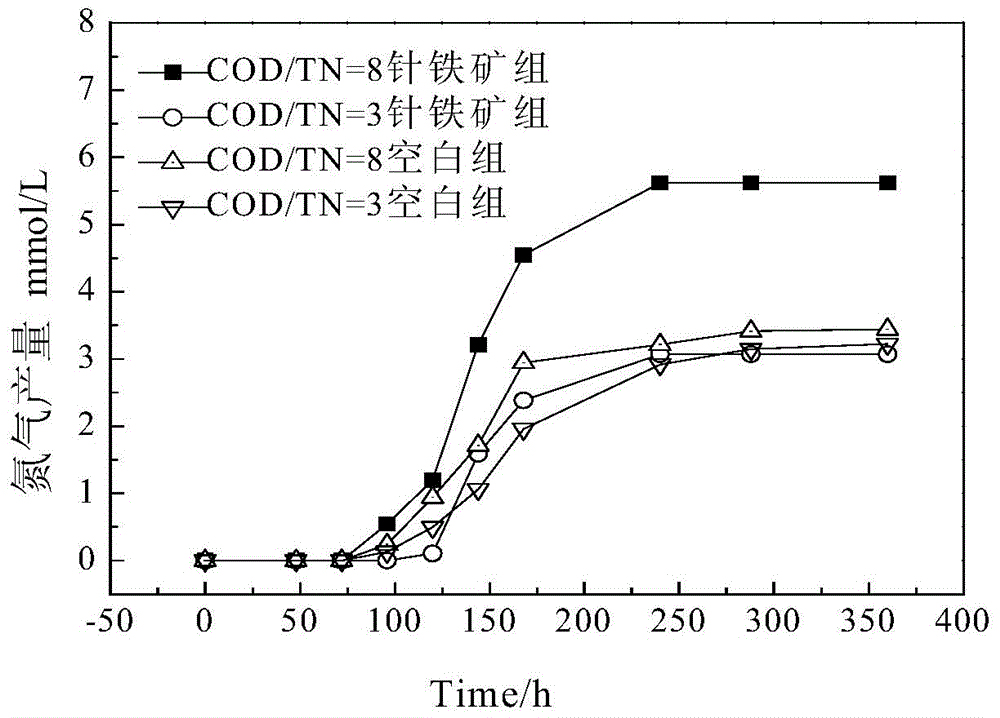

[0034] This embodiment simulates the effect of using goethite to increase the denitrification and denitrification rate in the wastewater treatment process according to the following steps:

[0035] Inoculate the anaerobic tank sludge of Anhui China Resources Snow Brewery 10% by volume into a reaction tank equipped with medium A and an effective volume of 3.5L. Air out in minutes. Then cultured at 30°C. Drain 0.6L of bacterial liquid every 4 days, and supplement the same volume of fresh medium A at the same time. After cultivating for 20 days, when the concentration of nitrate in the bacterial liquid discharged from the reaction tank is 0 mg / L, it indicates that the acclimation of the denitrifying bacterial liquid is completed, and the domesticated denitrifying bacterial liquid is obtained.

[0036] The composition of medium A is CH 3 COONa 34.7mmo / L, KNO 3 19.8mmol / L, MgSO 4 1.7mmol / L, KH 2 PO 4 7.4mmol / L, K 2 HPO 4 5.7mmol / L, pH=7.2±0.1.

[0037] Crushing natural go...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com