Preparation method for lithium-rich manganese based anode material hydroxide precursor

A technology of hydroxide and positive electrode materials, applied in battery electrodes, electrochemical generators, electrical components, etc., can solve problems such as low tap density, low material tap density, and poor material processing performance, and achieve uniform composition , the effect of controllable particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

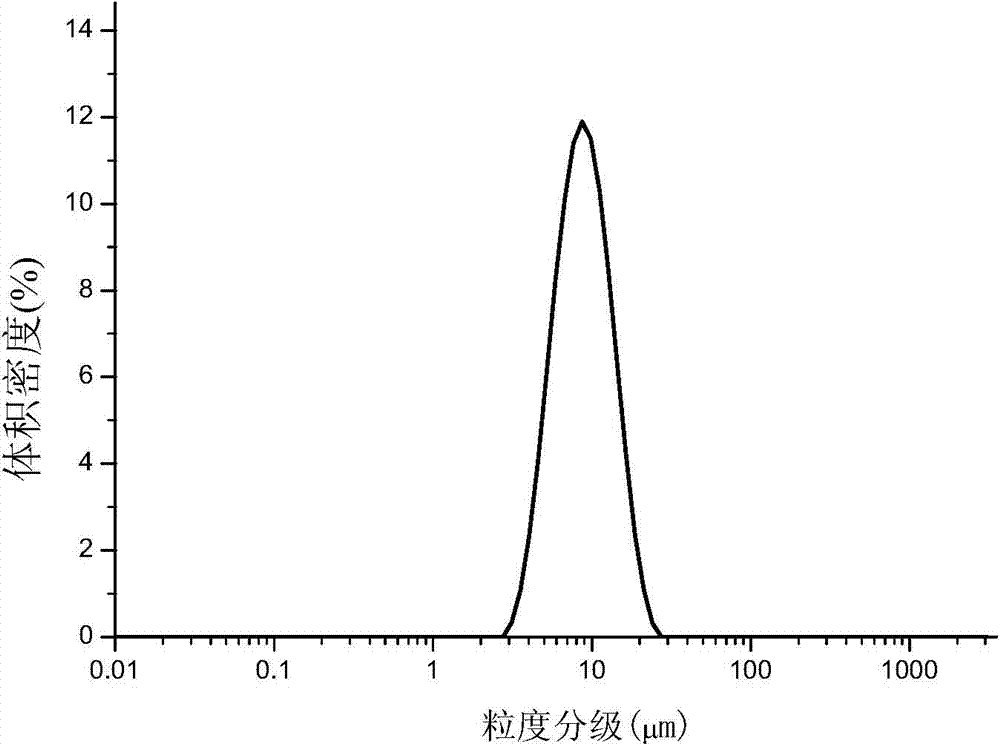

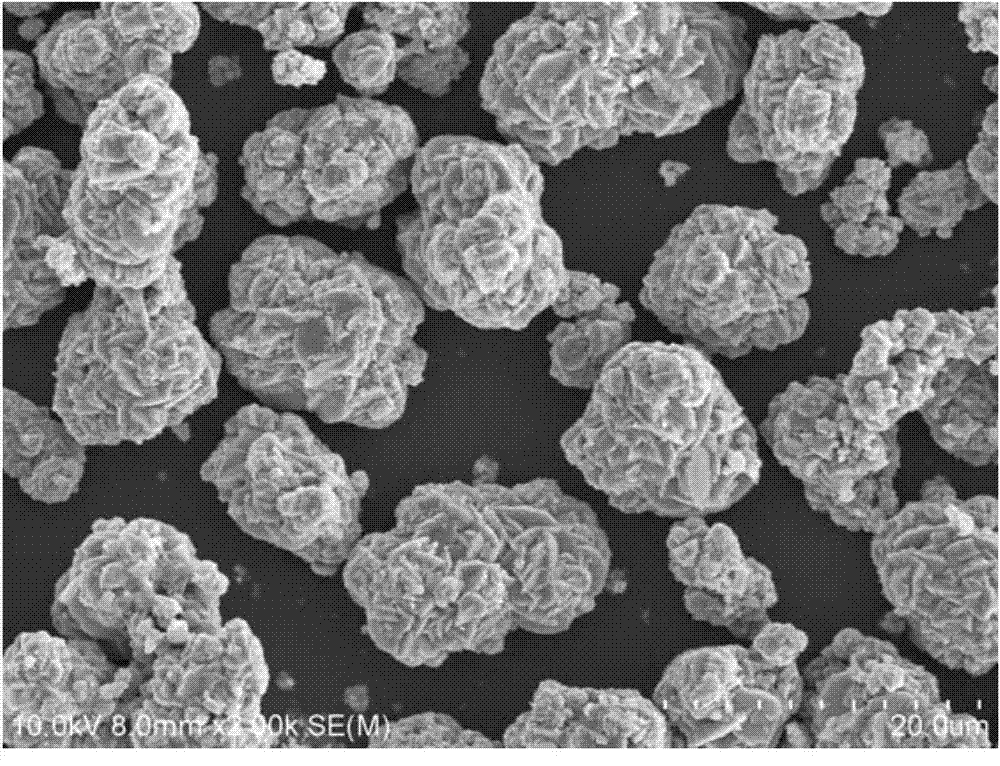

[0026] NiSO 4 、CoSO 4 , MnSO 4 According to molar ratio Mn: Ni: Co=55: 25: 20 ratio prepares the mixed aqueous solution of nickel salt, cobalt salt, manganese salt, the mixed ion concentration of nickel, cobalt, manganese is 1mol / L, preparation contains 0.2% polyacrylamide 8mol / L sodium hydroxide solution, prepare a composite complexing agent solution containing EDTA, chitosan and ammonia water, and then pump the mixed aqueous solution of nickel salt, cobalt salt, manganese salt, alkali solution, and complex complexing agent solution at the same time In the reaction kettle, the water bath temperature is 70°C, the stirring speed is 1000rpm, and the average molar concentration of EDTA in the control reaction solution is 0.15mol / L; the average mass concentration of chitosan in the reaction solution is 18%; the ammonium ion in the reaction solution The average molar concentration is 3mol / L, and the pH value is controlled at 11.5, the average residence time is more than 15 hours,...

Embodiment 2

[0028] Ni(NO 3 ) 2 , Co(NO 3 ) 2 , Mn(NO 3 ) 2 Prepare a mixed aqueous solution of nickel salt, cobalt salt, and manganese salt at a molar ratio of Mn:Ni:Co=65:15:20. The mixed ion concentration of nickel, cobalt, and manganese is 2.5mol / L, and the preparation contains 0.05% polyethylene 3mol / L potassium hydroxide solution of pyridine, prepare complex complexing agent solution containing EDTA, chitosan concentration and ammonia water, then mix aqueous solution of nickel salt, cobalt salt, manganese salt, alkali solution, complex complexing agent solution at the same time Pumped into the reaction kettle in parallel, the temperature of the water bath is 70°C, the stirring speed is 800rpm, the average molar concentration of EDTA in the control reaction solution is 0.05mol / L; the average mass concentration of chitosan in the reaction solution is 0.04%; The average molar concentration of ammonium ions is 0.2 mol / L, and the pH value is controlled at 9, the average residence tim...

Embodiment 3

[0030] NiCl 2 、CoCl 2 , MnCl 2Prepare a mixed aqueous solution of nickel salt, cobalt salt, and manganese salt at a molar ratio of Mn:Ni:Co=70:20:10. The mixed ion concentration of nickel, cobalt, and manganese is 0.8mol / L, and the preparation contains 0.01% polyethylene 1mol / L lithium hydroxide solution of imine, prepare complex complexing agent solution containing EDTA, chitosan and ammonia water, then mix aqueous solution of nickel salt, cobalt salt, manganese salt, alkali solution, and complex complexing agent solution at the same time Pumped into the reaction kettle in parallel, the temperature of the water bath is 40°C, the stirring speed is 100rpm, the average molar concentration of EDTA in the control reaction solution is 0.0001mol / L; the average mass concentration of chitosan in the reaction solution is 0.01%; The average molar concentration of ammonium ions is 0.1mol / L, and the pH value is controlled at 9, the average residence time is more than 24 hours, and the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com